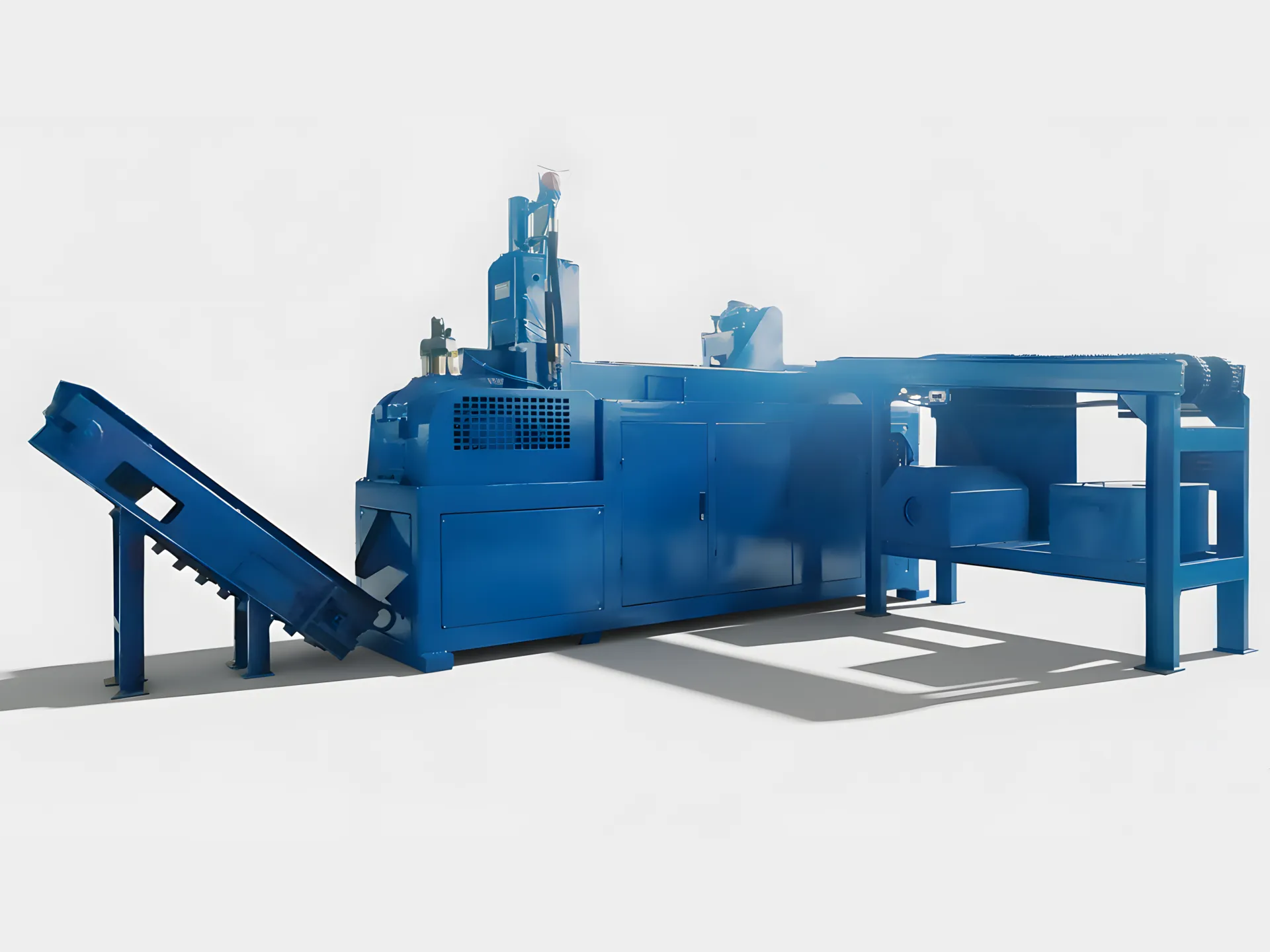

Lead Ingot Cold Cutting Machine

Revolutionize your lead granule production with our automated cold cutting technology. Eliminate hazardous fumes, reduce energy consumption, and increase efficiency compared to traditional melting processes.

A Safer, Smarter Way to Produce Lead Granules

Our PLC-controlled system is a strategic investment in environmental protection, operational efficiency, and workplace safety for the lead-acid battery industry.

Eliminates Harmful Fumes

By processing lead ingots in a cold state, our machine completely avoids the melting process, preventing the generation of hazardous lead fumes.

Significant Energy Savings

Dramatically reduces energy consumption and costs by eliminating the need for large-scale industrial melting furnaces.

Increased Production Efficiency

The fully automated system transforms standard lead ingots into ready-to-use granules with a high capacity of up to 2.75 tons per hour.

Fully Automated Control

The entire operation, from ingot conveying to granule discharge, is controlled by a reliable PLC system for consistent and unmanned operation.

From Solid Ingot to Granule: The Cold Process

Ingot Conveying

Standard lead ingots (45 kg) are automatically transported into the machine by the conveying mechanism.

Cold Extrusion

A powerful extrusion mechanism compresses the solid ingot multiple times to form uniform lead strips.

Granule Cutting

The lead strips are conveyed to the cutting mechanism, which precisely cuts them into consistently sized granules.

Granule Discharge

The final lead granules are discharged via a scraper conveyor, ready for the ball mill machine.

System Components

Technical Specifications

| Production Capacity | 2.5 - 2.75 Tons/hr |

|---|---|

| Input Material | Standard 45 kg lead ingots |

| Granule Size | From 25×25×17 mm down to 20 mm |

| Granule Weight | 75 - 100 g (± 15 g) |

| Total Installed Power | 28.8 kW |

| Actual Power Usage | ≤ 15 kW |

| Dimensions (Main Unit L×W×H) | 3028 × 1040 × 2100 mm |

| Total Machine Weight | Approx. 4 Tons |

| Required Water Pressure | 0.2 MPa |

| Required Air Pressure | 0.4 - 0.7 MPa |

Frequently Asked Questions

Why is "cold cutting" a better method than traditional melting?

Cold cutting offers three major advantages: 1) **Safety & Environment:** It completely eliminates the generation of toxic lead fumes, creating a much safer workplace and preventing environmental pollution. 2) **Energy Savings:** It consumes significantly less energy as it does not require large furnaces to melt the lead. 3) **Efficiency:** It's a faster, continuous, and fully automated process.

What is the purpose of the lead granules this machine produces?

The lead granules are the ideal feedstock for ball mill machines. In the lead-acid battery manufacturing process, these granules are ground into fine lead powder, which is a primary component in making the battery plates.

Can the size and weight of the granules be adjusted?

Yes, the machine allows for adjustments. The system can be configured to produce granules ranging from 25mm down to 20mm, with a corresponding weight range of approximately 75g to 100g, plus or minus a small tolerance.

Modernize Your Lead Granule Production

Contact our technical team to learn how the Lead Ingot Cold Cutting Machine can improve the safety, efficiency, and cost-effectiveness of your lead-acid battery manufacturing line.