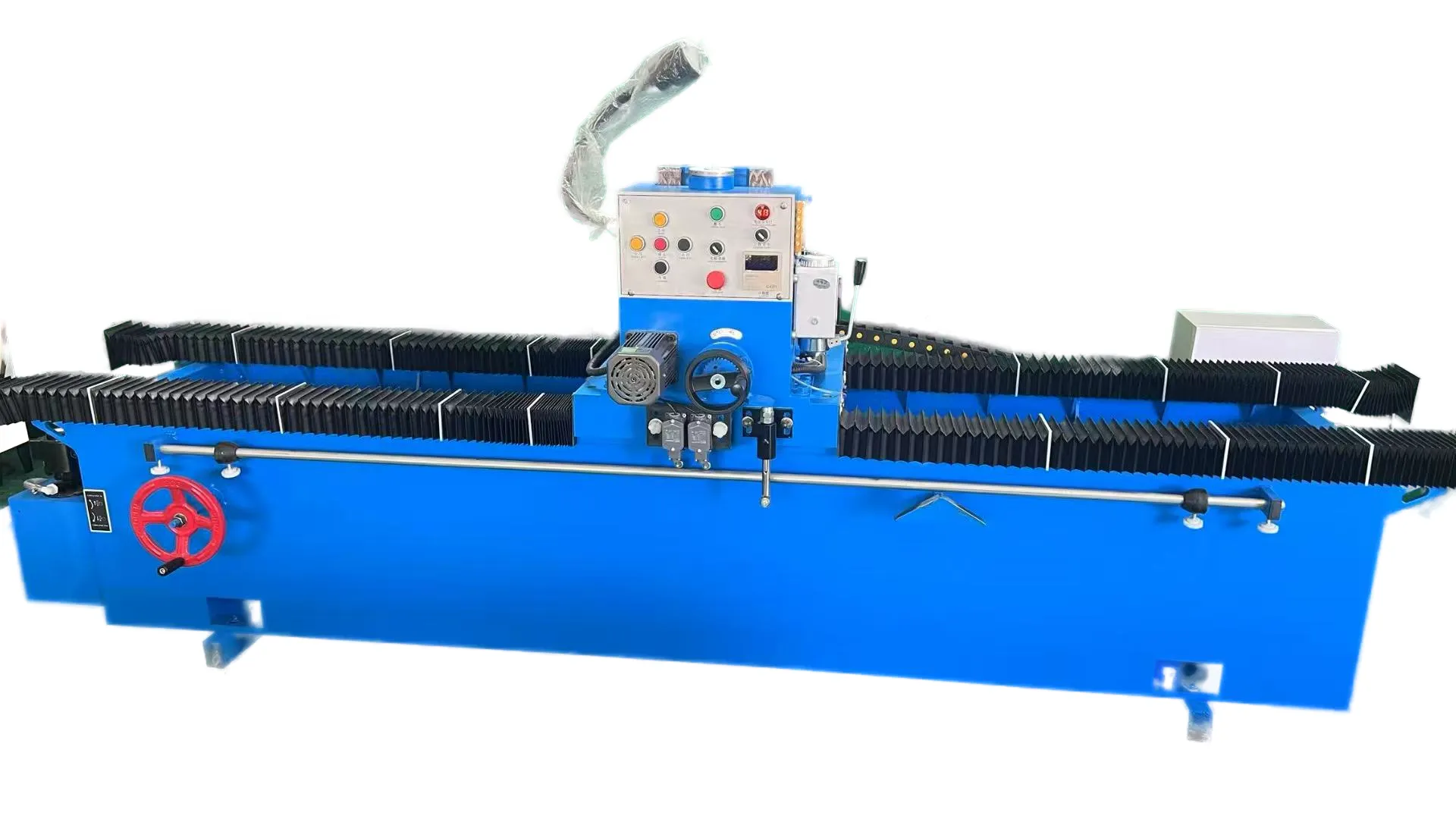

Specialist Grinder for Plastic Crusher & Pelletizer Knives

Restore perfect cutting edges to your plastic crusher, granulator, and pelletizer blades. Our automatic grinder ensures consistent material quality, reduces fines, and maximizes your production uptime.

Get Your Solution Quote

Advantages for Your Recycling Line

Ensure Uniform Particle Size

Perfectly sharp blades reduce fines and produce consistent, high-value recycled plastic flakes and pellets.

Minimize Production Downtime

Bring sharpening in-house. Quickly restore blade edges to keep your crushers and granulators running and profitable.

Extend Blade Lifespan

Precise, automated grinding removes minimal material, maximizing the number of sharpens per blade and reducing tooling costs.

Built for 24/7 Operations

Heavy-duty, welded steel construction designed to withstand the demanding environment of a non-stop recycling facility.

Simple 4-Step Sharpening Process

1. Mount Worn Crusher Blade

Easily secure your dull knife onto the powerful magnetic worktable.

2. Set Precise Cutting Angle

Adjust the table to the exact angle required for your specific application.

3. Start Automated Cycle

The machine runs the complete grinding and cooling cycle automatically.

4. Restore Production-Ready Edge

Re-install your perfectly sharpened blade and resume production.

Engineered for Performance

Key Components

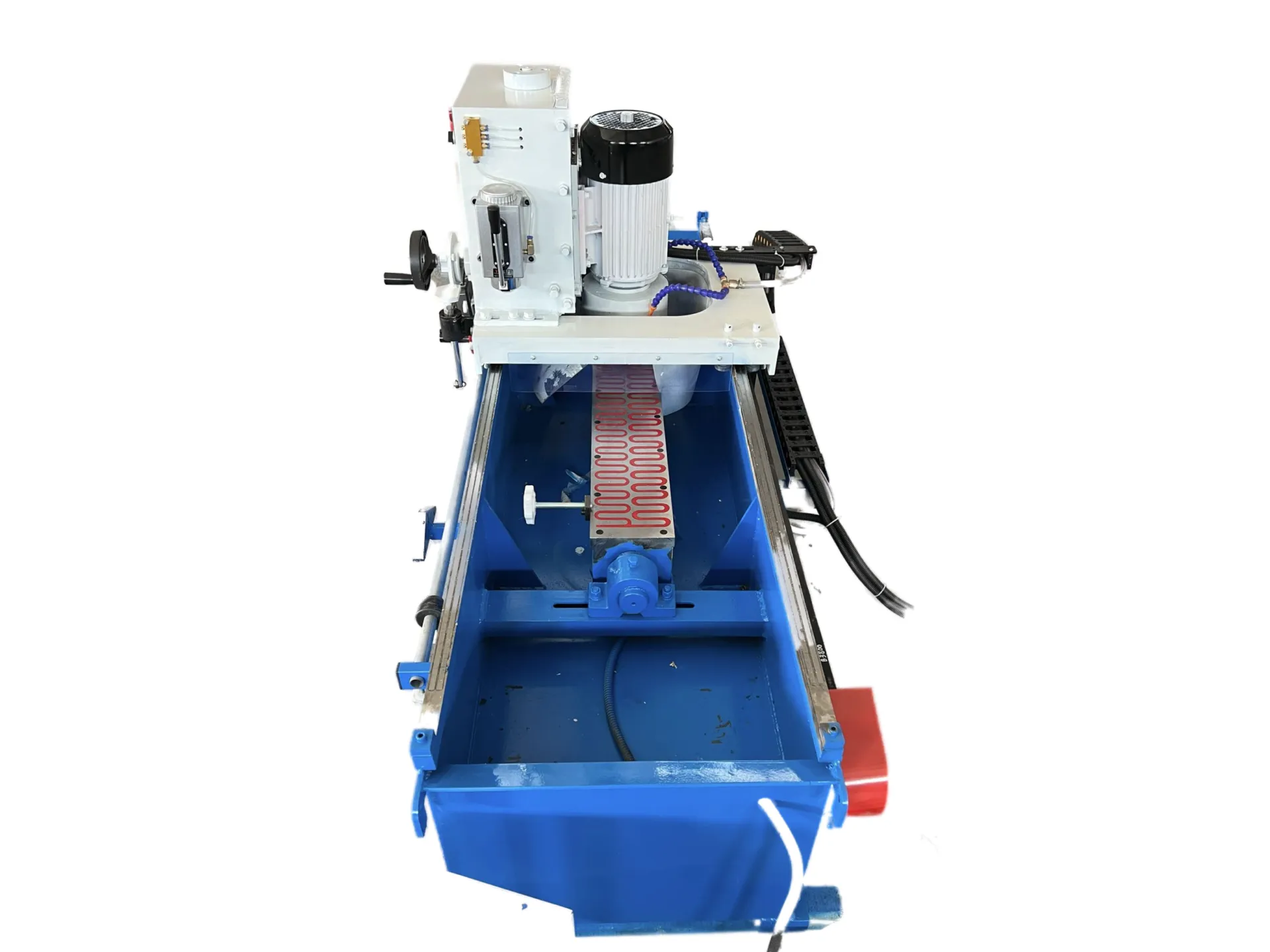

Powerful Grinding Motor

3 kW pure copper motor provides ample power to handle high-hardness tool steel blades from your crushers.

Adjustable Magnetic Worktable

Rotates 0–90° to achieve precise cutting angles for various types of granulator and pelletizer knives.

Reliable Electric Control

Durable, industrial-grade components in a mobile cabinet, designed for reliability in a factory environment.

High-Flow Cooling System

Prevents blade overheating during grinding, preserving the temper and hardness of your valuable tools.

Technical Parameters

| Parameter | Details |

|---|---|

| Maximum Knife Length | ≤ 1 meter, Width ≤ 250 mm |

| Magnetic Worktable Area | 900 × 150 mm |

| Grinding Head Motor | 3 kW (pure copper) |

| Travel Motor Power | 550 W gear reduction motor |

| Pump Motor Power | 40 W (external water tank) |

| Work Table Rotation | 0–90°, with locking handwheel |

| Grinding Feed | Belt drive, automatic/manual |

| Grinding Wheel Size | 200 × 32 × 110 mm |

| Machine Structure | Steel plate welded, main body ≥ 6 mm |

| Dimensions (L×W×H) | 2100 × 1100 × 1000 mm |

| Weight | Approx. 550 kg |

Watch a Crusher Blade Being Sharpened

Get a Grinding Solution for Your Recycling Line

Industry-Specific Questions

What types of plastic recycling knives can this machine handle?

This grinder is ideal for a wide range of recycling blades, including those from plastic crushers, granulators, shredders, and pelletizers. It handles various materials like D2 tool steel and can be configured for knives with tungsten carbide inserts.

How does blade sharpness impact the quality of my recycled material?

Critically. Sharp blades provide a clean cut, resulting in uniform particle size, fewer fines (dust), and lower energy consumption. This improves the quality and sale value of your final product, such as PET flakes or PP/PE pellets.

Can this machine improve our production line’s efficiency?

Absolutely. By bringing sharpening in-house, you eliminate shipping times and costs associated with outsourcing. This drastically reduces downtime, allowing for more frequent blade changes and keeping your production line at peak performance.

What is the typical ROI for a machine like this?

The return on investment is typically seen within months. It comes from three areas: 1) Savings from eliminating third-party sharpening services, 2) Increased revenue from higher-quality, more consistent recycled material, and 3) Reduced operational costs due to less downtime.