Plastic Recycling Machines & Turnkey Lines

Turn PET, HDPE, PP and PE film into high‑quality, market‑ready pellets with synchronized washing, drying, filtration and pelletizing — engineered for stable throughput and consistent quality.

Get a Custom QuoteAbout Energycle & Editorial Review

What We Do

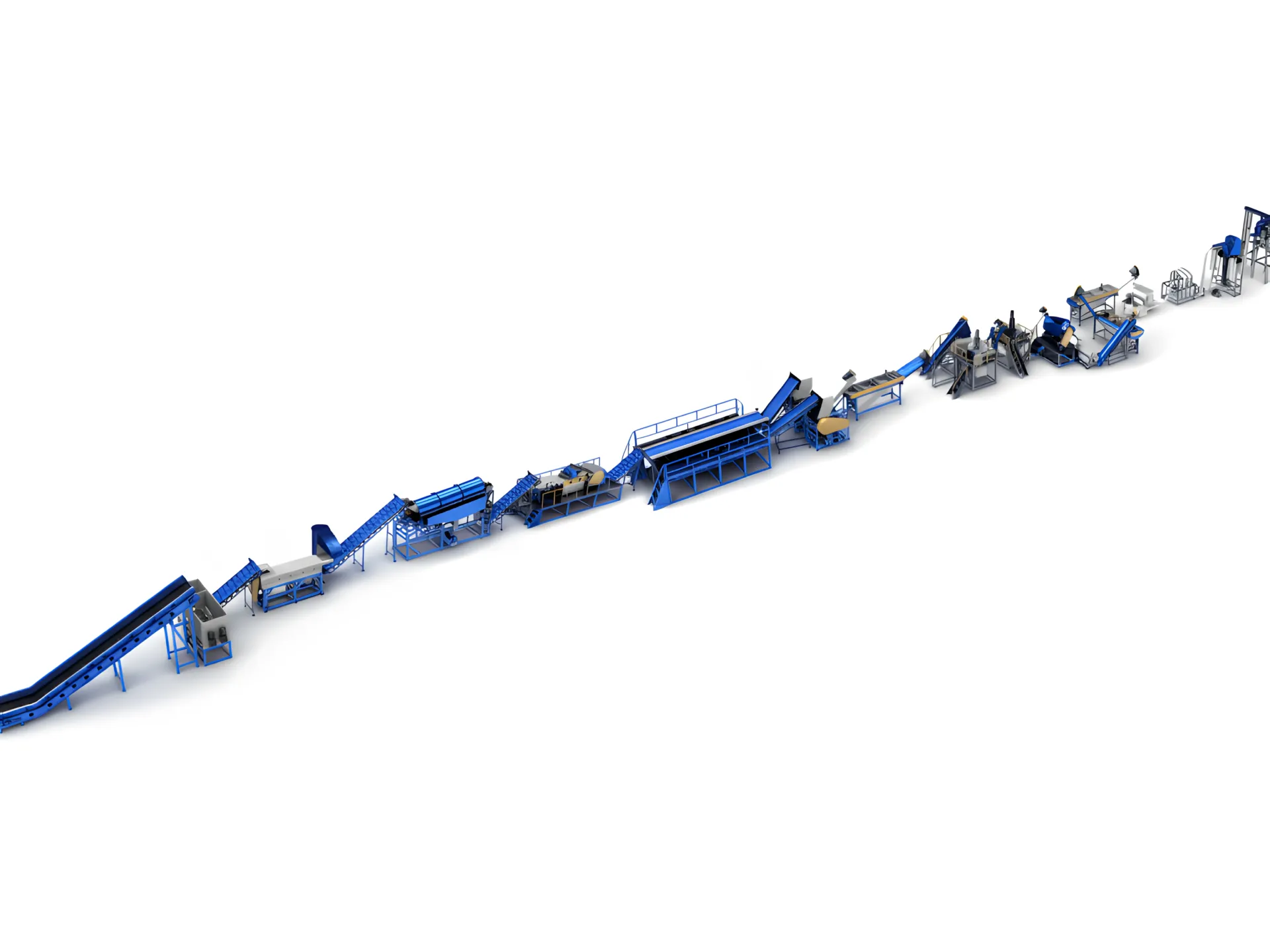

Energycle designs and manufactures plastic recycling equipment and turnkey lines spanning sorting, size reduction, washing, drying and pelletizing. Every configuration is tailored to your materials, cleanliness and capacity targets.

Quality & Compliance

Built under an ISO 9001 quality system with CE‑compliant machines. Safety, energy efficiency and maintainability are designed into each module.

How to Engage

Share your feedstock and goals and our engineers will recommend a matched lineup and line layout. For site visits or references, contact us: Contact Sales.

What Is a Plastic Recycling Machine?

An integrated, modular system that converts sorted plastic waste into clean flakes or pellets through staged size‑reduction, washing, drying and pelletizing.

A plastic recycling machine (often configured as a full line) combines multiple modules to process post‑consumer or post‑industrial plastics. Typical lines include automated conveying, shredding or granulation, intensive washing with separation, dewatering and thermal drying, and finally extrusion with filtration, degassing and pellet cutting. The result is high‑purity flakes or uniform pellets that are ready for reuse in manufacturing.

Our systems are designed to be modular and scalable, so you can start with essentials and expand capacity or capability (e.g., adding color sorting) as your business grows.

500-3000 kg/h

< 1%

98%+

24/7

Why Invest in Professional Recycling Lines?

High ROI & Efficiency

Optimized for low energy consumption per ton and high throughput, maximizing your resale value.

Closed-Loop Quality

Produce pellets suitable for high-end applications like bottle-to-bottle or film-to-film.

Intelligent Automation

PLC Integrated control ensures consistent operation and reduces labor dependency.

Sustainable Compliance

Zero-discharge water treatment options available to meet strict environmental regulations.

From Pain Points to Results

Contaminated & Mixed Feed

Labels, sand, organics and density mix hurt purity and damage equipment.

Intensive Washing + Separation

Friction wash, float‑sink and optional hot wash raise purity and protect downstream equipment.

High Moisture After Wash

Wet flakes cause voids and gels during extrusion and degrade pellet quality.

Dewatering & Thermal Drying

Centrifuge plus controlled drying helps achieve target moisture for void‑free pellets.

Unstable Output Specs

Impurities and volatiles lead to odor, color shift and MFI drift.

Filtration + Degassing Control

Fine filtration and dual‑stage degassing stabilize MFI and color for market‑ready pellets.

How It Works

End‑to‑end process engineered to deliver clean, dry flakes and uniform pellets.

1. Sorting & Separation

Remove metals, glass, paper and separate by polymer/color for higher purity. View equipment →

2. Size Reduction

Shredders and granulators create uniform flakes, improving downstream cleaning efficiency. View machines →

3. Washing & Cleaning

Friction washers, float‑sink and hot wash remove labels, glue and residues. View systems →

4. Dewatering & Drying

Centrifugal dewatering and thermal drying reach moisture targets for extrusion. View dryers →

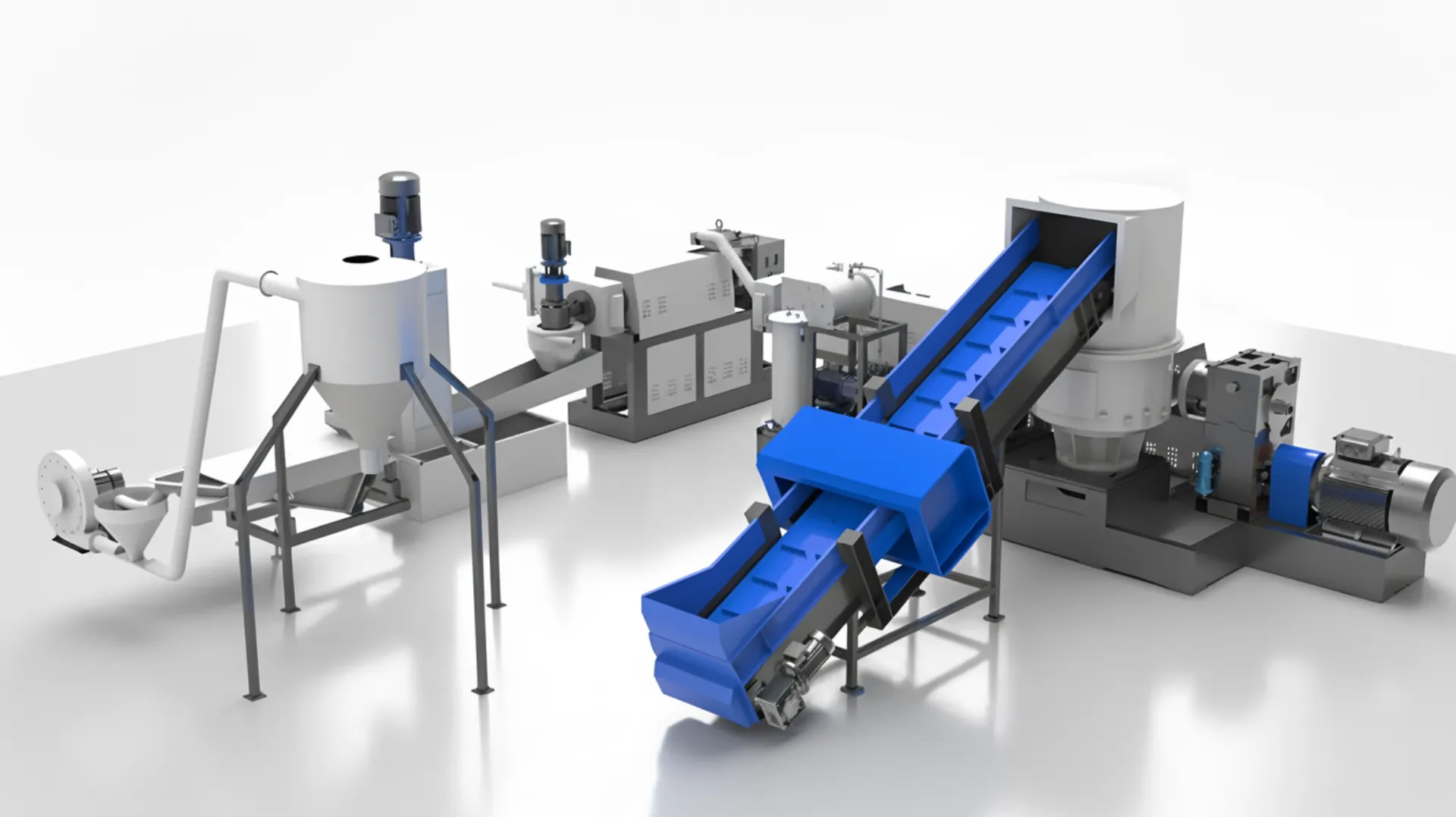

5. Melting & Pelletizing

Extrusion with filtration, degassing and strand cutting for uniform, market‑ready pellets. See pelletizers →

Explore Our Product Lines

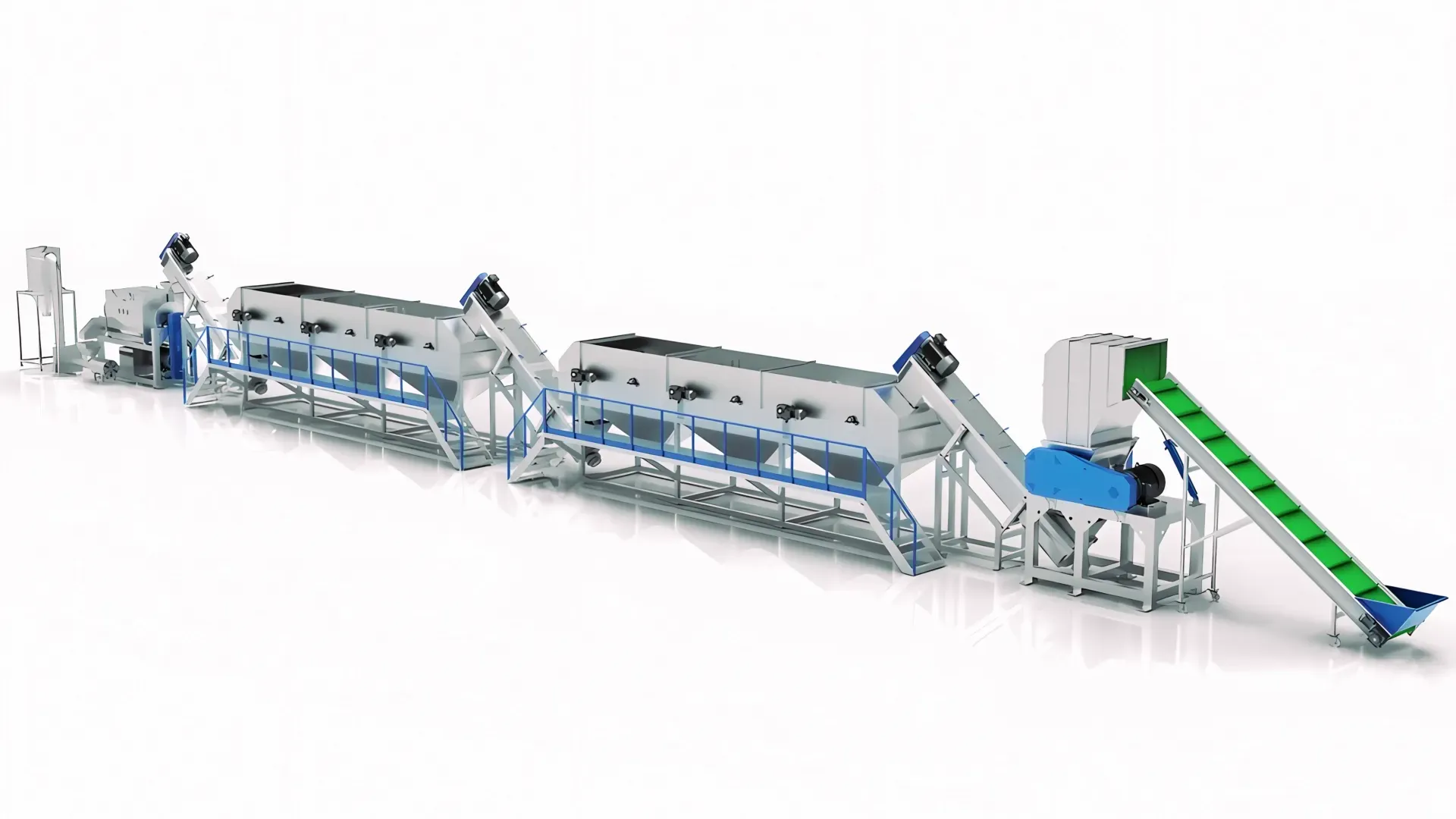

Plastic Washing Lines

Turnkey lines for crushing, washing and drying contaminated plastics. From agro film to rigid bottles.

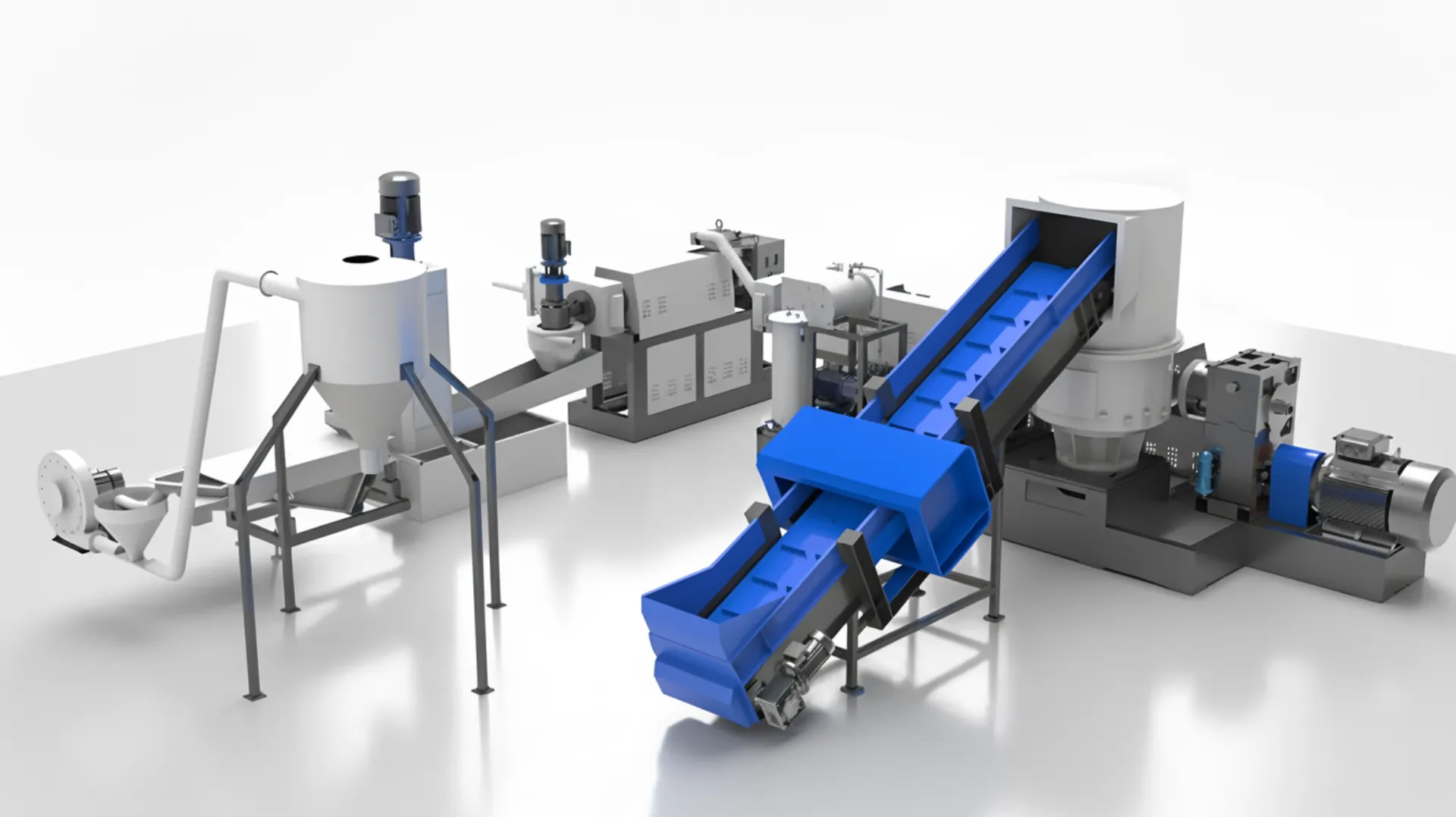

Pelletizing Extruders

High-performance extrusion with filtration and degassing for market-ready uniform pellets.

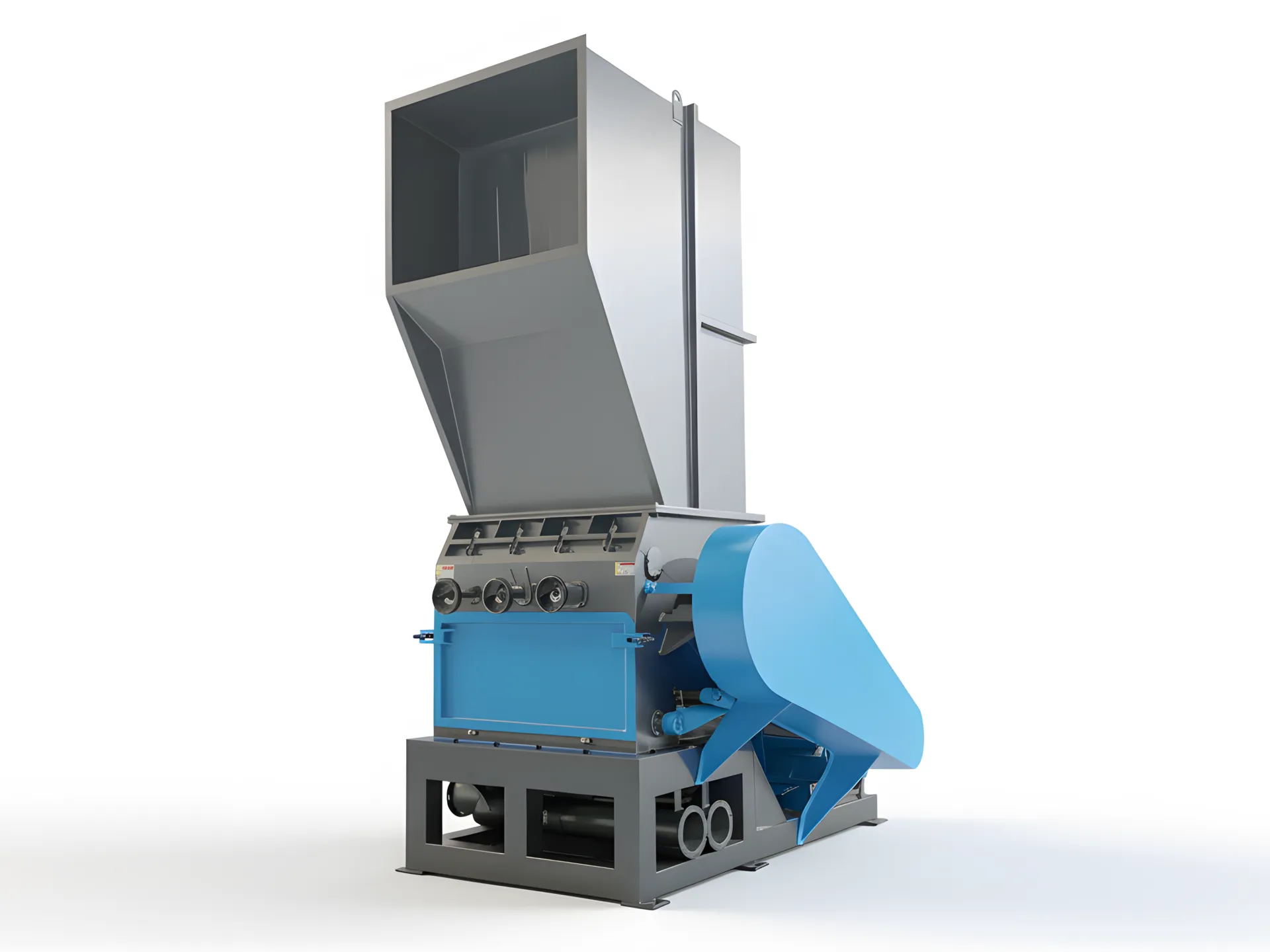

Plastic Shredders

Low-speed, high-torque single and double shaft shredders for tough heavy-duty materials.

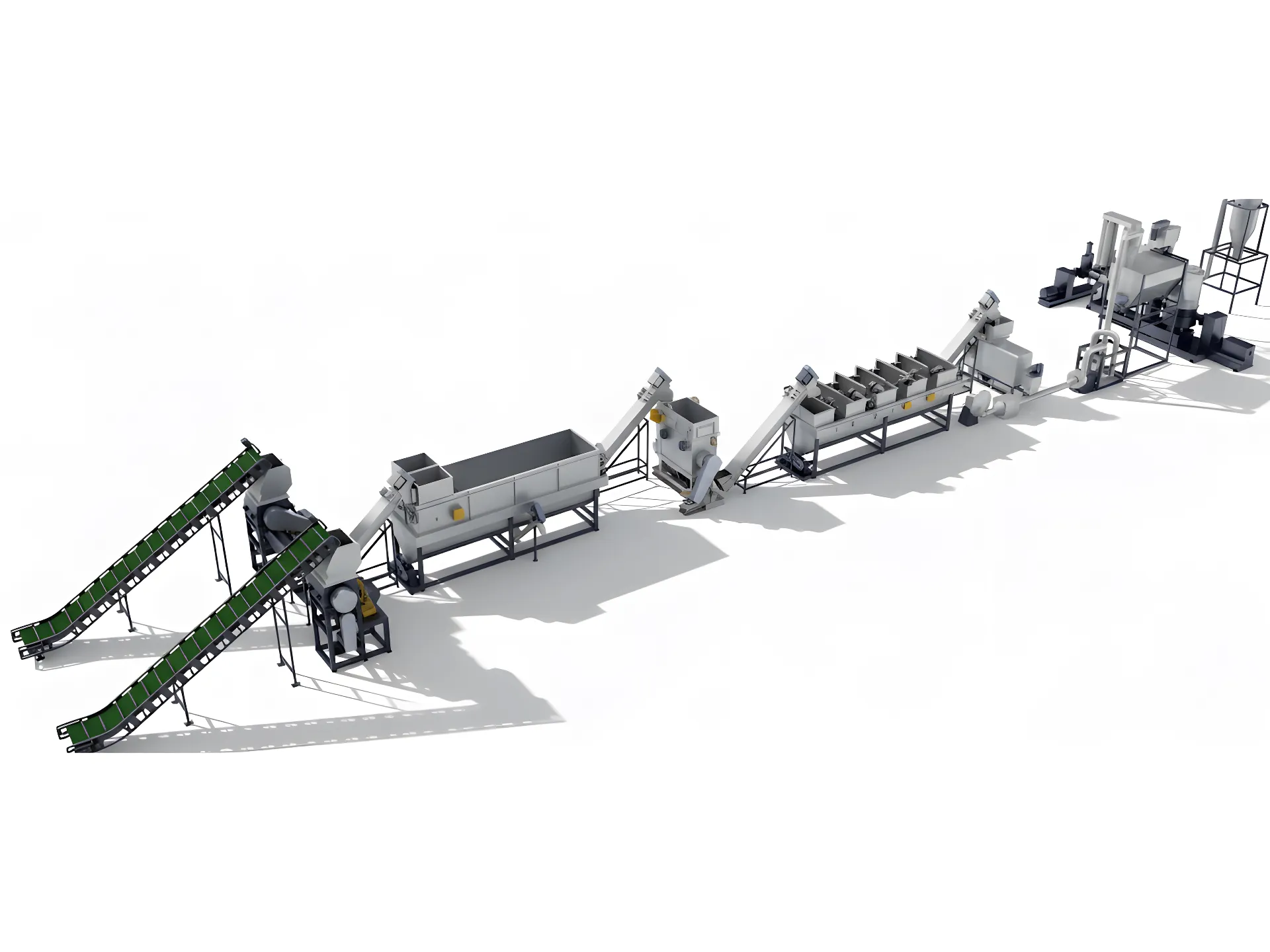

Plastic Granulators

High-speed crushers and grinders to process rigid plastics into uniform, small flakes.

Drying Systems

Mechanical and thermal drying solutions to achieve <1% moisture content for high-quality reuse.

Densification Systems

Highly efficient mechanical dewatering and compacting for washed plastic films and woven bags.

Materials We Process & Typical Capacities

Compatible Plastics

- PET bottles and flakes (food/non‑food grade)

- HDPE/PP rigid containers, caps and crates

- PE film, agricultural film, raffia & woven bags

- Mixed post‑consumer and post‑industrial streams

300-500 kg/h

Compact line offering.

800-1200 kg/h

Balanced throughput.

1500-2000 kg/h

High‑throughput scale.

≤1-2% Moisture

High drying efficiency.

See It In Action

Our Recycling Plants in Action

Customer Success Stories

PE Film → Recycled Pellets, Europe

Compact 800 kg/h line with hot washing and cutter‑compactor pelletizing.

PET Bottles → RPET Flakes, Asia

1200 kg/h with label remover, friction wash, dewatering and crystallization.

Frequently Asked Questions

Can the line be customized for my specific type of plastic waste?

What is involved in a "turnkey" project?

What is typical ROI?

What Our Customers Say

"Throughput hit target within the first week. The washing upgrade lifted purity and reduced filter changes dramatically."

"Moisture control plus dual‑degassing stabilized our MFI. We now sell into higher‑value applications."

"Installation was smooth and training was practical. The team helped tune recipes for our mixed feedstock."

Get a Custom Quote

Tell us about your materials, capacity targets, and site conditions. Our engineering team will propose a tailored plastic recycling line.

Contact Sales