EPS Recycling Machine

One page, two proven solutions for compacting EPS foam waste: a Hot Melt Densifier for highest density ingots, and a Hydraulic Compactor for low‑energy cold compaction. Explore both options below and choose what fits your throughput, power, and downstream needs.

EPS Foam Hot Melt Densifier

Transform bulky EPS foam waste into a valuable, compact commodity. Our hot melt densifier reduces foam volume by up to 90:1, drastically cutting your storage and transportation costs while creating a new revenue stream.

Get a Custom QuoteUnlock the Value in Your Foam Waste

Slash Waste Volume by 90:1

Dramatically reduce the storage space required for foam scrap and cut waste transportation costs significantly.

Create a New Revenue Stream

Convert worthless foam waste into dense, sellable EPS ingots, a valuable raw material for manufacturers.

Achieve Sustainability Goals

Divert thousands of cubic feet of foam from landfills, reduce your carbon footprint, and boost your green credentials.

From a Costly Problem to a Profitable Solution

The High Cost of EPS Waste

- Bulky foam fills dumpsters quickly, leading to exorbitant disposal and hauling fees.

- Valuable warehouse and floor space is consumed by piles of lightweight, low-value scrap.

- Negative environmental impact from sending non-biodegradable foam to landfills.

The Hot Melt Densifier Advantage

- A 90:1 compaction ratio means one truckload of ingots equals 90 truckloads of loose foam.

- Reclaim your floor space and generate income by selling the densified EPS blocks.

- Become a part of the circular economy by creating a reusable industrial commodity.

The 4-Step Transformation Process

1. Feeding

Loose EPS foam waste is fed into the machine's hopper, where a crusher breaks it into smaller, manageable pieces.

2. Melting

The crushed pieces are heated and melted at a controlled temperature, releasing the air and densifying the material.

3. Extruding

The molten polystyrene is then extruded through a die, forming a continuous, dense, and easy-to-handle ingot.

4. Cooling & Stacking

The hot ingots cool and solidify into hard blocks, which can be easily cut to length, stacked on pallets, and sold.

Disposal Costs vs. Profit Generation

| Factor | Traditional Disposal | EPS Hot Melt Densifier |

|---|---|---|

| Storage Space | Extremely High | Minimal (90x Reduction) |

| Transport Costs | Very High (Paying to haul air) | Very Low |

| Revenue | Negative (Paying for disposal) | Positive (Selling ingots) |

| Environmental Impact | Landfill Waste | Circular Economy |

Technical Specifications

| Model | EPS-RM-500 |

|---|---|

| Capacity | Up to 500 kg/hr (depending on EPS density) |

| Compression Ratio | 90:1 |

| Total Power Consumption | Approx. 18.5 kW (Crusher: 7.5 kW, Extruder: 11 kW) |

| Power Supply | 380V/50Hz/3Phase (customizable) |

| Dimensions (L*W*H) | Approx. 2500 x 1200 x 1800 mm |

| Weight | Approx. 1500 kg |

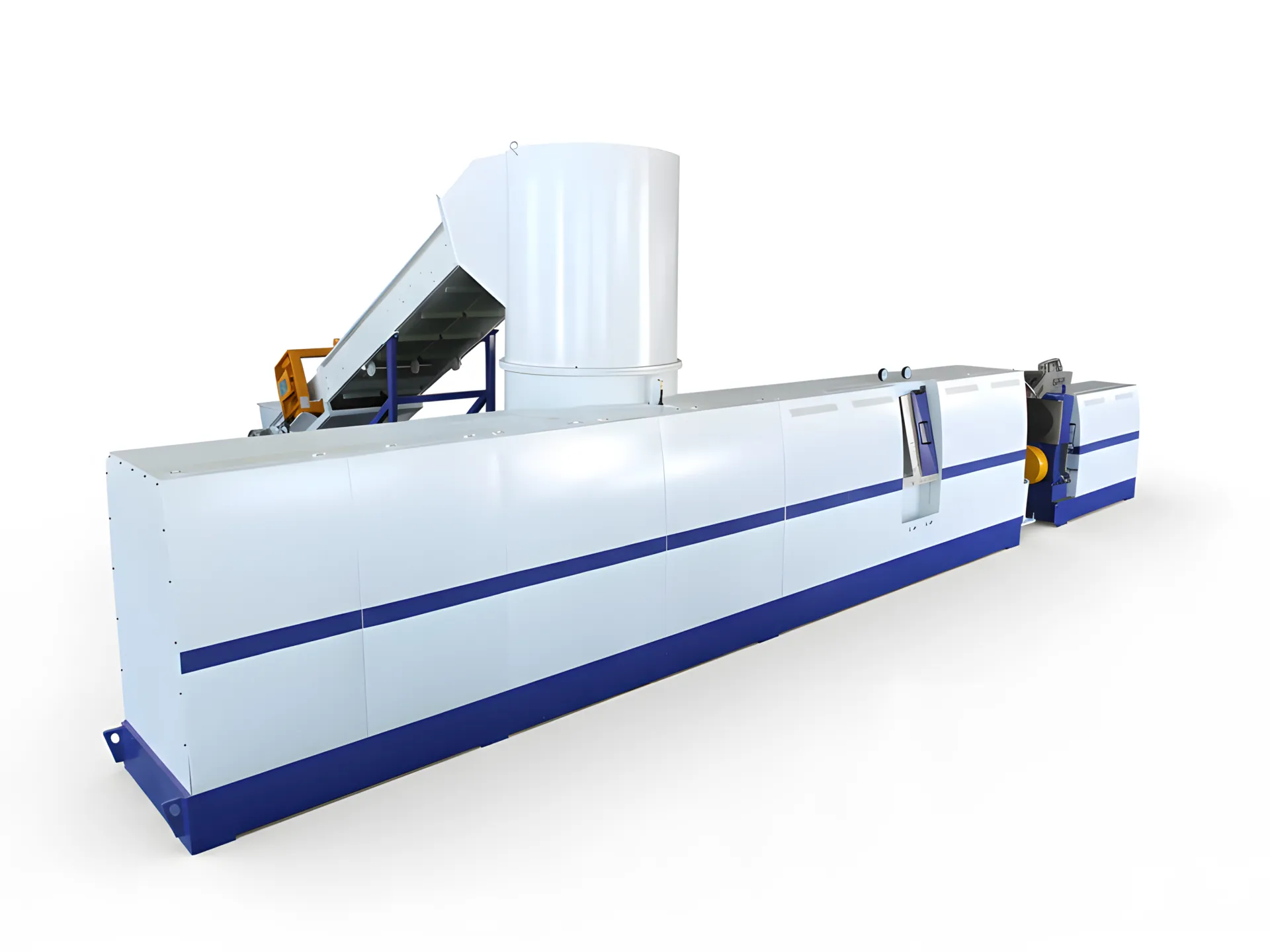

EPS Foam Hydraulic Compactor

A cold compaction solution for EPS foam. Compress loose foam into dense, stackable blocks — with lower energy use, no melting, and clean operation. Achieve up to 50:1 volume reduction to cut handling and freight costs.

Get a Custom QuoteWhy Choose Hydraulic Compaction

Up to 50:1 Reduction

Compress bulky EPS into uniform, high-density blocks that are easy to stack, store, and ship.

Lower Energy, No Melting

Cold compaction avoids melting, fumes, and thermal management — simplifying daily operation.

Robust & Easy to Maintain

Hydraulic system and heavy-duty frame deliver reliable performance with straightforward maintenance.

From Loose Foam to Dense Blocks

Operational Pain Points

- Foam occupies large storage areas and drives up logistics costs.

- Frequent dumpster hauls and tipping fees reduce margins.

- Manual handling increases mess and inefficiency.

The Hydraulic Compactor Advantage

- Cold compaction creates clean, manageable blocks without melting.

- Lower energy use and simple controls reduce operating cost.

- Uniform block size improves storage density and transport efficiency.

Simple 4-Step Process

1. Feeding

Loose EPS is fed into the hopper for pre-crushing.

2. Pre-crushing

Foam is shredded to consistent chip size for stable compaction.

3. Hydraulic Compaction

High-pressure ram compresses material into dense, uniform blocks.

4. Strapping & Stacking

Blocks are strapped or wrapped, then stacked on pallets for sale or shipment.

Disposal Costs vs. Hydraulic Compaction

| Factor | Traditional Disposal | EPS Hydraulic Compactor |

|---|---|---|

| Storage Space | Extremely High | Low (Up to 50x Reduction) |

| Transport Costs | Very High | Low |

| Revenue | Negative | Positive (Sell compacted blocks) |

| Operating Complexity | Manual, inefficient | Simple cold compaction |

Technical Specifications

| Model | EPS-HC-300 |

|---|---|

| Capacity | Up to 300 kg/hr (material & density dependent) |

| Compression Ratio | Up to 50:1 (cold compaction) |

| Total Power Consumption | Approx. 15 kW (Crusher: 7.5 kW, Compaction: 7.5 kW) |

| Power Supply | 380V/50Hz/3Phase (customizable) |

| Dimensions (L×W×H) | Approx. 2200 × 1100 × 1700 mm |

| Weight | Approx. 1300 kg |

See The Machines In Action

Equipment Gallery

What Our Clients Are Saying

We went from paying $1,000 a week in foam disposal fees to generating revenue. This machine fundamentally changed our waste management from a cost center to a profit center.

Warehouse Manager

The amount of warehouse space we've reclaimed is incredible. What used to be a mountain of foam scrap is now a single, neat pallet of ingots. Our facility has never been cleaner.

Logistics Coordinator

As a company committed to sustainability, this machine was a perfect fit. It's a reliable, effective solution that aligns with our environmental goals and also benefits our bottom line.

Sustainability Officer

Turn Foam Waste Into Profit

Contact our specialists today for a free consultation and a detailed quote based on your specific volume and needs.