Recycling News

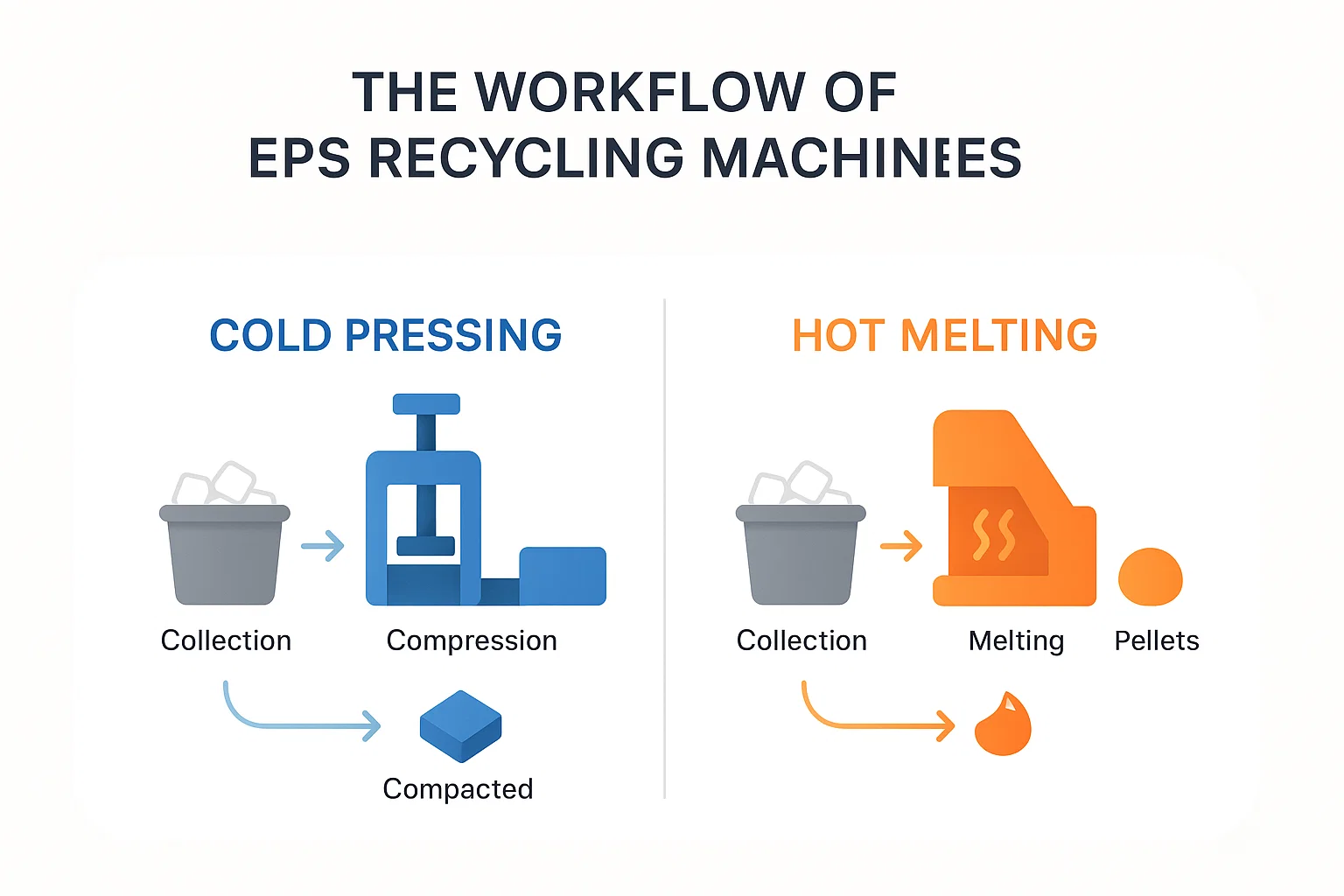

In the ever-evolving world of industrial recycling, understanding the core principles behind machinery is crucial for selecting the right equipment for your operations. One such piece of equipment is the EPS Cold Press Machine – a vital tool for efficiently recycling expanded polystyrene (EPS) foam. EPS is widely used in packaging and construction, but its disposal poses significant environmental challenges due to its lightweight and bulky nature. The EPS Cold Press Machine provides a sustainable solution by compacting and recycling this material into a more manageable form.

This article offers a detailed explanation of how the EPS Cold Press Machine works, exploring its features, applications, and the benefits it offers to industrial recycling operations.

What is an EPS Cold Press Machine?

An EPS Cold Press Machine is a piece of recycling machinery specifically designed to compress and recycle EPS foam waste. It uses a mechanical pressing process that operates without the need for heat, making it more energy-efficient and environmentally friendly compared to other methods. The process helps to reduce the volume of EPS foam waste, turning it into a compact form that can either be reused in manufacturing or further processed into other products.

Key Features:

- Cold Press Technology: Utilises pressure instead of heat to compress EPS foam.

- Energy Efficient: Consumes less energy compared to thermal methods.

- Compact and Robust: Efficiently handles large volumes of EPS waste.

For more information on how these machines can streamline your EPS recycling process, visit our EPS Foam Cold Press Machine page.

The Working Principle of the EPS Cold Press Machine

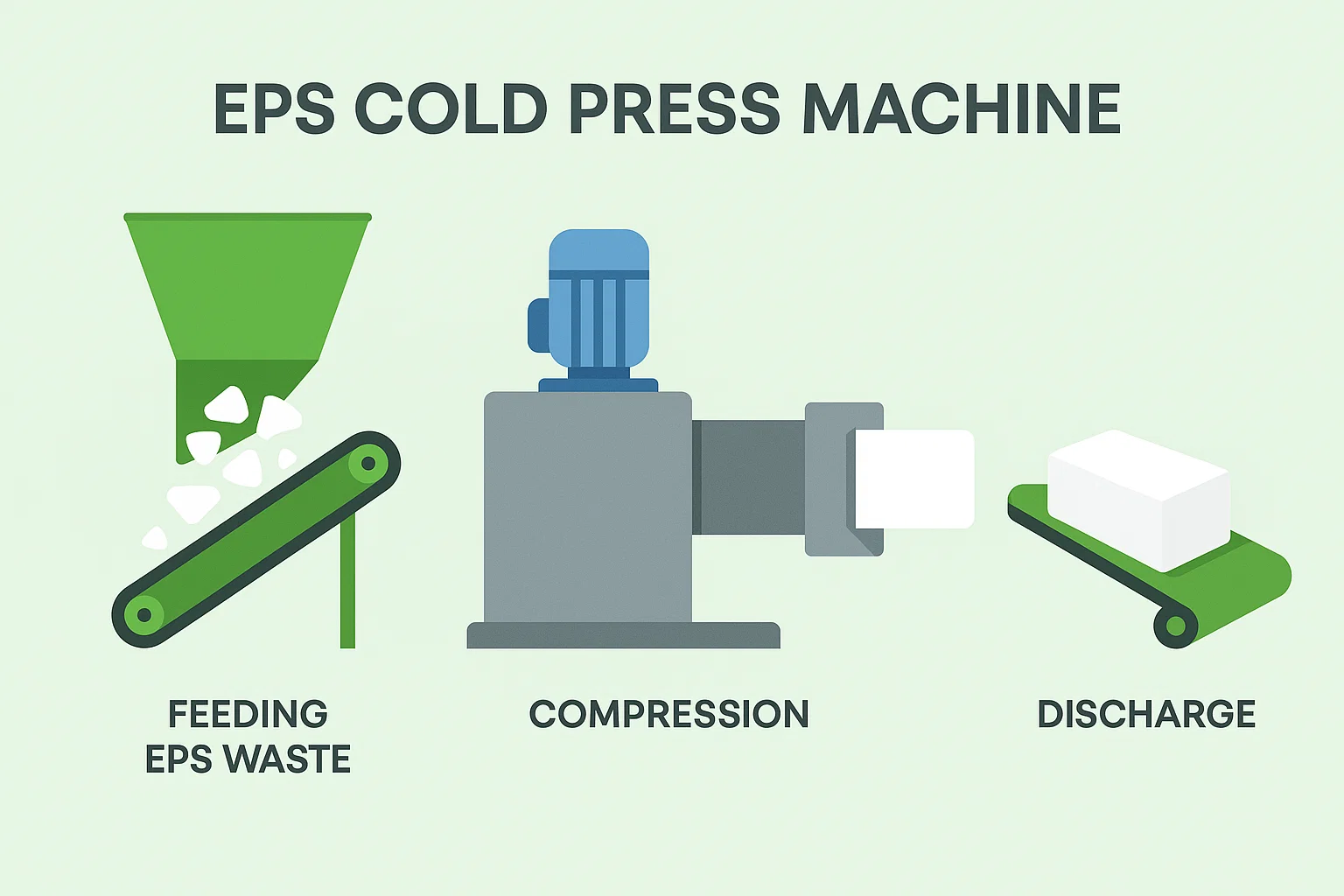

The working principle of an EPS Cold Press Machine is rooted in its simple yet effective operation. Let's break it down into key stages to understand the process more clearly:

1. Feeding the EPS Foam Waste

The process begins with feeding the EPS foam waste into the machine. This can include a wide range of EPS products, such as packaging material, insulation, and construction waste. The foam is typically broken down into smaller pieces or chunks to fit into the machine’s hopper.

2. Compression Process

Once the foam is loaded into the hopper, it moves into the press chamber, where the main action takes place. The EPS foam is subjected to high pressure through a mechanical pressing system. During this stage, the foam is compacted, and the air within the material is squeezed out, significantly reducing its volume.

The machine's hydraulic system ensures that the pressure applied is consistent and can be adjusted depending on the specific requirements of the foam type and volume.

3. Shaping and Forming

After compression, the EPS material is often shaped into compact blocks or bales. These blocks are easier to handle, store, and transport, making them much more efficient for recycling and reuse. The compacted blocks also have reduced surface area, which makes them more environmentally friendly when disposed of or processed further.

4. Discharge

Once the EPS foam has been compacted into blocks or bales, it is discharged from the machine. These compressed forms of EPS are then ready for further processing, such as being used in the production of new products or sent for more advanced recycling techniques.

Benefits of Using EPS Cold Press Machines

The EPS Cold Press Machine offers a variety of benefits, making it a valuable tool for industries looking to manage EPS waste efficiently:

- Environmental Impact: By recycling EPS foam, the machine helps reduce the waste that often ends up in landfills. The cold pressing process is also more environmentally friendly, using less energy than thermal methods.

- Cost-Effective: EPS waste can accumulate quickly in industries such as packaging and construction. By compressing the foam, businesses can reduce the space needed for storage, leading to cost savings in waste management.

- Improved Recycling Efficiency: EPS foam, when compacted, can be more easily processed and reused in manufacturing, closing the loop on waste and encouraging sustainability.

- Minimal Maintenance: The cold pressing process reduces wear and tear on machinery compared to heat-based methods, leading to lower maintenance costs.

Applications of EPS Cold Press Machines

EPS Cold Press Machines are highly versatile and can be used in various industries that deal with large volumes of EPS waste. Some of the primary applications include:

- Packaging Industry: EPS is commonly used in packaging materials, particularly for fragile goods. The cold press machine helps compress discarded packaging materials for easier recycling.

- Construction Industry: EPS is used as an insulation material in the construction sector. The cold press machine enables efficient recycling of scrap insulation material.

- Electronics: Many electronic products are packaged with EPS foam to prevent damage during shipping. Recycling this foam with a cold press machine reduces waste and promotes circularity in the supply chain.

Key Considerations When Selecting an EPS Cold Press Machine

When purchasing an EPS Cold Press Machine for your operations, several factors should be considered to ensure you choose the right model for your needs:

- Machine Capacity: Ensure the machine can handle the volume of EPS waste your facility generates.

- Energy Consumption: Opt for machines that offer high efficiency and low energy consumption to reduce operational costs.

- Durability and Maintenance: Look for robust machines that require minimal maintenance and are built to last under heavy-duty conditions.

- Ease of Operation: Choose a machine with user-friendly controls and minimal operational complexity to enhance productivity.

Conclusion

The EPS Cold Press Machine is a valuable asset in the industrial recycling landscape, offering an efficient and environmentally friendly solution to EPS foam waste. By understanding its working principle, features, and benefits, you can make an informed decision when selecting recycling machinery for your operations.

Energycle provides high-quality EPS Cold Press Machines, designed to streamline your recycling processes while offering excellent performance and energy efficiency. If you're looking to reduce waste, improve sustainability, and save on operational costs, this machine could be the perfect fit for your business.

For more information on our EPS Cold Press Machines, visit Energycle EPS Foam Cold Press Machine.

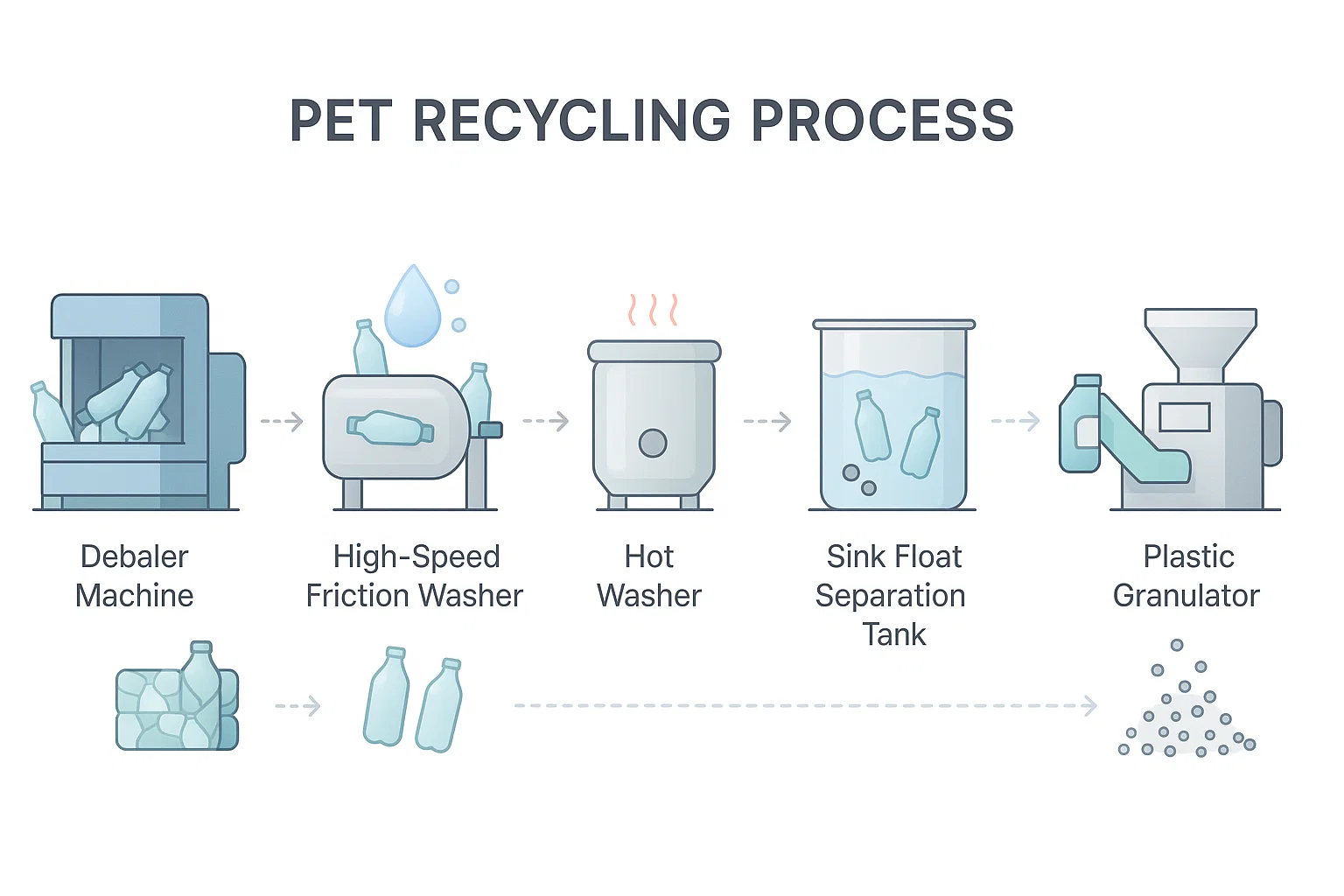

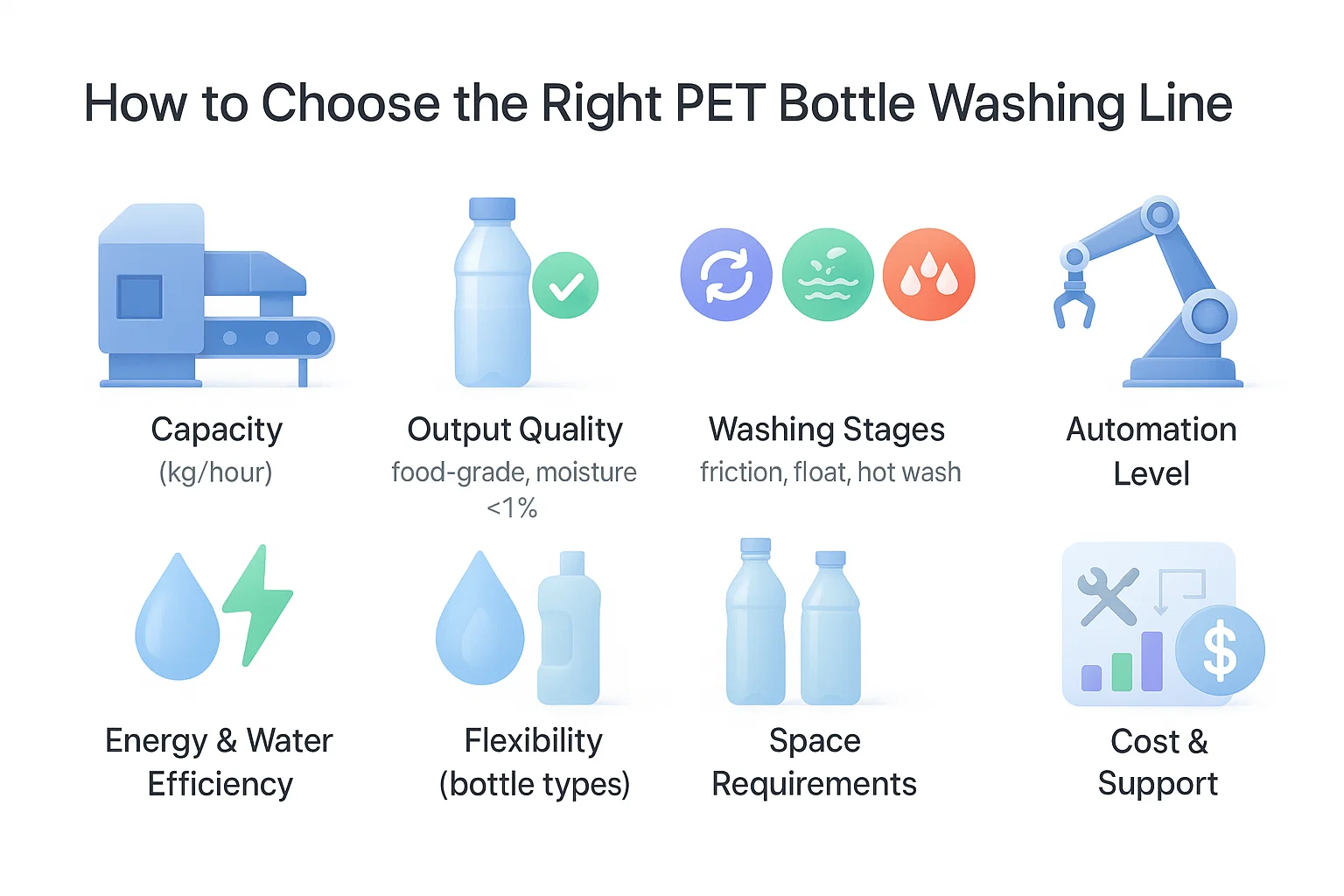

Selecting the right PET bottle washing line is crucial for ensuring efficient production, consistent output quality, and long-term operational success. Whether you're entering the recycling business or scaling up your current operations, it's essential to consider several key factors to make an informed decision.

1. Assess Your Processing Capacity

Begin by determining how much PET material—bottles or flakes—you plan to process per hour or per day. Washing lines typically range from 500 kg/h to over 5000 kg/h, with customized solutions reaching 6000 kg/h or more.

Choosing a system that aligns with your actual production needs will help avoid the pitfalls of underutilization or overinvestment.

2. Define the Required Output Quality

Consider whether your end product must meet food-grade standards, which require high purity and additional processing steps such as hot washing and advanced sorting.

Ensure the system consistently delivers flakes with low moisture content (below 1%) and minimal contamination, especially PVC, labels, or metals.

3. Examine Washing Efficiency and Technology

Efficient washing lines use a multi-stage process to maximize cleanliness and quality. Look for systems that include:

- Friction washing

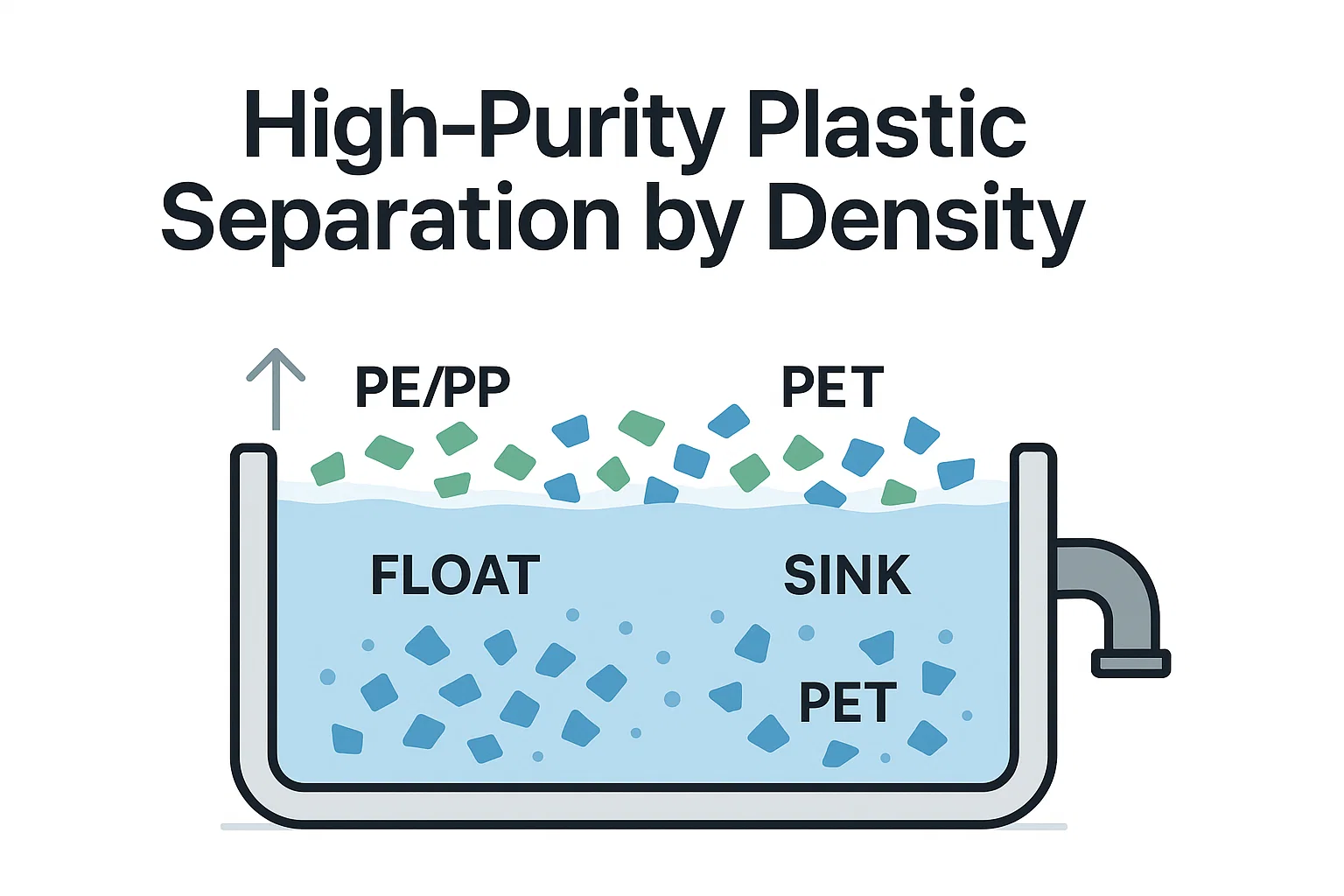

- Float-sink separation

- Hot washing

- Density separation

These technologies reduce the need for reprocessing and help maintain high-quality output.

4. Consider Automation and User-Friendliness

Automation can significantly improve operational consistency and reduce labor costs. However, higher automation levels may come with increased initial investment.

Select a system that balances automation with your team’s technical skills and maintenance capabilities.

5. Evaluate Energy and Water Efficiency

Choose equipment designed to minimize energy and water usage, which directly impacts your long-term operating costs.

Modern washing lines often include closed-loop water systems and energy-efficient motors to enhance sustainability and reduce waste.

6. Ensure Flexibility and Adaptability

If your input materials vary—different bottle sizes, colors, or contamination levels—opt for a system that can adapt to diverse feedstock.

Versatile lines improve ROI and help you remain responsive to evolving market demands.

7. Account for Space and Installation Requirements

Carefully assess your facility’s layout and select equipment that fits your available space. Many manufacturers offer customized layouts to optimize floor space and workflow without compromising performance.

8. Compare Costs and After-Sales Support

While upfront equipment cost is important, also consider:

- Performance metrics

- Warranty terms

- Maintenance and parts availability

- Quality of after-sales service

Choosing a reliable supplier ensures long-term operational continuity and reduces downtime.

✔ Summary Checklist: Choosing the Right PET Bottle Washing Line

- Capacity: Align with your expected processing volume (e.g., 500–5000+ kg/h).

- Output Quality: Ensure compliance with purity standards (food-grade if necessary).

- Washing Efficiency: Look for comprehensive, multi-stage cleaning systems.

- Automation: Choose automation based on budget and workforce capabilities.

- Resource Consumption: Opt for systems with low energy and water usage, preferably with recycling features.

- Flexibility: Ensure the line can handle varying input materials.

- Space Requirements: Confirm the system fits within your facility without disruption.

- Total Cost of Ownership: Balance purchase cost, efficiency, maintenance, and service.

By thoroughly evaluating these aspects in light of your business objectives, you can invest in a PET bottle washing line that enhances production efficiency, product quality, and cost-effectiveness, ensuring both immediate and long-term success.

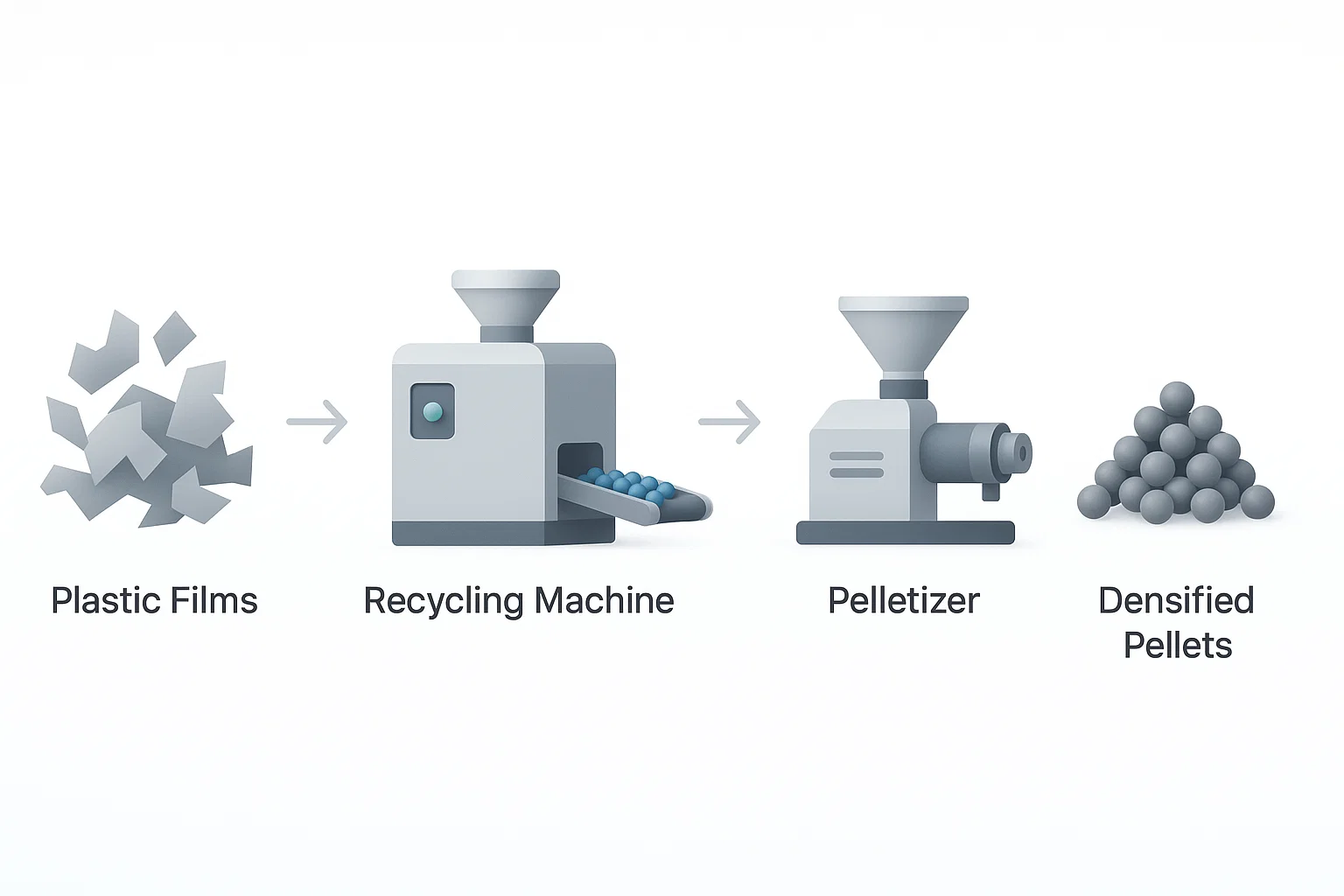

The PP/PE Film Shredding and Densifying Line enhances plastic recycling efficiency through several key functionalities:

- Moisture Reduction:

The line incorporates a screw press squeezer that effectively reduces moisture content in washed plastic films—from approximately 30–40% down to 2–5%. This substantial reduction in moisture significantly lowers the energy demands of subsequent drying stages, which are typically energy-intensive, thereby decreasing operational costs and improving overall process efficiency. - Increased Volume Efficiency and Bulk Density:

By compacting shredded and washed plastic flakes into dense pellets (with a bulk density of approximately 350–410 kg/m³), the system reduces the material’s volume by up to 90%. This densification improves the efficiency of storage, handling, and transportation, resulting in lower logistics costs and smoother downstream processing. - Uniform and Consistent Feedstock:

The densified pellets—typically around 50 mm in length—exhibit uniformity in size and density, which ensures more consistent feeding into extruders and pelletizing systems. This consistency minimizes the risks of bridging and feed interruptions, reduces equipment wear, and ultimately leads to increased throughput and improved quality of recycled outputs. - Enhanced Purity through Contaminant Removal:

Before densification, the system utilizes sink-float separation to remove heavy contaminants, including stones and dirt. In certain configurations, the screw squeezer also removes residual fine particles. These features collectively enhance feedstock purity and contribute to the production of higher-quality recycled pellets. - Improved Downstream Processing:

The resulting semi-dry, densified pellets are ideally suited for both mechanical pelletizing and chemical recycling. Their optimized properties enable faster and more energy-efficient extrusion and molding processes in subsequent recycling phases - Operational Efficiency and Flexibility:

Engineered for ease of operation and maintenance, the line minimizes downtime and enhances productivity. Modular and customizable configurations allow adaptation to specific processing capacities and material requirements, offering added flexibility and scalability to recycling operations.

Conclusion:

The PP/PE Film Shredding and Densifying Line significantly improves the recyclability of plastic films by converting bulky, wet, and contaminated waste into dense, dry, and uniform material. This transformation streamlines feeding into recycling equipment, reduces energy and transportation costs, and enhances the consistency and quality of recycled plastics. As a result, the line supports more sustainable, cost-effective, and high-throughput plastic film recycling operations.

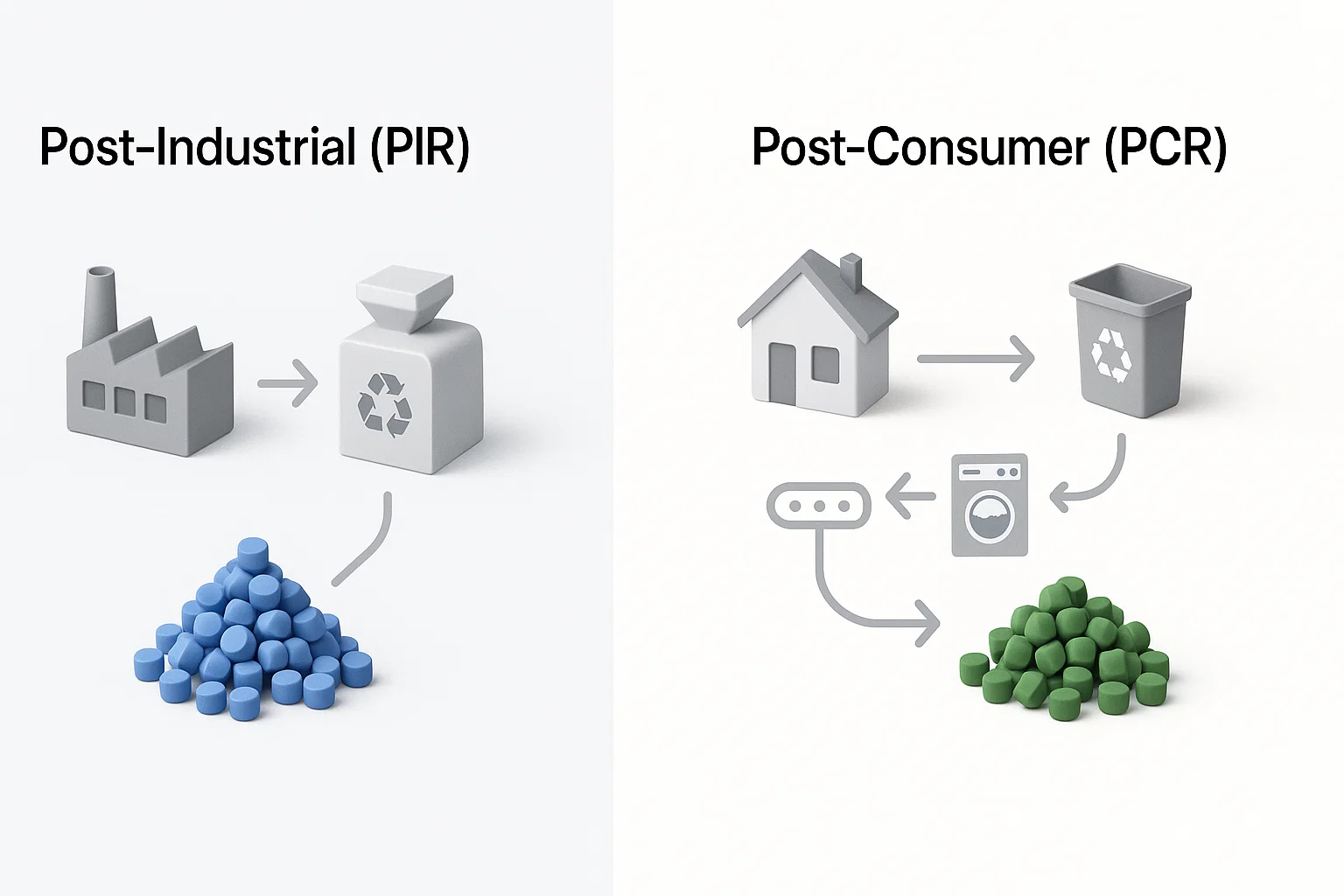

In today’s manufacturing landscape, the drive for sustainability and efficiency has never been more critical. Recycled plastic pellets are at the forefront of this movement, offering a powerful alternative to virgin raw materials. But not all recycled pellets are created equal. The source of the plastic waste—whether it's from a factory floor or a household recycling bin—makes a significant difference.

This guide will explore the key benefits and limitations of using recycled plastic pellets, focusing on the two primary sources:

- Post-Industrial Resin (PIR): Also known as pre-consumer waste, this is clean scrap material recovered from internal manufacturing processes.

- Post-Consumer Resin (PCR): This is plastic reclaimed from household or commercial waste streams after it has been used by the consumer.

Understanding the distinction is key to making the right choice for your production line.

The Compelling Benefits of Using Recycled Pellets

Opting for recycled pellets can unlock significant advantages for manufacturers, impacting everything from the budget to your brand's environmental credentials.

1. Significant Cost Reduction

This is often the most immediate and tangible benefit. Procuring virgin raw materials is a major operational expense. By recycling in-house waste, you can capture and reuse material that would otherwise be lost. Post-industrial waste can account for 5% or more of a production line's output. Turning this scrap into high-quality pellets through an in-house recycling system is a financially astute decision that directly cuts down on raw material costs.

2. Consistent, High-Quality Material (Especially from PIR)

Pellets generated from post-industrial sources are often described as being "almost like new." Because the material has never been used by a consumer, it is free from contamination and its properties are known and consistent. The uniform size and purity of these PIR pellets make them ideal for direct reintegration into demanding processes like extrusion, ensuring the final product meets high-quality standards.

3. A Greener Footprint

Using recycled plastic pellets significantly reduces your environmental impact. Every tonne of recycled plastic used is a tonne of virgin plastic that doesn't need to be manufactured. This conserves fossil fuels, reduces energy consumption, and lowers greenhouse gas emissions associated with plastic production. It's a clear and marketable step towards becoming a more sustainable business.

4. Seamless Integration and Versatility

One of the primary advantages is the ease with which recycled pellets can be reintroduced into your production line. They are a versatile raw material suitable for a wide range of applications, including:

- Blown film extrusion (e.g., for industrial packaging)

- Pipe extrusion (e.g., for drainage or conduits)

- Manufacturing products like refuse sacks and LDPE pipes

In some cases, especially when using high-quality PIR, the process is as simple as feeding the recycled pellets back into the extruder.

Navigating the Challenges: Limitations to Consider

While the benefits are clear, it's important to be aware of the potential limitations, particularly when working with post-consumer materials.

1. Variability in Post-Consumer (PCR) Quality

Unlike the clean and uniform nature of PIR, post-consumer waste presents more challenges. Pellets derived from PCR sources can exhibit greater variability in quality. This is due to several factors:

- Contamination: Residue from food, drink, paper labels, and adhesives.

- Mixed Materials: A single bale of waste may contain multiple types of plastic that need careful sorting.

- Degradation: The plastic may have been exposed to sunlight (UV degradation) or other elements that weaken its structure.

Thorough washing, sorting, and processing are essential to creating usable PCR pellets, which adds complexity to the recycling process.

2. Potential for Reduced Mechanical Properties

The process of being melted and re-formed can sometimes shorten the polymer chains in plastic, which may lead to slightly reduced mechanical properties (such as tensile strength or impact resistance) compared to its virgin equivalent. This is a more significant consideration for PCR materials which may have already undergone multiple stresses.

However, this can often be mitigated. The quality of PCR pellets can be significantly enhanced by incorporating masterbatches and performance-enhancing additives directly during the recycling and pelletising process. Furthermore, for many applications, a slight reduction in mechanical properties is perfectly acceptable. In certain products, like refuse sacks, it's even feasible to use 100% recycled content from post-consumer sources.

PIR vs. PCR: A Quick Comparison

| Feature | Post-Industrial Resin (PIR) | Post-Consumer Resin (PCR) |

| Source | In-house manufacturing scrap | Household & commercial waste |

| Quality | High, consistent, "like new" | Variable, depends on sorting |

| Contamination | Very low to none | High potential for contamination |

| Cost to Process | Lower | Higher (due to cleaning/sorting) |

| Best For | High-quality products, direct reintegration | Products where 100% recycled content is a goal & slight variability is acceptable |

Conclusion: A Smart, Sustainable Choice

Recycled plastic pellets offer a powerful pathway to more cost-effective and environmentally responsible manufacturing. While pellets from post-industrial sources provide a straightforward route to high-quality, low-cost material, the challenges of post-consumer recycling are being overcome with advanced sorting and processing technologies.

By understanding the distinct characteristics of PIR and PCR, manufacturers can make strategic decisions, selecting the right material for the right application. The result is a streamlined production cycle, a healthier budget, and a tangible contribution to the circular economy.