Plastic granulators are a critical part of daily operations in recycling plants, responsible for reducing plastic waste into uniform granules for downstream processing. Over time, however, wear, contamination, and improper operation can significantly reduce performance and increase downtime.

This guide focuses on practical maintenance, troubleshooting, and operational best practices to help recycling facilities extend service life, maintain stable output, and reduce unplanned shutdowns—without overlapping with equipment selection or purchasing decisions.

Why Proper Granulator Maintenance Matters in Recycling Plants

In continuous recycling operations, a plastic granulator is exposed to variable materials, abrasive contaminants, and high mechanical loads. Without a structured maintenance routine, even well-designed machines can suffer from premature wear and declining performance.

Effective maintenance helps to:

- Maintain consistent granule quality during long production runs

- Reduce unexpected stoppages and emergency repairs

- Extend the operational lifespan of wear components

- Improve overall plant efficiency and safety

For recycling facilities operating on tight margins, preventive maintenance is often more cost-effective than reactive repairs.

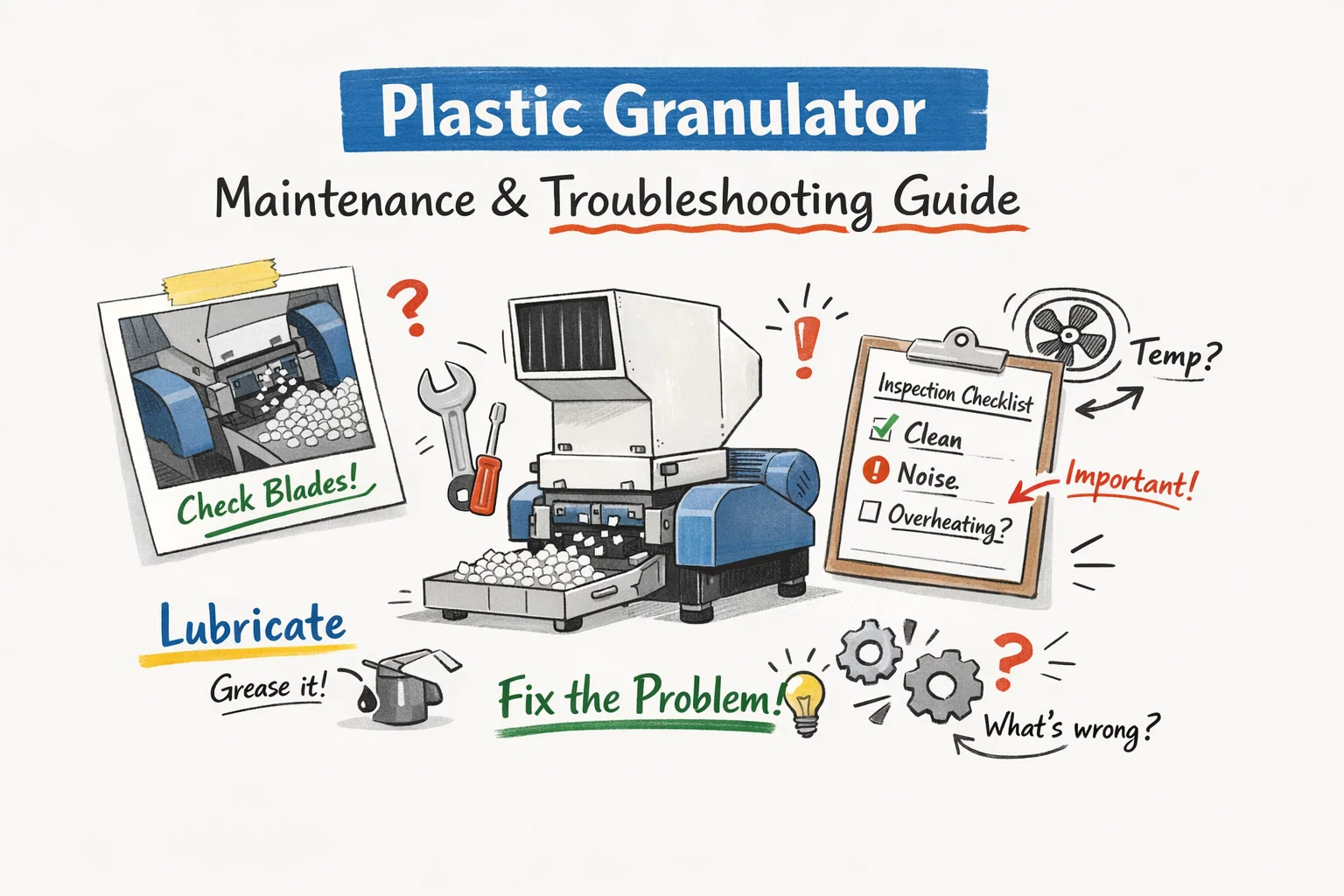

Essential Plastic Granulator Maintenance Tasks

A structured maintenance schedule ensures stable operation under real recycling conditions. The following tasks are recommended for most industrial recycling environments.

Daily Maintenance

- Clean the hopper and feeding area to prevent material buildup

- Inspect the cutting chamber for residual plastic or contamination

- Check blades and screens for early signs of wear

- Verify lubrication points according to operating hours and load

Weekly Maintenance

- Clean air filters to maintain proper cooling and airflow

- Inspect drive belts and couplings for tension and alignment

- Check electrical connections for looseness or overheating

- Remove dust accumulation from external surfaces

Monthly Maintenance

- Verify rotor and stator alignment under operating conditions

- Inspect bearings for abnormal noise or temperature rise

- Clean and lubricate the gearbox if applicable

- Test safety systems such as emergency stops and interlocks

Annual or Scheduled Overhaul

- Replace high-wear components such as blades, screens, and bearings

- Inspect structural elements for fatigue or cracking

- Recheck machine calibration to restore cutting efficiency

- Review operating logs to identify recurring issues

Troubleshooting Common Plastic Granulator Problems

Even with regular maintenance, operational issues may still occur. Early diagnosis can prevent minor problems from escalating.

Granulator Will Not Start

- Confirm stable power supply and correct voltage

- Inspect safety switches and interlocks

- Ensure the emergency stop circuit is fully reset

Reduced Output or Throughput

- Check blade sharpness and cutting gap

- Inspect screens for clogging or deformation

- Verify that feed material size and flow rate are consistent

Inconsistent Granule Size

- Inspect blades and screens for uneven wear

- Confirm proper rotor-to-stator alignment

- Evaluate input material consistency and contamination levels

Excessive Noise or Vibration

- Inspect bearings and mounting points

- Check for rotor imbalance caused by uneven wear

- Ensure the machine is correctly leveled and anchored

Operational Best Practices to Improve Granulator Performance

Beyond routine maintenance, operational discipline plays a major role in long-term performance.

Use Application-Appropriate Blades and Screens

Selecting cutting components that match material type, thickness, and hardness reduces energy consumption and wear.

Maintain a Stable Feeding Process

Sudden surges or inconsistent feeding increase mechanical stress and accelerate blade degradation.

Monitor Energy Consumption Trends

A gradual increase in power draw often indicates blade wear, screen blockage, or bearing issues before visible symptoms appear.

Apply Predictive Maintenance Where Possible

Condition monitoring, vibration analysis, and temperature tracking help identify failures early and reduce unplanned downtime.

When Maintenance Alone Is No Longer Sufficient

Maintenance can extend service life, but it cannot compensate indefinitely for capacity limitations, structural fatigue, or changing production requirements.

If a recycling plant experiences:

- Persistent throughput decline

- Increasing vibration despite repeated repairs

- Structural wear affecting safety or reliability

it may be time to evaluate equipment replacement or system upgrades.

For facilities assessing new solutions, you can review our industrial plastic granulator options here:

(Single reference for evaluation purposes; maintenance guidance remains equipment-agnostic.)

Conclusion

Plastic granulator maintenance is not simply a checklist—it is an operational strategy that directly affects productivity, safety, and cost control in recycling plants. By combining preventive maintenance, structured troubleshooting, and disciplined operation, recyclers can achieve more reliable performance and longer equipment life.

A clear separation between operational guidance and equipment selection ensures better decision-making at every stage of the recycling process.

Frequently Asked Questions (FAQ)

How often should granulator blades be serviced?

Service intervals depend on material abrasiveness, contamination level, and operating hours. In industrial recycling environments, inspection every 100–300 hours is common.

Are aftermarket parts suitable for recycling operations?

While aftermarket parts may reduce short-term cost, compatibility and durability can vary. Inconsistent parts often lead to faster wear and unstable operation.

How should operators be trained for daily maintenance?

Operators should follow a documented checklist covering cleaning, inspection, and safety verification. Practical training and supervision are essential for consistency.

What should be done in case of sudden failure?

Shut down the machine safely, isolate power, and diagnose the issue systematically. Repeated failures usually indicate deeper mechanical or operational issues.