In the competitive world of plastic and waste recycling, downtime is the enemy of profitability. When procurement officers and plant managers search for industrial shredders, they are often bombarded with specification sheets that look remarkably similar. Two machines might claim the same motor power, the same chamber size, and the same theoretical throughput. Yet, one machine runs flawlessly for a decade, while the other suffers from cracked frames, bearing failures, and constant vibration within six months.

The difference lies not in the spec sheet, but in the engineering details: the quality of the raw materials, the precision of the machining, and the integrity of the welding.

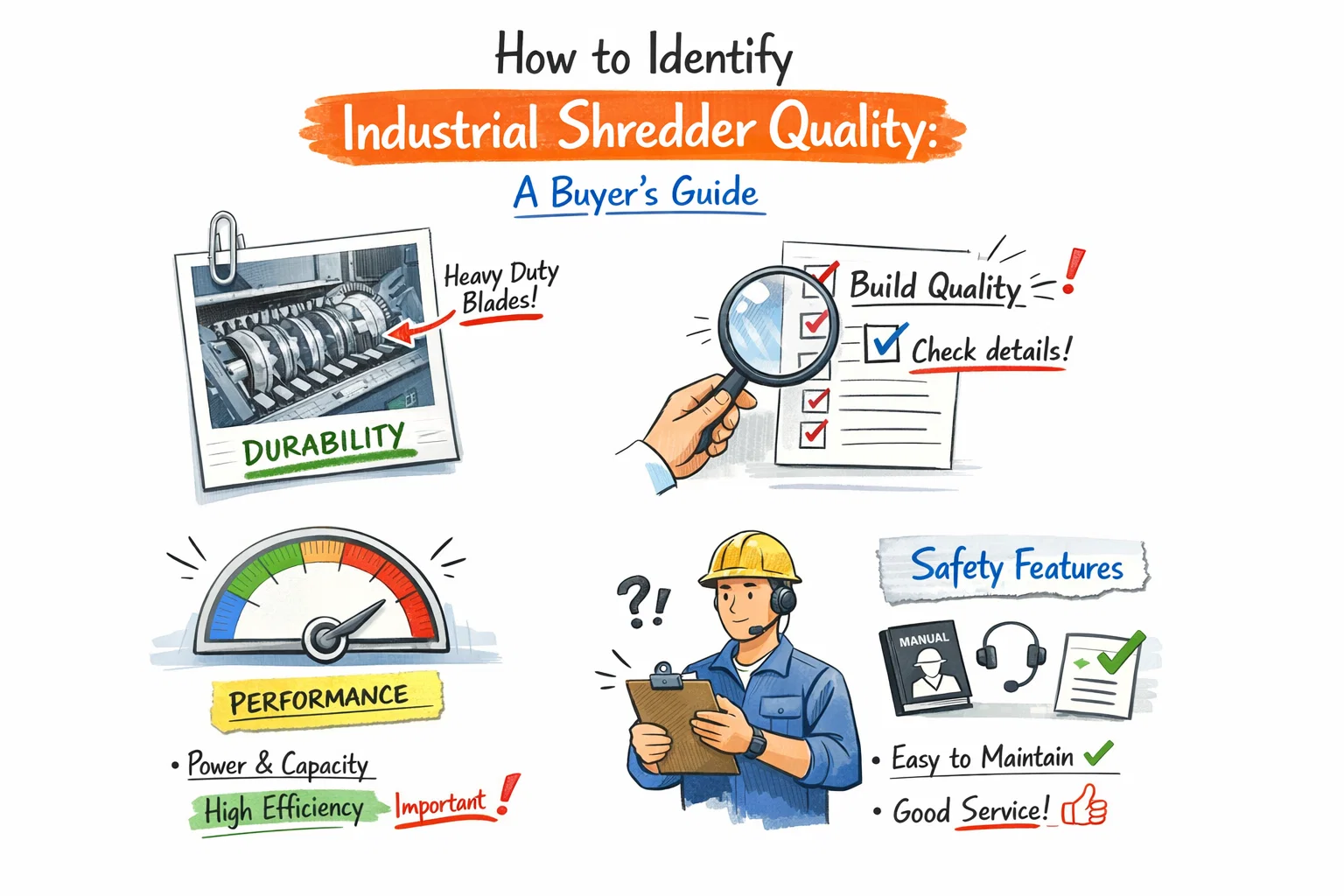

As an experienced consultant in industrial machinery, I have inspected hundreds of machines. This guide will walk you through exactly how to judge shredder quality by looking beneath the surface paint, ensuring you invest in equipment that delivers long-term ROI.

1. Material Selection: The Backbone of Durability

The longevity of a shredder begins with the steel used to build it. A recycling machine faces immense torque, shock loads, and abrasive friction. If the base material is weak, no amount of engineering can save it.

The Machine Body and Hopper

Low-cost manufacturers often use standard A3 (Q235) carbon steel for the entire machine structure to cut costs. While acceptable for light framing, this is insufficient for the high-stress environment of heavy-duty shredding.

High-quality manufacturers utilize Q345 (High-Strength Low-Alloy Steel) or higher grades for the main chassis and hopper. This steel offers significantly better tensile strength and impact resistance. When inspecting a machine, ask about the steel grade. Furthermore, check the thickness. A heavy-duty shredder body material should feel substantial. Thin hopper walls will warp over time, leading to gaps where material can jam.

The Rotor and Shaft

The rotor is the heart of the shredder. It must withstand the immediate impact of solid plastics, wood, or textiles. Superior shafts are forged and heat-treated to modify the crystalline structure of the metal, balancing hardness with flexibility. If a shaft is too brittle, it snaps; too soft, and it twists.

Wear Components

For blades and bed knives, standard tool steel is the bare minimum. Premium machines utilize materials like D2, SKD11, or imported Hardox steel. These materials retain their edge longer, reducing the frequency of maintenance shutdowns.

2. Welding Craftsmanship: Ensuring Structural Integrity

In heavy machinery, a weld is often the primary stress point. Poor welding leads to structural fatigue and catastrophic frame failure. You do not need to be a certified welder to spot the difference between a rushed job and professional craftsmanship.

Visual Inspection of Welds

Look closely at the joints on the machine frame and the hopper.

- Good Welding: You should see a consistent “fish-scale” pattern. The bead should be uniform in width and height, indicating a steady hand or robotic welding process.

- Bad Welding: Look for porosity (tiny holes in the weld), spatter (droplets of metal stuck around the weld), or undercutting (where the base metal is melted away near the weld toe).

Full Welding vs. Stitch Welding

To save time and gas, budget manufacturers often “stitch weld” or spot weld non-critical areas. However, in a vibrating shredder, every joint matters. A sturdy and durable body structure requires full, continuous welding throughout the frame to distribute vibration energy evenly.

Annealing (Stress Relief)

This is the invisible “secret sauce” of high-end manufacturing. When steel is welded, extreme heat creates internal stresses. If these stresses are not relieved, the frame will warp as it cools or during operation, throwing the shaft out of alignment.

Top-tier manufacturers place the entire welded frame into a large annealing furnace to heat-treat the structure before machining. This stabilizes the metal. If a supplier cannot confirm they perform post-weld stress relief, consider it a red flag.

3. Machining Precision: The Key to Smooth Operation

Once the frame is welded and annealed, it must be machined. This is where the geometric accuracy of the shredder is determined.

Concentricity and Alignment

The bearing seats on either side of the shredder box must be perfectly aligned. If they are off by even a fraction of a millimeter, the shaft will struggle to turn, creating friction and heat. This dramatically shortens the life of the bearings and the motor.

Ask the manufacturer about their processing equipment. Do they use large-scale CNC Gantry Milling Centers to machine the entire frame in one setup? Or do they use manual boring tools? CNC machining ensures that the bearing housing surfaces are parallel and the rotor axis is perfectly centered.

Assembly Tolerances

Check the gap between the rotor blades and the fixed counter-knives. A smaller, consistent gap (adjusted based on the material being shredded) indicates a rigid, well-machined frame. If the gap varies across the width of the rotor, the frame is likely twisted or poorly machined.

4. Component Quality: Bearings, Motors, and Hydraulics

A machine is only as strong as its weakest component. Manufacturers can build a great frame but fail by installing sub-par electrical or mechanical parts.

Bearings and Seals

The bearings take the brunt of the workload. When asking industrial shredder bearing brands, you should look for names like SKF, FAG, NSK, or Timken. These top-tier brands use higher-quality steel and stricter tolerances than generic alternatives.

Equally important is the sealing system. Shredding plastic and textiles creates fine dust. If dust enters the bearing housing, it acts like sandpaper. Look for labyrinth seals or external bearing housings that separate the bearing from the cutting chamber.

Układy hydrauliczne

For shredders with a hydraulic ram (pusher), the hydraulic station must be reliable. Leaks are a fire hazard and a maintenance headache. Check for high-quality hoses and fittings. The hydraulic ram movement should be smooth and consistent, not jerky.

5. Case Study: Selecting a Machine for Challenging Materials

Different materials require different engineering focuses. For example, rigid plastics require impact strength, while textiles and carpets require high torque and tight cutting gaps to prevent wrapping.

If your facility handles post-consumer waste, specifically carpets or woven sacks, you face a unique challenge. These materials are tough and abrasive. When considering how to choose a durable carpet shredder, you need a machine with specific features:

- Konstrukcja zapobiegająca nawijaniu: The rotor must be designed to prevent long fibers from wrapping around the shaft and burning out the seal.

- High Torque Gearbox: Carpets are dense. Direct drive systems may stall; a reducer-driven system provides the necessary torque.

- Robust Blade Mounting: The bolt mechanism holding the blades must be secure against the constant tugging of fabric.

For these demanding applications, we recommend investigating a high-quality single shaft shredder. This type of equipment is specifically engineered to handle the high-tensile resistance of textile waste without jamming, ensuring your processing line maintains high throughput.

6. The Energycle Commitment

At Energycle, we understand that a recycling machine is an investment in your company’s future. We do not cut corners on the “Three Pillars of Quality”:

- Przybory: We strictly use high-grade, heavy-gauge steel for our frames and premium wear-resistant alloys for our cutting tools.

- Welding: Our certified welders utilize full-penetration welding techniques, followed by rigorous stress-relief heat treatment to ensure the frame never warps.

- Machining: We utilize advanced CNC machining centers to ensure every bearing seat and bolt hole is precise to the micron.

When you check equipment craft details on an Energycle machine, you will see the difference. From the clean welds to the branded components (Siemens, SKF, Schneider), every element is chosen for reliability.

Wniosek

Distinguishing between a premium industrial shredder and a budget alternative requires looking beyond the brochure. By evaluating the steel grade, inspecting the welding consistency, and verifying the machining precision, you can predict the machine’s reliability.

Don’t let equipment failure dictate your production schedule. Choose a partner that prioritizes engineering integrity.

Ready to upgrade your recycling facility with equipment built to last?

Skontaktuj się z Energycle już dziś for a consultation or Poproś o wycenę for our heavy-duty shredding solutions. Let us help you build a more efficient, profitable recycling line.