Compact Desktop Shredder for Small‑Batch Plastic Regrind

Turn 3D printing scrap, bottle caps, and prepared PET bottles into 3–6 mm regrind for reuse and filament extrusion feedstock.

Check PriceInput Material Compatibility

Confirm polymer behavior, scrap geometry, and contamination level against the feed opening and knife set.

Selection starts with feedstock fit. Define your primary polymer family, scrap form, and the largest piece that must pass through the 120 × 200 mm opening without manual forcing. Rigid, clean scrap typically shears consistently and produces stable regrind. Films and elastic materials can bridge or wrap and may require pre‑cutting and controlled feeding. Contamination (sand, paper, metal) drives knife wear and maintenance frequency, so it should be declared up front for realistic service planning and trial criteria.

Rigid production scrap and rejects

Sprues, runners, thick‑wall parts, and rigid containers. Confirm maximum thickness and hardness for stable cutting load and edge life.

Thin films and sheet offcuts

PP/PE films and sheet trims. Specify thickness and pre‑cut length to reduce bridging/wrap and confirm stable discharge.

3D printing waste and prototyping scrap

Failed prints and offcuts (PLA/PETG/ABS). Confirm target regrind size and downstream handling (bin, hopper, or conveyance).

Mixed streams and elastic materials (trial required)

Mixed polymers, rubber, or contaminated scrap. Require a defined acceptance trial and a declared contamination limit.

Key Specifications

Key dimensions, knife options, and electrical configuration used for product comparison.

Use the data below to confirm basic fit: the feed opening for your scrap size, the drive system for cutting load, and the knife set options for your target regrind. If PET bottles are in scope, plan preparation (remove caps/labels, rinse, dry, and cut to fit the opening). Voltage can be customized; confirm your region’s mains and plug type during ordering to avoid delays.

| Feeding Port Dimensions | 120mm x 200mm |

| Target Regrind Output | 3–6 mm (application dependent) |

| Typical Throughput | 1–5 kg/h (material dependent) |

| Blade Model A | 22 rotating & 22 fixed blades (5mm width) |

| Blade Model B | 36 rotating & 36 fixed blades (3mm thickness) |

| Rotating Blade Diameter | 100mm |

| Blade Material | H13 High-Speed Industrial Steel |

| Motor Power | 1.5KW with Gearbox |

| Voltage | Customizable (110V/220V options) |

| Machine Weight | 101 kg |

| Overall Dimensions (L × W × H) | 650 × 300 × 780 mm |

Note: Specifications shown are for reference only. Contact us to confirm your configuration and request the complete specification sheet.

3–6 mm Regrind Output

Sized for consistent feeding into small extruders and controlled storage between steps.

For 3D filament extrusion and small‑batch reuse, regrind consistency matters more than maximum cutting speed. This unit is configured to produce a 3–6 mm output range (material dependent) that is easier to dry, store, and dose into a filament extruder hopper than mixed, oversized chunks. If you are targeting filament extrusion, plan a drying step and keep regrind sealed to prevent moisture pickup, especially for PETG and ABS. If your extruder requires a tighter size band, screening can be used after shredding.

Small‑Batch Throughput

Practical output for home and lab recycling workflows.

Typical throughput is 1–5 kg/h depending on polymer type, part thickness, and how consistently material is fed. Rigid, clean scrap usually processes faster than thin films or irregular shapes. For home use, the effective rate is often determined by preparation time (washing, drying, cutting bottles to fit the opening) and by how you collect and store regrind between steps.

If you are feeding a filament extruder, plan throughput around the full workflow, not the cutting step alone. Drying time, screening (if required), and keeping regrind segregated by polymer can determine how quickly you can produce usable feedstock for extrusion.

Blade Model Selection

Choose the knife set that best matches your regrind size target and material behavior.

Model A (5 mm) knife set

Wider knives with fewer cuts per revolution. Often preferred for tougher, thicker pieces and general regrind where maximum tolerance is the priority.

Model B (3 mm) knife set

Thinner knives with more cuts per revolution. Often preferred when you want more consistent, finer regrind for filament extruder feeding.

H13 tool‑steel knives

Built for impact resistance and wear control under repeated cutting. Edge life depends heavily on abrasives and contamination.

Forward/reverse clearing

Helps recover from bridging or wrap events without disassembly and supports stable day‑to‑day operation.

Collection and Storage

Keep regrind clean, dry, and easy to feed into a filament extruder.

For personal recycling workflows, regrind handling is a major success factor. Define how you will collect output (bin, bucket, or bag), how you will keep it dry, and how you will transfer it into a filament extruder or storage container without spilling fines. If you recycle multiple plastics, label containers and avoid mixing polymers unless your downstream process is designed for it.

1. Prepare and load

Rinse and dry bottles, remove labels/caps as needed, and cut pieces to fit the feed opening. Keep metal and grit out of the cutting chamber.

2. Shred and clear

The knife set and geared drive produce regrind. Forward/reverse helps recover from bridging or wrap without disassembly.

3. Collect and store

Collect regrind in a sealed container. Dry if needed and store by polymer type before feeding an extruder.

Operation and Safety

Simple controls, safe handling, and predictable clearing during home and lab use.

Use stable placement and keep hands/tools away from the feed opening during operation. Forward/reverse control is provided to clear jams caused by film wrap or irregular shapes. For best results and lower wear, keep metal, stones, and abrasive dirt out of the feed. If your setup generates fine dust, use closed collection and clean around the discharge area regularly.

Knife service is driven by results: when regrind quality drops or cutting becomes noticeably harder, plan cleaning and sharpening/replacement. Keeping one spare knife set minimizes downtime for active hobby or lab workflows.

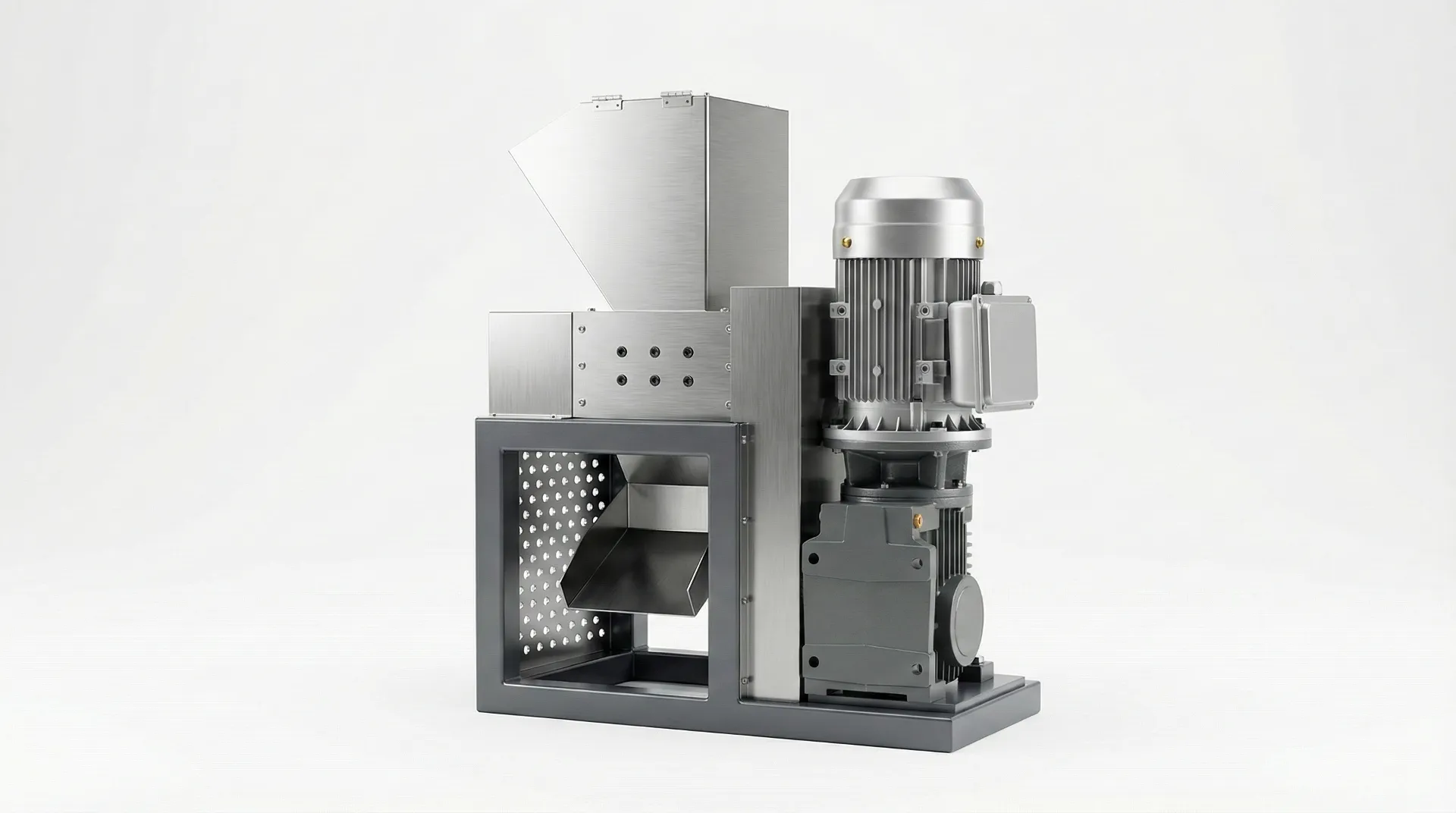

Photos and Demo Video

See the blade set, controls, and a short run demo.

The images show the knife assembly and the control layout used for forward/reverse clearing. The demo video provides a quick reference for feeding behavior and discharge consistency. For filament extrusion workflows, focus on whether the output looks uniform, whether it generates excessive fines, and whether collection into a bin/bag is clean and controlled.

If your main feedstock is 3D prints, bottle caps, or PET bottle flakes, request a sample run on a similar material and ask for the resulting regrind photo next to a ruler or screen. This helps confirm whether the output will feed your extruder hopper and whether additional screening is needed.

Pricing and Availability

Check price, voltage option, and knife model for your recycling workflow.

To confirm the right configuration and pricing, share what you plan to recycle (PLA/PETG/ABS prints, bottle caps, PET bottles), your target output size (3–6 mm), and your preferred knife model (5 mm or 3 mm). Voltage is customizable; include your country/region so we can recommend the correct option.

Include the details below for the fastest response:

- Materials: PLA/PETG/ABS, caps (HDPE/PP), or PET bottle flakes.

- Largest piece size you want to feed (after cutting bottles).

- Knife model preference: 5 mm (general) or 3 mm (finer feeding).

- Voltage option required: 110V or 220V (customizable).

- City/country for shipping estimate and lead time.