High-Efficiency PET Bottle Washing Line: Transform Plastic Waste into High-Value Flakes

Our fully automated system is designed for recyclers and manufacturers to address challenging contamination and high operating costs, producing 99.5% pure rPET flakes for premium markets.

Zatražite prilagođenu ponuduStruggling With Common Recycling Challenges?

Traditional recycling methods are often inefficient and unprofitable. Our system converts your biggest operational headaches into competitive advantages.

Pain Point: Contaminated Bales, Poor Flake Quality?

Our Solution: Our multi-stage washing process, featuring a hot washer and high-speed friction scrubbers, eliminates over 99.5% of stubborn contaminants like glue, oil, and labels, ensuring your final product meets premium standards.

Pain Point: High Operating & Labor Costs?

Our Solution: An intelligent water recycling system reduces consumption by up to 50%, while full automation reduces labor requirements by 2-3 operators per shift, directly boosting your profit margins.

Pain Point: Frequent Downtime & Maintenance?

Our Solution: We use wear-resistant alloy steel (D2/SKD-11) and corrosion-proof stainless steel (SUS304) for all critical components, guaranteeing 24/7 reliability and minimizing costly downtime.

Engineered for Maximum Performance and ROI

Unmatched Purity

Achieve premium-grade rPET flakes with a purity of 99.5% and total impurities below 100 ppm.

Potpuno automatizirano upravljanje

PLC smart control system allows for one-touch operation, real-time monitoring, and reduced human error.

Eco-Friendly & Cost-Efficient

Optimized water circulation and energy-saving motors significantly lower your operational expenses.

Durability & Low Maintenance

Built with high-quality, robust materials designed for continuous, long-term operation with minimal upkeep.

Modular & Customizable

Systems from 500 to 6,000 kg/h can be tailored to your specific raw materials, site layout, and output goals.

Turnkey Solutions & Support

We provide end-to-end service, from plant design and installation to operator training and lifetime technical support.

From Bales to Pure Flakes: Our Process

Each stage is meticulously engineered for maximum efficiency and cleaning power.

1. Automated Bale Breaker

Funkcija: Reliably breaks apart highly compressed PET bottle bales, ensuring a consistent, steady flow of material into the line.

Technical Features: High-torque motors, heavy-duty construction, and adjustable speed control to handle even the most compacted bales.

2. Trommel Screen

Funkcija: A critical pre-cleaning stage that tumbles bottles to remove smaller, heavy contaminants like sand, glass, and metal fragments.

Technical Features: Customizable screen perforations, wear-resistant drum, and an optimized rotation angle to maximize separation efficiency.

-Display.webp?fit=crop&ar=1:1&auto=format,compress&fm=webp)

3. Wet Granulator (Crusher)

Funkcija: Simultaneously crushes bottles into uniform flakes and performs an initial pre-wash, using water to cool the blades and flush away contaminants.

Technical Features: V-type rotor design for efficient cutting, hardened D2/SKD-11 steel blades, and interchangeable screens for precise flake size control.

4. Hot Washer System

Funkcija: The key to high-quality flakes. Uses heated water (85-95°C) and chemical agents to dissolve and strip away tough glues, oils, and residues.

Technical Features: Insulated SUS304 stainless steel tank, high-speed friction agitator, and automated temperature and dosing controls for consistent results.

5. Sink/Float Separation Tank

Funkcija: Uses water density to precisely separate heavier PET flakes (which sink) from lighter polyolefins like PP/PE caps and labels (which float).

Technical Features: Full SUS304 stainless steel construction, surface-skimming paddles, and a bottom screw conveyor for automated, continuous separation.

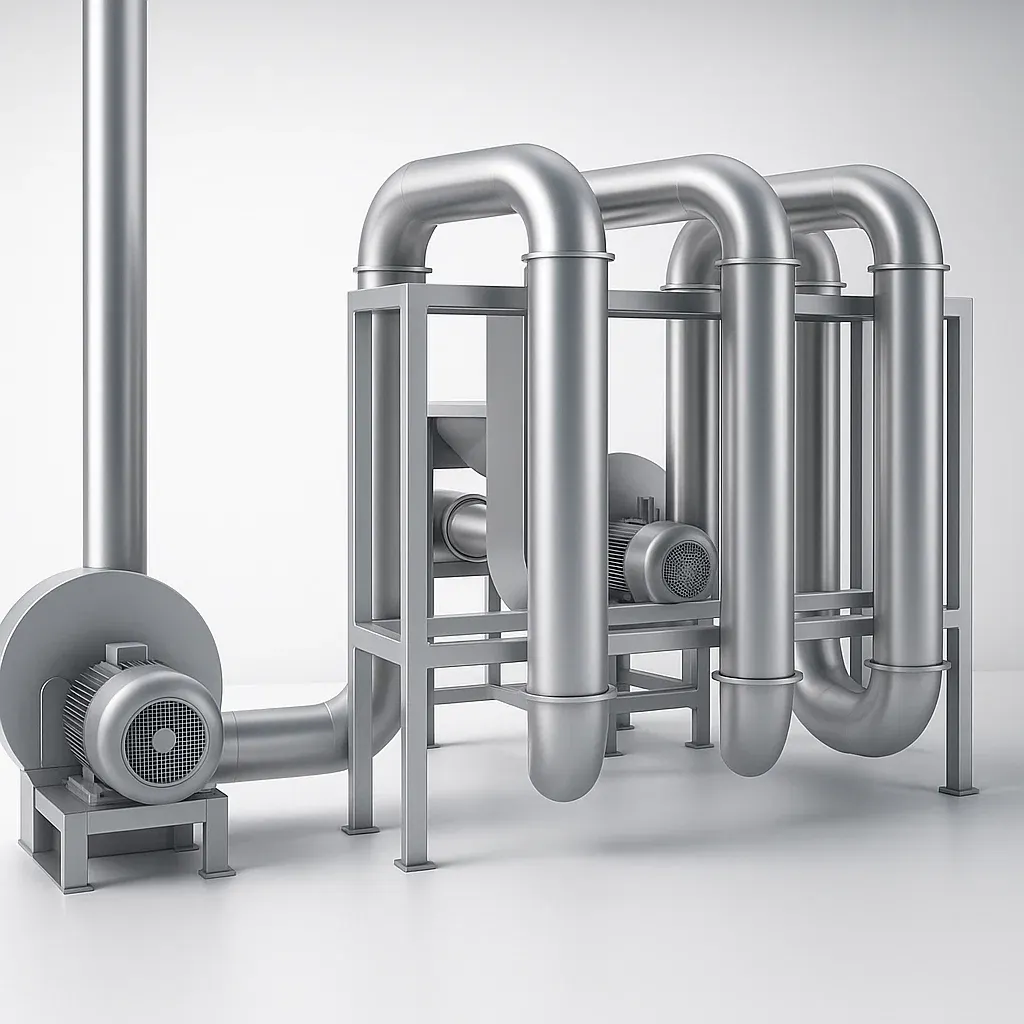

6. Dewatering & Thermal Drying

Funkcija: A two-stage process. A centrifugal dryer first mechanically removes most water, then a thermal pipe dryer uses hot air to reduce final moisture content to below 1%.

Technical Features: High-speed, dynamically balanced rotor, stainless steel piping, and precise temperature controls for an energy-efficient, perfectly dry final product.

Pogledajte naš sustav u akciji

Watch the complete transformation from post-consumer bottles to clean, high-quality flakes.

Unlock the Commercial Value of rPET

poliestersko spajano vlakno (PSF)

Used in textiles for clothing, carpets, and non-woven fabrics.

Recikliranje od boce do boce

Create new food-grade beverage bottles and containers.

PET trake za vezanje

Manufacture high-strength straps for industrial packaging.

PET Sheet & Film

Used for thermoforming packaging, trays, and containers.

What Our Clients Say

“Since installing this PET washing line, the quality of our flakes has improved dramatically, allowing us to sell them at a 15% premium. The system's stability and high degree of automation have exceeded our expectations.”

— David Chen, Director of Operations, Major Southeast Asian Recycler

“We are extremely satisfied with our production line. The team was professional from the initial consultation through final installation. Most importantly, their water circulation system has saved us a significant amount on utility costs.”

— Maria Garcia, Plant Manager, Plastics Manufacturer in Mexico

The Clear Advantage

| Značajka | Our PET Recycling System | Conventional / Budget Systems |

|---|---|---|

| Final Purity | <100 ppm (Food-grade achievable) | >500 ppm (High contamination, low value) |

| Washing Technology | Hot chemical wash + high-speed friction | Sólo lavado con agua fría |

| Razina automatizacije | Control PLC inteligente completo | Controles manuales, intensivo en mano de obra |

| Potrošnja vode | Bajo consumo con filtración y reciclaje de agua | Alto consumo con descarga constante |

| Vida útil de la máquina | Componentes de acero resistente al desgaste y acero inoxidable | Acero carbono estándar, propenso a la corrosión y óxido |

Tehničke specifikacije

Estándares de Calidad Final de Escamas

| Parametar | Valor Garantizado |

|---|---|

| Totalna nečistoća | <100 ppm |

| Sadržaj PVC-a | <50 ppm |

| Contenido de PP/PE | <20 ppm |

| Contenido metálico | <20 ppm |

| Sadržaj vlage | <1% |

| Tamaño de las escamas | 12-16mm (Personalizable) |

Modelos y configuraciones de línea de producción

| Kapacitet (kg/h) | Potencia instalada (kW) | Potrebna površina (m²) | Potrebno osoblje | Consumo de agua (m³/h) |

|---|---|---|---|---|

| 500 | 220 | 400 | 2-3 | 1 |

| 1000 | 500 | 750 | 3-4 | 3 |

| 2000 | 700 | 1000 | 4-5 | 5 |

| 3000 | 900 | 1500 | 5-6 | 6 |

| 6000 | 1200 | 2500 | 6-8 | 10 |

Često postavljana pitanja

Encuentre respuestas a preguntas comunes sobre nuestras líneas de reciclaje de PET.

¿Qué tipos de botellas de PET puede procesar esta línea?

Nuestras líneas pueden procesar una amplia variedad de botellas de PET post-consumidor, incluyendo las de refrescos, agua, aceite de cocina y limpiadores domésticos. Para materiales altamente contaminados como las botellas de aceite, podemos personalizar la línea con unidades de lavado previo y lavado químico mejorados.

¿Cuál es el tiempo de entrega para un sistema completo?

El tiempo de entrega depende de la capacidad de la línea y la personalización. Una línea estándar de 1,000 kg/h tiene un tiempo de fabricación de 60-90 días. Se proporcionará un cronograma preciso con su cotización oficial.

Nudite li instalaciju i obuku?

Sí, ofrecemos servicios de llave en mano completa. Nuestro equipo de ingeniería se desplazará a su sitio para manejar la instalación, puesta en marcha y pruebas de la línea. También proporcionamos capacitación integral para sus operadores y personal de mantenimiento para asegurar una operación suave y eficiente.

¿Cuál es su política de garantía?

Todo nuestro equipo viene con una garantía de un año que cubre defectos en la fabricación y materiales. Durante este período, proporcionamos piezas de repuesto gratuitas y servicio. Después del período de garantía, ofrecemos soporte técnico y piezas de repuesto a un precio competitivo.

¿Cuánto cuesta una máquina de reciclaje de botellas de PET?

El costo varía considerablemente según la capacidad, la configuración y el nivel de automatización. Una línea completa puede oscilar entre decenas de miles a varios cientos de miles de dólares. Para obtener una cotización precisa y competitiva, póngase en contacto con nuestros ingenieros de ventas con sus requisitos (materia prima, capacidad deseada y estándares de calidad de salida).

¿Listo para Actualizar Su Negocio de Reciclaje?

Contacte con nosotros hoy para obtener una propuesta técnica personalizada y una cotización detallada. Nuestros expertos responderán en un plazo de 24 horas para ayudarlo a convertir los residuos plásticos en un recurso valioso.