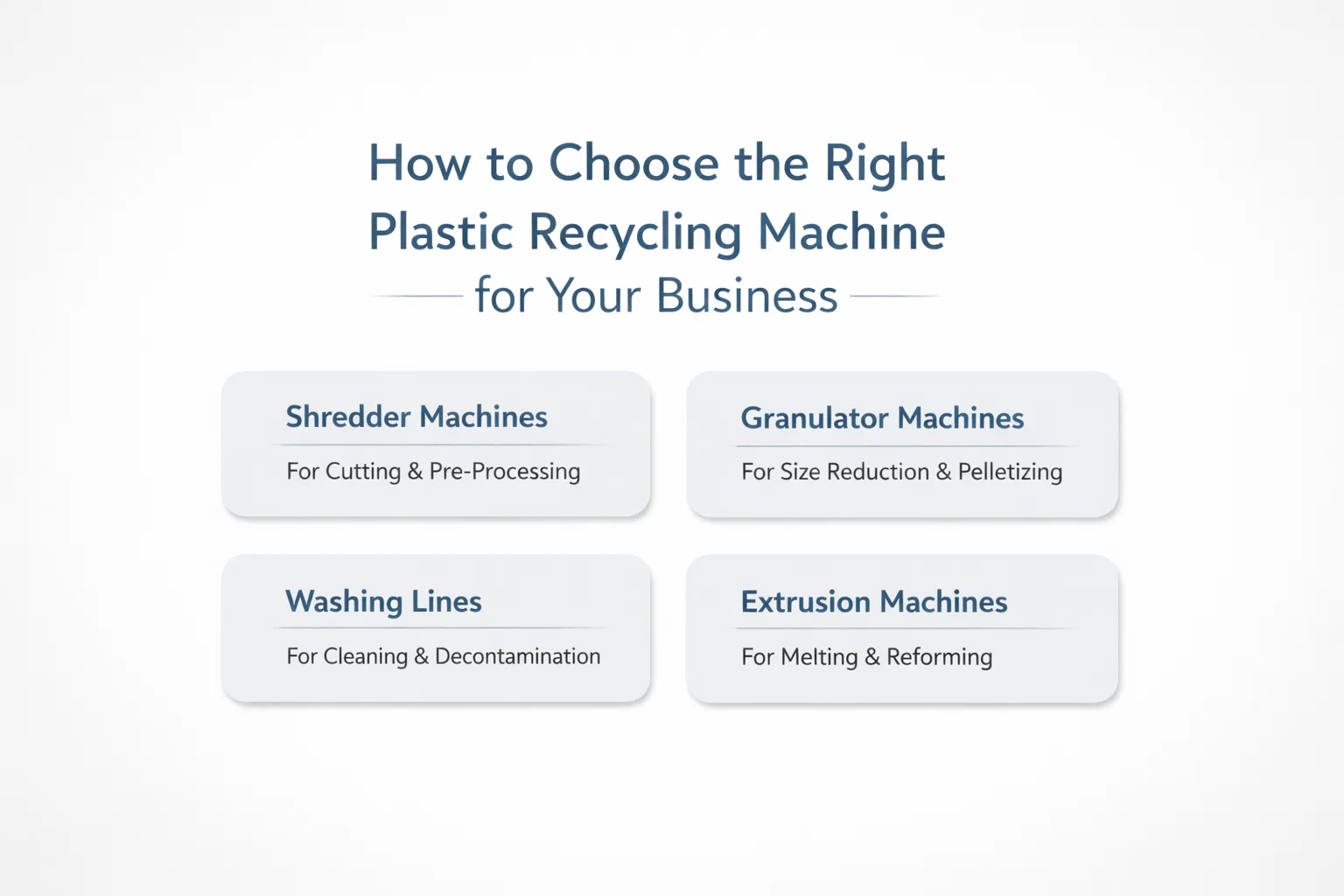

How to Choose the Right Plastic Recycling Machine for Your Business

Finding the right plastic recycling machine requires more than just comparing specifications; it demands a strategic look at your material sources and production goals. As we navigate the industrial landscape of 2026, efficient waste processing is essential for profitability. Whether you are processing post-consumer bottles or factory floor scraps, the equipment you select will directly impact your operational success. While the plastic recycling machine price is often the first number buyers look at, the true value lies in how well the technology matches your specific waste stream.

This guide examines the critical factors you must evaluate to build a successful recycling line, ensuring you get the best return on your investment.

1. Assess Your Material Type and Condition

Before contacting manufacturers, you need a clear profile of your input material. Plastic recycling machines function differently based on the density, moisture level, and form of the plastic. Choosing the wrong feeding or cutting mechanism is the most common reason for production bottlenecks.

Rigid vs. Flexible Plastics

The physical form of your waste dictates the preprocessing requirements:

- Flexible Plastics (LDPE Films, LLDPE, PP Woven Bags): These materials are light and occupy high volume. Standard hoppers often bridge or clog. You need a machine with an integrated cutter-compactor system. This component densifies the material using friction heat before feeding it into the extruder, ensuring a stable output rate.

- Rigid Plastics (HDPE Bottles, PP Pipes, ABS Crates): These require heavy-duty size reduction. A powerful plastic shredder is typically the first step to break down bulky items. Following this, a plastic granulator refines the material into uniform flakes, which are then ready for extrusion.

Clean vs. Contaminated Waste

Post-consumer waste often carries dirt, oil, paper labels, and moisture. If you process washed flakes, your extruder must have a specialized degassing system (venting) to remove steam and volatiles. Running wet material through a standard machine will result in bubbles and weak pellets. For heavily printed films, look for double-venting systems that ensure high-quality, reusable pellets.

2. Evaluating Throughput and Capacity

Capacity requirements drive both the physical footprint of the line and the final plastic recycling machine price. Manufacturers usually rate machines in kilograms per hour (kg/hr).

Be realistic about your volume. Buying a machine that is too small limits your growth, while an oversized machine wastes energy and floor space. A good rule is to select a system that handles your current peak volume with a 20-30% margin for future expansion.

Looking for High-Efficiency Equipment?

Explore our range of advanced recycling systems designed for both rigid and flexible plastics. Get precise specs, custom configurations, and pricing details.

View Machine Models3. Understanding the Plastic Recycling Machine Price

The cost of recycling equipment varies significantly based on component quality and automation levels. While a lower upfront cost looks attractive, it often hides higher operating expenses down the line.

Key Price Influencers:

- Component Quality: Machines using generic motors and gearboxes are cheaper but prone to failure. Premium models use recognized brands (like Siemens or ABB) and bimetallic screws that resist wear, justifying a higher price tag through longevity.

- Automation: Fully automated lines with smart control panels reduce labor costs but increase the initial investment.

- Filtration Technology: Advanced laser or backflush filters allow you to process dirtier material without constant stops for screen changes, significantly boosting productivity.

For a broader perspective on industry standards and recycling definitions, the Association of Plastic Recyclers (APR) offers excellent technical resources.

4. Energy Efficiency and Operational Costs

In 2026, energy costs remain a major line item for any recycling plant. Modern plastic recycling machines utilize Variable Frequency Drives (VFDs) and infrared heating elements to minimize power consumption. When comparing quotes, ask for the specific energy consumption per kilogram of output. A machine that saves 15% on electricity bills will pay for its higher sticker price within a few years of operation.

5. After-Sales Support and Spare Parts

Even the best heavy machinery requires maintenance. The availability of spare parts and technical support is as important as the machine itself. Ensure your supplier offers:

- Quick dispatch of consumable parts (blades, screens, heaters).

- Remote troubleshooting capabilities via internet connectivity.

- Comprehensive operator training to prevent mishandling.

Final Thoughts

Selecting the right equipment is a balance between your material needs, production goals, and budget. By focusing on the total cost of ownership rather than just the initial plastic recycling machine price, you secure a reliable asset that drives your business forward. At Energycle, we help you navigate these choices to find the perfect fit for your facility.

Frequently Asked Questions

A single-screw extruder is standard for recycling clean, pre-crushed materials like PE film flakes. A twin-screw extruder offers better mixing and compounding capabilities, making it ideal for adding fillers, masterbatches, or modifying material properties.

Handling moisture requires specific components like vacuum degassing systems and stronger vacuum pumps. These additions increase the machine’s complexity and price but are essential for processing washed or post-consumer waste to prevent defects in the final pellets.

Generally, no. Different plastics have different melting points and flow characteristics. While some machines can handle compatible groups (like PE and PP), processing incompatible materials (like PVC and PET) on the same line usually causes contamination and equipment damage.