Overview

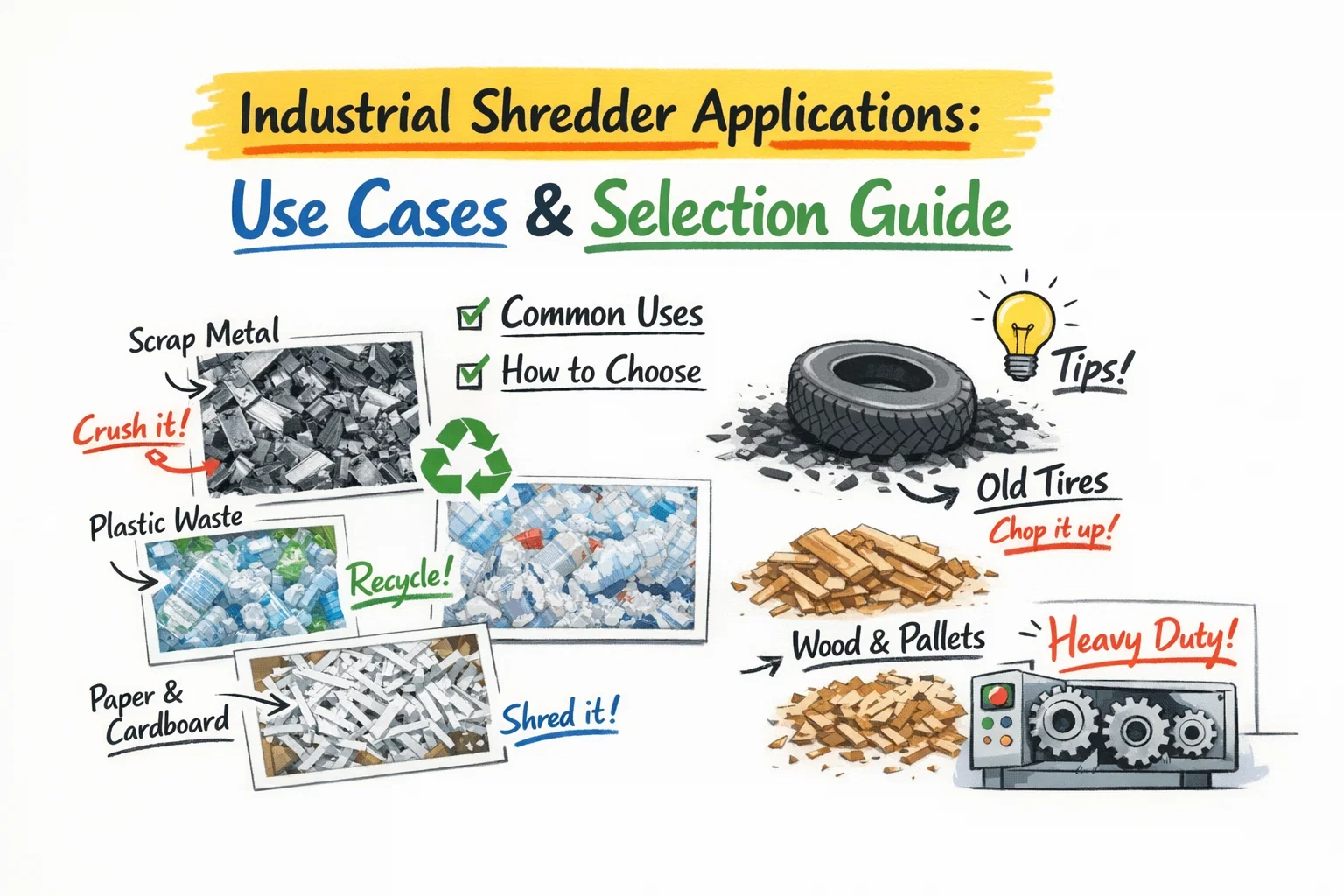

Industrial shredders and grinders are used for more than “waste reduction.” In practice, they are usually the first step in a material-handling line.

This page outlines common use cases, and what the shredder is expected to achieve in each.

Typical goals include:

- Secure destruction: make parts, prototypes, or branded products unrecognizable.

- Recycling prep: reduce size for sorting, washing, and reprocessing.

- RDF/SRF production: create a consistent fuel size for cement kilns or waste-to-energy.

- Volume reduction: lower storage and transportation costs.

Common equipment terms you may see in these applications:

- Single-shaft shredder (screened output, good for controlled particle size)

- Double-shaft shredder (high-torque, good for bulky/mixed waste)

- Granulator (also called crusher in some markets) (secondary size reduction for flakes/regrind)

Before selecting an application (what must be clarified)

To avoid vague “use case” descriptions, define these four items first. They determine machine type, configuration, and project feasibility.

- What waste is being processed?

- Material family: plastics (PET/HDPE/PP/PVC), rubber/tires, wood, paper/cardboard, textiles, e-waste, metals, mixed MSW, etc.

- Form: film, rigid, hollow, bales, purgings/lumps, pallets, drums, cables, etc.

- Contamination: dirt, sand, labels, metal, moisture, organic residues.

- Handling constraints: hazardous, confidential, bulky, abrasive, high-strength.

- Target particle size (output spec)?

- Rough reduction (e.g., 50–200 mm) vs. chips/flakes (10–50 mm) vs. fine regrind (≤10 mm).

- Uniformity requirement and tolerance.

- Screen size, cutter type, and downstream granulation often depend on this.

- What is the downstream product or process?

- Examples: RDF/SRF, plastic flakes for washing lines, regrind for extrusion/pelletizing, crumb rubber, WPC feedstock, insulation/fiber feed, engineered wood, secure-destruction residue.

- Whether washing, separation, drying, or densification will follow.

- What is the economic purpose?

- Cost reduction: disposal fees, internal reuse of scrap, compliance costs.

- Revenue: selling shredded material, producing value-added feedstock.

- Incentives: local recycling subsidies, tax credits, permitting benefits (varies by region).

- Key numbers to validate: throughput (kg/h), power cost, wear parts cost, labor, reject rate, sales price of output, payback period.

If you share the four items above (even approximate ranges), the application can be mapped to a practical shredding + separation flow and the machine spec becomes much more precise.

Prototype and model destruction

In manufacturing and engineering, product information can be sensitive.

Shredding is often used for secure destruction of:

- Prototypes

- Scale models and mockups

- Obsolete parts and assemblies

The goal is straightforward: make items unrecognizable and non-recoverable so they cannot be copied or reused.

In-house waste management

Many facilities run shredders to reduce disposal costs and improve recycling outcomes.

Common reasons include:

- Lower disposal fees through volume reduction and better sorting.

- Internal reuse of scrap as a secondary raw material.

- Cleaner site operations by standardizing waste handling.

Depending on local rules, organizations may also benefit from:

- Recycling-related subsidies or tax incentives

- Permitting advantages or compliance improvements

In some cases, shredded output becomes a saleable product.

For example:

- Shredded cardboard used as low-cost packing material

- Sorted plastic regrind sold to recyclers or compounders

Mixed-use developments / planned communities (onsite waste management)

In mixed-use developments and planned communities, waste is generated across residential, retail, and office areas.

Onsite shredding can support:

- A centralized recycling program for the whole site

- Lower hauling frequency through volume reduction

- Better material consistency for downstream sorting or recycling

Potential value paths include:

- Direct sale of shredded material (when quality and contamination are controlled)

- Internal reuse in approved applications (for example, some projects explore insulation or composite building materials)

Note: the feasibility depends heavily on the local collection model, contamination levels, and what downstream buyers accept.

Direct industrial applications

Many industries rely on shredding and grinding as part of production or recycling.

Examples include:

- Tire recycling: shredding tires into chips, then producing crumb rubber for asphalt, mats, and playground surfaces.

- Engineered wood: processing wood waste into feedstock for reconstituted panels.

- WPC (wood-plastic composites): shredding plastics and wood fiber for compounding.

- Plastic recycling: shredding rigid plastics (HDPE/PP/PET) into flakes for washing lines and reprocessing.

- Textiles and fibers: size reduction before separation and recycling.

Machine keywords often associated with these lines:

- Single-shaft shredder, double-shaft shredder

- Granulator, knife mill

- Magnetic separation (for tramp metal), screening

- Washing + drying (for plastic flakes)