Recycling News

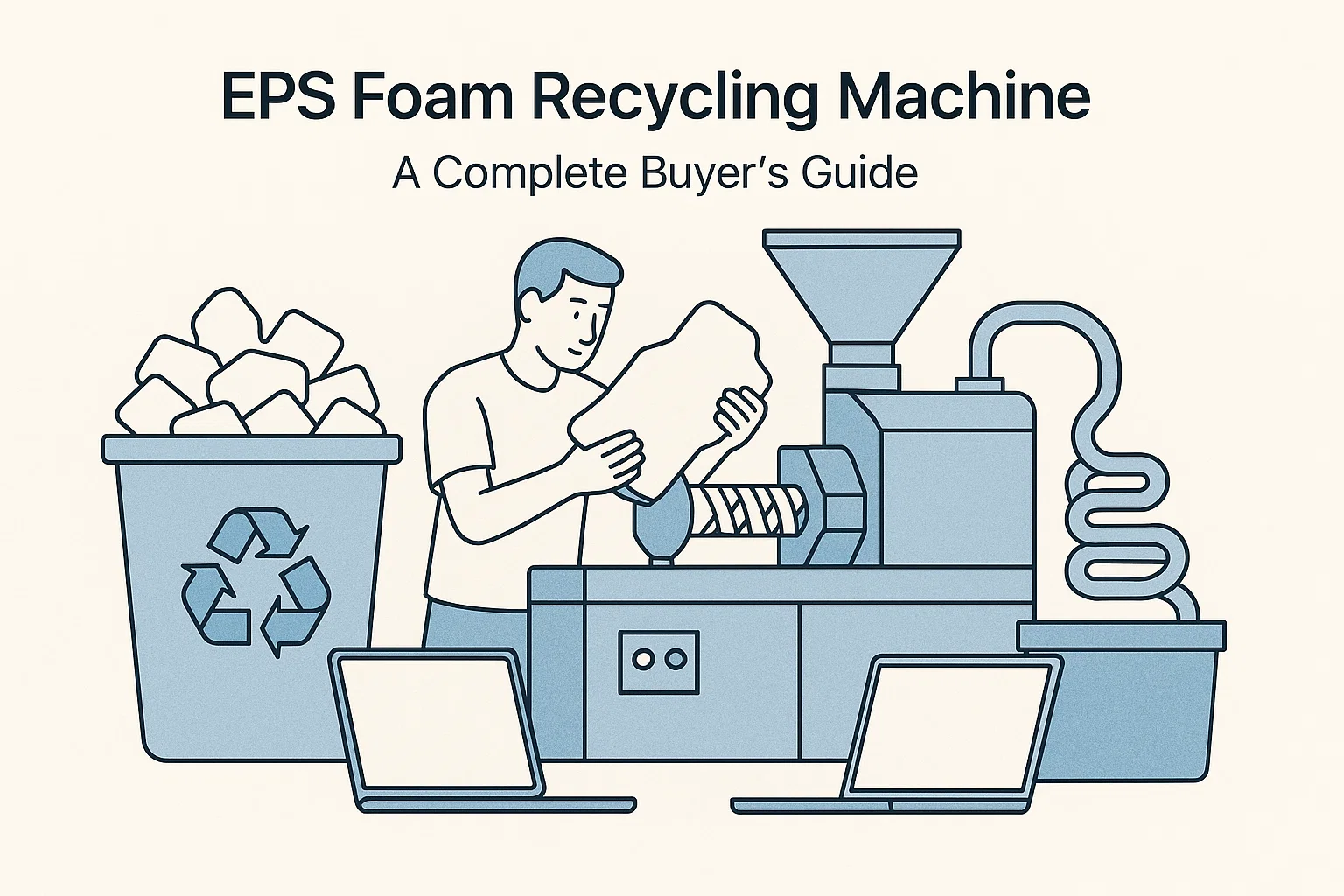

Foam waste presents a significant environmental challenge due to its bulky nature and slow degradation. Fortunately, foam recycling machines offer an innovative solution by converting this problematic waste into valuable, reusable materials. This comprehensive guide explores how these machines work and why they're essential for sustainable waste management.

Understanding the Foam Recycling Process

The transformation of foam waste into reusable materials involves a carefully orchestrated series of steps, each playing a crucial role in the overall recycling process.

Collection and Sorting: The Foundation of Effective Recycling

The journey begins with gathering foam materials from businesses, recycling centers, and collection points. This includes expanded polystyrene (EPS)—commonly known as Styrofoam—as well as other foam varieties used in packaging, insulation, and consumer products.

Proper sorting is absolutely essential at this stage. Different foam types require different processing methods, and contaminants like tape, labels, or mixed materials can significantly reduce recycling efficiency. Taking time to separate materials properly ensures smoother processing and higher-quality output.

Size Reduction: Making Bulk Manageable

Once sorted, the foam enters shredders or grinders that break it down into smaller pieces. This step addresses one of foam's biggest challenges: its extremely low density and bulky nature.

By reducing particle size, these machines create a more uniform material that's easier to handle in subsequent processing stages. Smaller particles also allow for better compression ratios during densification, ultimately improving the efficiency of the entire recycling operation.

Densification: The Critical Transformation

Densification represents the heart of foam recycling. Foam recycling machines use specialized compactors or densifiers that apply heat and pressure to dramatically reduce foam volume—often by 90% or more.

Some machines use thermal methods, applying controlled heat to soften and compress the foam. Others rely on mechanical compression, using powerful hydraulic systems to squeeze the material into dense blocks. This transformation is what makes foam recycling economically viable, as it reduces storage space requirements and transportation costs by up to 50 times.

Extrusion: Creating Raw Materials for Manufacturing

For polystyrene foam and certain other types, extrusion takes recycling a step further. These advanced machines melt the compacted foam and force it through specialized dies, creating uniform plastic pellets or custom profiles.

The resulting pellets match specifications for manufacturing applications, allowing them to be used as feedstock for new products. This process essentially returns the foam to its original raw material form, ready to begin its lifecycle again.

Output and Reuse: Closing the Loop

The final output from foam recycling takes several forms, each with specific applications:

Densified blocks or ingots serve as lightweight filler material in construction projects, soundproofing applications, and as spacers in shipping containers. Their uniform density and shape make them easy to work with and transport.

Plastic pellets become the foundation for new products, including picture frames, crown molding, office supplies, and even new foam products. Many manufacturers actively seek recycled foam pellets as a sustainable alternative to virgin materials.

Custom extruded profiles can be created directly for specific applications, eliminating the need for additional manufacturing steps and reducing overall production costs.

Types of Foam Recycling Equipment

Understanding the different machine types helps businesses select the right equipment for their needs.

Shredders and Grinders

These machines focus exclusively on size reduction and typically serve as the first step in larger recycling operations. They're ideal for facilities processing large volumes of mixed foam waste.

Compactors

Compactors use mechanical pressure to reduce foam volume without melting. They're perfect for businesses that generate foam waste regularly but may not have the space for full recycling lines. The compacted material can then be transported to facilities with more advanced processing equipment.

Densifiers

Densifiers combine heat and mechanical pressure to create extremely dense blocks or ingots. These machines offer higher compression ratios than cold compactors and produce output that's easier to store and transport over long distances.

Extruders

Extruders represent the most advanced foam recycling technology, melting and reshaping material into pellets or profiles ready for manufacturing. While they require higher upfront investment, they produce the highest-value output and are essential for businesses aiming to create closed-loop recycling systems.

Why Foam Recycling Matters

Environmental Protection

Foam waste occupies enormous space in landfills and can persist for hundreds of years without degrading. By recycling foam, we dramatically reduce the volume of waste requiring disposal and prevent harmful materials from accumulating in our environment.

Resource Conservation

Every ton of recycled foam reduces demand for virgin petroleum-based polymers. This conserves finite natural resources and reduces the environmental impact associated with extracting and processing raw materials.

Economic Opportunities

Recycling creates tangible economic value. Businesses can generate revenue from materials they previously paid to dispose of. The recycled foam market continues to grow, with increasing demand from manufacturers seeking sustainable materials.

Supporting Circular Economy Goals

Foam recycling machines help companies transition from linear "take-make-dispose" models to circular systems where materials continuously cycle through use, recovery, and remanufacturing. This approach aligns with global sustainability initiatives and increasingly stringent environmental regulations.

Key Considerations for Implementation

Equipment Selection

Choose equipment based on your specific foam types, processing volume, and space constraints. Consider whether you need a single machine or an integrated recycling line, and evaluate both capital costs and long-term operational efficiency.

Staff Training

Proper training ensures safe, efficient operation and maximizes equipment lifespan. Operators should understand sorting requirements, safety protocols, and basic troubleshooting procedures.

Regular Maintenance

Implement a preventive maintenance schedule to keep machines running smoothly. Regular cleaning, lubrication, and inspection prevent costly breakdowns and ensure consistent output quality.

Quality Control

Establish procedures for monitoring output quality. Consistent density, minimal contamination, and proper sizing ensure your recycled materials meet market specifications and command premium prices.

Frequently Asked Questions

What types of foam can be recycled in these machines?

Most foam recycling machines handle expanded polystyrene (EPS), extruded polystyrene (XPS), and polyethylene foam. Each machine type has specific capabilities, so it's important to match equipment to your foam types. Some advanced systems can process multiple foam varieties, while others specialize in specific materials for optimal efficiency.

How much space reduction can foam recycling machines achieve?

Modern foam recycling equipment typically reduces foam volume by 90-98%, depending on the machine type and processing method. Cold compactors generally achieve 40:1 to 50:1 compression ratios, while hot-melt densifiers and extruders can reach 90:1 ratios or higher. This dramatic reduction makes storage and transportation economically viable.

What is the ROI timeline for investing in foam recycling equipment?

Return on investment varies based on your foam waste volume, equipment costs, and local market conditions for recycled materials. Businesses processing significant foam volumes often see payback periods of 1-3 years through combined savings on disposal costs and revenue from selling recycled materials. Smaller operations may take longer but still achieve positive returns.

Can recycled foam match virgin material quality?

Yes, properly processed recycled foam can meet quality standards comparable to virgin materials for many applications. The key lies in proper sorting, contamination control, and processing parameters. While some high-specification applications still require virgin materials, recycled foam serves excellently in construction materials, new packaging, consumer products, and many manufacturing applications.

What are the main operating costs for foam recycling machines?

Operating costs include electricity (the largest variable cost), maintenance parts, labor, and occasional repairs. Energy-efficient models can process foam for just a few cents per pound. Regular preventive maintenance minimizes unexpected repair costs. Most businesses find that operational costs are more than offset by disposal savings and material sales revenue, making foam recycling highly cost-effective over time.