Material Handling

Chain Waste Conveyor for Recycling & Waste Handling

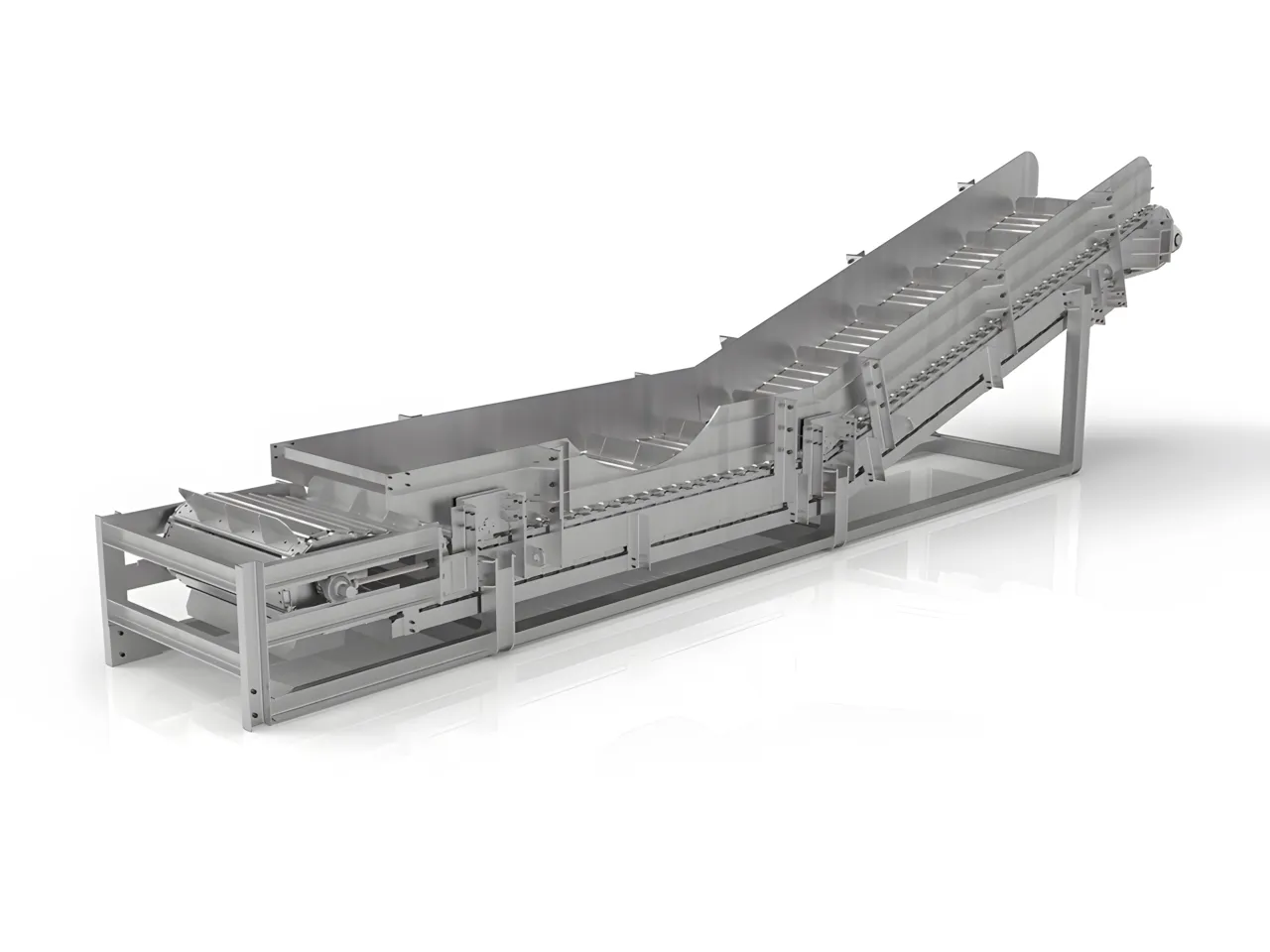

Move bulky, heavy, or abrasive materials with a rugged chain-driven conveyor (drag chain / scraper conveyor). Built for steady throughput, low spillage, and easy integration with shredders, sorting lines, and washing systems.

Why Use a Chain Waste Conveyor?

Chain conveyors are designed for tough material handling where belt conveyors can struggle—especially with sharp, wet, or heavy waste streams.

Heavy-Duty Load Handling

Engineered for high bulk density and impact loads, making them ideal for MSW, C&D waste, and bulky recyclables.

Built for Abrasion

Scraper flights and liners can be selected for abrasive feedstocks (glass, grit, soil) to extend service life.

Stable, Controlled Transfer

Consistent conveying helps keep downstream equipment fed evenly, supporting stable shredder and sorter performance.

Configurable Layout

Customize length, incline angle, covers, and discharge points to match your plant footprint and process flow.

Key Components

A simple, robust design: a heavy-duty chain circulates on sprockets, moving material via scraper flights along a reinforced trough or frame.

Chain & Flights

The conveyor’s core. Select chain pitch, flight spacing, and wear materials based on load, abrasiveness, and moisture.

Frame / Trough

Reinforced structure that supports the load and guides the chain. Optional liners protect high-wear zones.

Drive & Tensioning

Gear motor, sprockets, and tensioning ensure smooth motion. VFD control enables speed matching to upstream/downstream machines.

Feed & Discharge Interfaces

Hoppers, chutes, and discharge gates are designed to reduce spillage and maintain a consistent material bed depth.

Controls & Safety

Emergency stops, guarding, and overload protection help prevent jams and protect operators. Interlocks can be added for full-line control.

How the Chain Conveyor Works

A circulating chain drives scraper flights along a trough or frame, transporting waste from the feed zone to the discharge with controlled speed and minimal backflow.

Feed

Material is loaded via hopper, chute, or upstream conveyor. Infeed baffles can stabilize the bed depth.

Convey

Scraper flights drag material along the trough while the chain circulates around sprockets for continuous transfer.

Control

Speed is adjusted (often by VFD) to match line throughput, reduce surges, and prevent overfeeding downstream equipment.

Discharge

Material exits through a controlled discharge point (end discharge or side discharge), ready for shredding, sorting, or washing.

Applications in Recycling Lines

Chain conveyors are widely used for waste transfer, buffering, and controlled feeding—especially where materials are bulky, wet, or abrasive.

MSW & Sorting Facilities

Transfer waste between receiving hoppers, screens, and sorting stations with stable feeding and reduced spillage.

Plastic Recycling Plants

Feed single-shaft shredders and protect downstream quality control by integrating a metal detector.

C&D & Industrial Waste

Handle irregular, abrasive debris and bulky fractions where conventional belt conveyors may be prone to damage.

Technical Specifications (Typical)

Every project is customized to feedstock and plant layout. Use the table as a starting point, and we’ll confirm sizing after you share material photos and target throughput.

| Item | Typical Range / Options | Selection Notes |

|---|---|---|

| Conveyor Type | Drag chain / scraper conveyor / apron-style chain | Choose based on material size, abrasion, and incline requirements. |

| Trough / Belt Width | 600–1600 mm (custom) | Wider troughs increase capacity but require more drive power and structure. |

| Conveyor Length | 6–30 m (custom) | Layout-driven; include maintenance access and inspection points. |

| Conveying Speed | 5–25 m/min (VFD adjustable) | Slower speeds can reduce carryback, dust, and wear in abrasive applications. |

| Drive System | Gear motor + sprockets; overload protection | Motor sizing depends on load, incline angle, and friction/wear liner choice. |

| Construction | Carbon steel; optional stainless steel in wet/corrosive areas | Add covers, drainage, and corrosion protection for wet waste streams. |

| Wear Protection | Replaceable liners, hardened flights, sealed bearings | Recommended for sand/grit, glass fines, and high-impact feed. |

| Safety & Controls | Guards, emergency stops, interlocks, VFD | Integrate with shredder/sorter PLC for line stop, jam detection, and sequencing. |

Need a full waste line? Pair with a debaler, shredder, and downstream separation systems.

Maintenance & Safety Considerations

Simple preventive maintenance keeps conveying stable and reduces unexpected downtime from chain stretch, misalignment, or jam events.

Daily Checks

- Remove trapped debris at infeed/discharge zones.

- Inspect chain tension and abnormal noise/vibration.

- Verify guards and E-stops function properly.

Weekly / Monthly

- Lubricate where applicable and inspect sprocket wear.

- Check flight wear and liner condition; replace as needed.

- Confirm bolt tightness on drive and frame.

Jam Prevention

- Use proper infeed control to avoid overload surges.

- Consider metal detection and pre-sorting for tramp metal.

- Add torque limiters/overload protection in the drive.

Frequently Asked Questions

What materials can a chain waste conveyor handle?

Typical feedstocks include mixed municipal solid waste (MSW), construction & demolition debris, bulky plastics, wet waste streams, and abrasive materials with grit or glass fines. We size chain, flights, and liners based on your specific material.

Chain conveyor vs. belt conveyor: which is better for waste?

Chain conveyors are preferred for heavy, sharp, wet, or abrasive waste because they are more resistant to puncture and can be built with wear liners. Belt conveyors can be more energy-efficient for lighter, cleaner materials and long-distance transfer.

How do I choose width, speed, and incline?

Selection depends on throughput target, bulk density, maximum piece size, and layout. We recommend sharing material photos/videos plus the upstream/downstream machine capacities so we can size the trough width and motor power and set a stable conveying speed (often VFD-controlled).

What options help reduce odor, dust, and leakage?

Typical upgrades include covered troughs, sealed access doors, drainage design for wet waste, and controlled transfer chutes. For dust-prone streams, we can add enclosure interfaces for extraction or misting systems.

What maintenance is required?

Routine checks focus on chain tension/alignment, sprocket wear, and flight/liner wear. Preventive maintenance reduces jam risk and keeps conveying stable, especially in abrasive or wet environments.

Get a Quote for a Chain Waste Conveyor

Share your waste type, max piece size, desired capacity, and plant layout. We’ll recommend the right conveyor configuration and integration plan.