A Comprehensive Guide to Foam Recycling Machines: Types, Benefits, and Applications

The Challenge: Foam waste, particularly expanded polystyrene (EPS) and polyurethane (PU) foam, represents a significant environmental challenge in today’s industrial landscape. Used extensively in packaging, insulation, and manufacturing applications, foam materials are non-biodegradable and consume substantial landfill space when improperly managed.

The Solution: Foam recycling machines provide an innovative, cost-effective approach to managing foam waste by enabling businesses to process, compress, and repurpose these materials into valuable resources while significantly reducing their environmental footprint.

Understanding Foam Recycling Machines

A foam recycling machine is specialized equipment engineered to process and recycle various types of foam waste efficiently. These machines employ different technologies—including mechanical compression, thermal melting, and shredding—to transform bulky foam waste into dense, manageable materials suitable for repurposing.

By implementing EPS recycling solutions, businesses can dramatically reduce their environmental impact, minimize landfill dependency, and significantly lower waste management expenses while contributing to a circular economy.

Types of Foam Recycling Machines: Selecting the Right Technology

1. Cold Compactors

Cold compactors represent an energy-efficient solution for businesses managing large volumes of expanded polystyrene (EPS) foam. These machines utilize mechanical pressure without heat application to compress foam waste into compact blocks, achieving volume reduction rates of 50-90%.

2. Hot Melting Machines

Hot melting machines employ thermal technology to melt and densify foam waste efficiently. Foam material is fed into a heated chamber where it melts and is subsequently extruded as dense blocks or ingots, achieving impressive densification ratios up to 90:1.

3. Thermal Densifiers

Thermal densifiers apply controlled heat to soften and compress foam waste without complete melting. This technology offers efficient densification while maintaining material integrity, making transportation and recycling processes more economical.

4. Shredders and Granulators

Shredders and granulators mechanically break down foam materials into small pieces or granules that can be directly reused in manufacturing processes or further processed. These machines excel at handling polyurethane (PU) foam commonly found in furniture and bedding applications.

Key Benefits of Investing in Foam Recycling Machines

Substantial Cost Reduction

Foam’s lightweight yet voluminous nature results in significant transportation and landfill disposal fees. Recycling machines reduce foam volume by up to 90%, dramatically cutting waste management expenses. Businesses typically achieve ROI within 18-36 months through disposal cost savings alone.

Environmental Impact Mitigation

Foam materials can persist in landfills for hundreds of years without decomposing. By recycling foam waste, companies actively participate in circular economy initiatives, reducing greenhouse gas emissions associated with foam production and landfill management while conserving natural resources.

Revenue Generation Opportunities

Recycled foam blocks, ingots, and granules possess commercial value in secondary markets. Manufacturers actively purchase recycled foam materials for use in construction, packaging, and manufacturing applications, creating an additional revenue stream that offsets equipment investment costs.

Enhanced Corporate Sustainability Profile

Modern consumers and B2B clients increasingly prioritize partnerships with environmentally responsible companies. Implementing foam recycling demonstrates tangible commitment to sustainability, strengthening brand reputation, meeting ESG (Environmental, Social, and Governance) criteria, and potentially opening new market opportunities.

Industry Applications: Where Foam Recycling Delivers Maximum Value

Packaging Industry

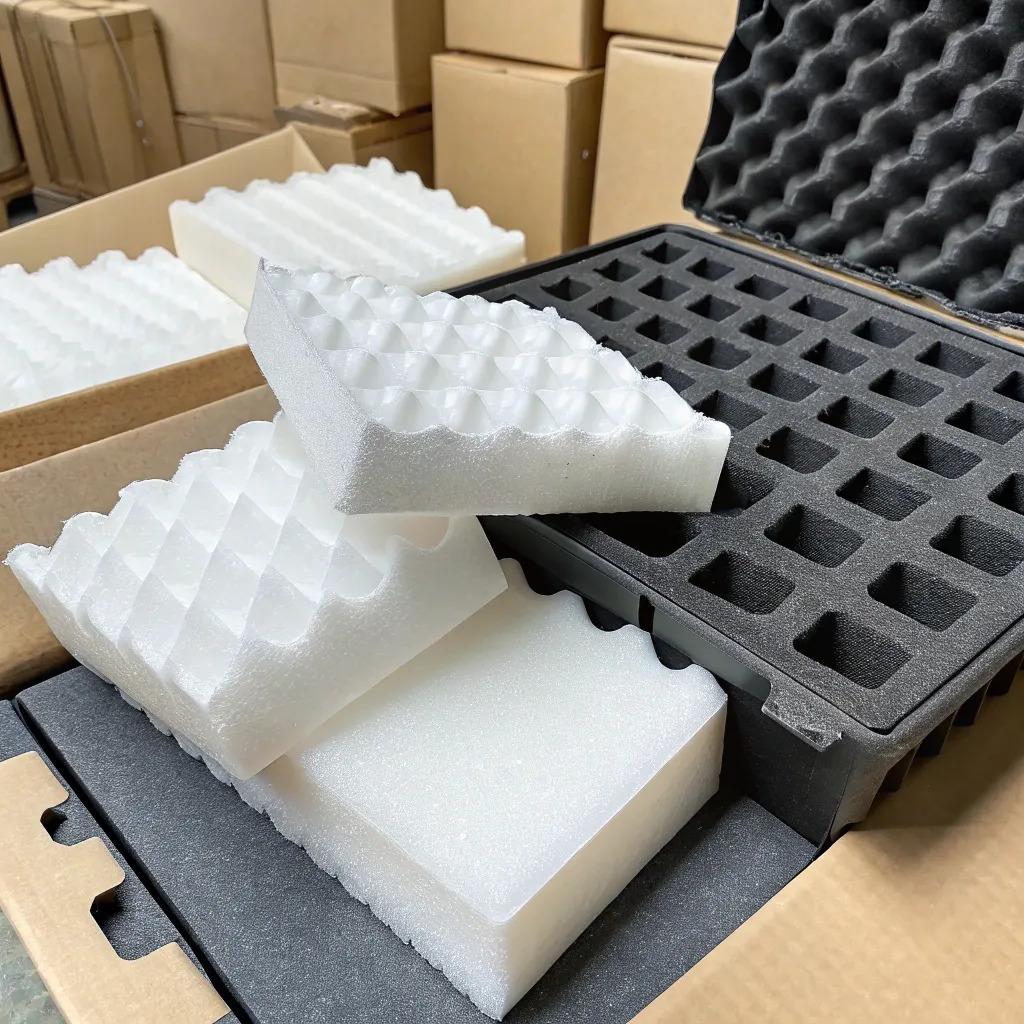

Packaging operations generate substantial EPS foam waste from protective materials. Recycling machines transform this waste into compact blocks, reducing storage requirements and disposal costs while supporting sustainable packaging initiatives and meeting corporate sustainability goals.

Furniture Manufacturing

Polyurethane foam constitutes a major component in furniture cushioning. Manufacturers utilizing shredders and granulators can recycle production scrap and end-of-life products, creating closed-loop manufacturing systems that reduce raw material costs and environmental impact.

Construction and Insulation

Construction projects frequently utilize EPS and XPS foam for insulation and structural applications. Hot melting machines and densifiers enable contractors to recycle leftover materials and demolition waste, reducing project costs and meeting green building certification requirements.

Electronics and Appliance Manufacturing

Electronics manufacturers use foam extensively for protective packaging during product shipment. On-site foam recycling capabilities reduce waste management complexity, lower disposal costs, and demonstrate compliance with extended producer responsibility regulations.

Selecting the Optimal Foam Recycling Machine: Decision Framework

Choosing the appropriate foam recycling equipment requires careful evaluation of multiple operational and financial factors:

- Foam Type Identification: Different machines excel with specific foam types. EPS and XPS foam work best with cold compactors, hot melters, and densifiers, while PU foam requires shredding or granulation equipment. Accurately identify your waste stream composition before equipment selection.

- Processing Volume Assessment: Match machine capacity to your waste generation rate. Small operations may succeed with cold compactors, while high-volume facilities require robust hot melting machines or thermal densifiers capable of continuous, high-capacity processing.

- Budget and ROI Analysis: While foam recycling machines require upfront capital investment, calculate total cost of ownership including disposal cost savings, potential revenue from recycled materials, and operational expenses. Most businesses achieve positive ROI within 2-3 years.

- Space and Infrastructure Requirements: Evaluate available floor space, electrical capacity, ventilation requirements, and material handling capabilities. Ensure your facility can accommodate the selected equipment and associated operational workflows.

- Regulatory Compliance Considerations: Review local environmental regulations, recycling mandates, and potential incentives or subsidies for recycling equipment investments. Some jurisdictions offer tax benefits or grants for sustainable waste management initiatives.

Industry Insight

The global foam recycling market is experiencing rapid growth, driven by stringent environmental regulations, corporate sustainability commitments, and technological advancements. Businesses that invest in foam recycling infrastructure today position themselves advantageously for future regulatory requirements while capturing immediate cost savings and revenue opportunities.

The Future of Foam Recycling: Emerging Trends and Technologies

The foam recycling industry continues evolving with innovations that enhance efficiency, reduce energy consumption, and expand material compatibility:

Advanced Automation: Next-generation machines incorporate AI-powered sensors and automated sorting systems that optimize processing parameters in real-time, maximizing output quality and minimizing energy consumption.

Chemical Recycling Integration: Emerging technologies combine mechanical recycling with chemical depolymerization processes, enabling recovery of virgin-quality polymers from foam waste—a breakthrough for closed-loop manufacturing systems.

Hybrid Processing Systems: Manufacturers are developing versatile machines that combine multiple processing technologies (compression, melting, and granulation) in single units, providing operational flexibility for businesses handling diverse foam waste streams.

Energy Recovery Capabilities: Advanced systems now capture and repurpose heat generated during thermal processing, significantly reducing net energy consumption and improving overall operational efficiency.

Conclusion: Strategic Investment in Sustainable Waste Management

Foam recycling machines represent a strategic investment for businesses seeking to enhance operational efficiency, reduce environmental impact, and meet evolving sustainability expectations. By understanding the distinct capabilities of different machine types—from cold compactors and hot melters to thermal densifiers and granulators—companies can select solutions optimally aligned with their specific operational requirements.

The benefits extend beyond immediate cost savings to encompass environmental stewardship, regulatory compliance, revenue generation, and enhanced market positioning. As regulatory pressure intensifies and consumer awareness grows, businesses implementing EPS recycling solutions today will enjoy competitive advantages tomorrow.

Ready to transform your foam waste management strategy? Evaluate your current waste streams, calculate potential cost savings, and explore foam recycling solutions that align with your operational goals and sustainability commitments.