In the competitive landscape of modern manufacturing, plastic recycling has evolved from an environmental obligation to a strategic economic driver. For plant managers and recycling facility operators, the profitability of this process hinges on one critical piece of equipment: the Industriezerkleinerer.

At Energycle, we understand that your shredder is not just a machine—it is the gatekeeper of your production line. If the shredder fails, the entire line stops. This guide explores the engineering behind processing diverse plastic materials and how choosing the right Kunststoffzerkleinerer can maximize your throughput, longevity, and Return on Investment (ROI).

The Material Challenge: Durability vs. Shredding Dynamics

Plastic is not a monolith; it is a complex family of polymers with distinct behaviors under stress. A “one-size-fits-all” approach to shredding often leads to equipment fatigue, jams, and inconsistent output.

Here is how we analyze the shredding requirements for the most common industrial plastics:

1. High-Density Polyethylene (HDPE) & Rigid Plastics

- Anwendungen: Chemical drums, piping, and crates.

- The Shredding Challenge: HDPE has a high strength-to-density ratio. It requires a shredder with high torque to shear through thick walls without stalling. Inconsistent shredding here can lead to bulk density issues in the washing line.

- Die Lösung: Heavy-duty rotors with aggressive knife geometries are essential to fracture these rigid structures efficiently.

2. Polyethylene Terephthalate (PET)

- Anwendungen: Beverage bottles and thermoformed packaging.

- The Shredding Challenge: PET is highly abrasive. Processing tons of dirty PET bottles daily acts like sandpaper on standard steel blades.

- Die Lösung: We recommend wear-resistant alloy blades and screens to maintain cutting precision and reduce maintenance downtime.

3. Polypropylene (PP) & Flexible Films (LDPE)

- Anwendungen: Woven bags, automotive parts, and packaging films.

- The Shredding Challenge: Flexible plastics (LDPE films) are notorious for wrapping around the rotor (“film winding”), causing friction and overheating.

- Die Lösung: Energycle shredders utilize specific anti-winding rotor designs and optimized cutting gaps to ensure clean shearing rather than tearing.

4. Polyvinylchlorid (PVC)

- Anwendungen: Window profiles and medical tubing.

- The Shredding Challenge: PVC is heat-sensitive. If a shredder runs at too high a speed, the friction heat can degrade the material, releasing corrosive chlorine gas and damaging both the plastic quality and the machine.

- Die Lösung: A low-speed, high-torque configuration is non-negotiable for PVC to keep processing temperatures low.

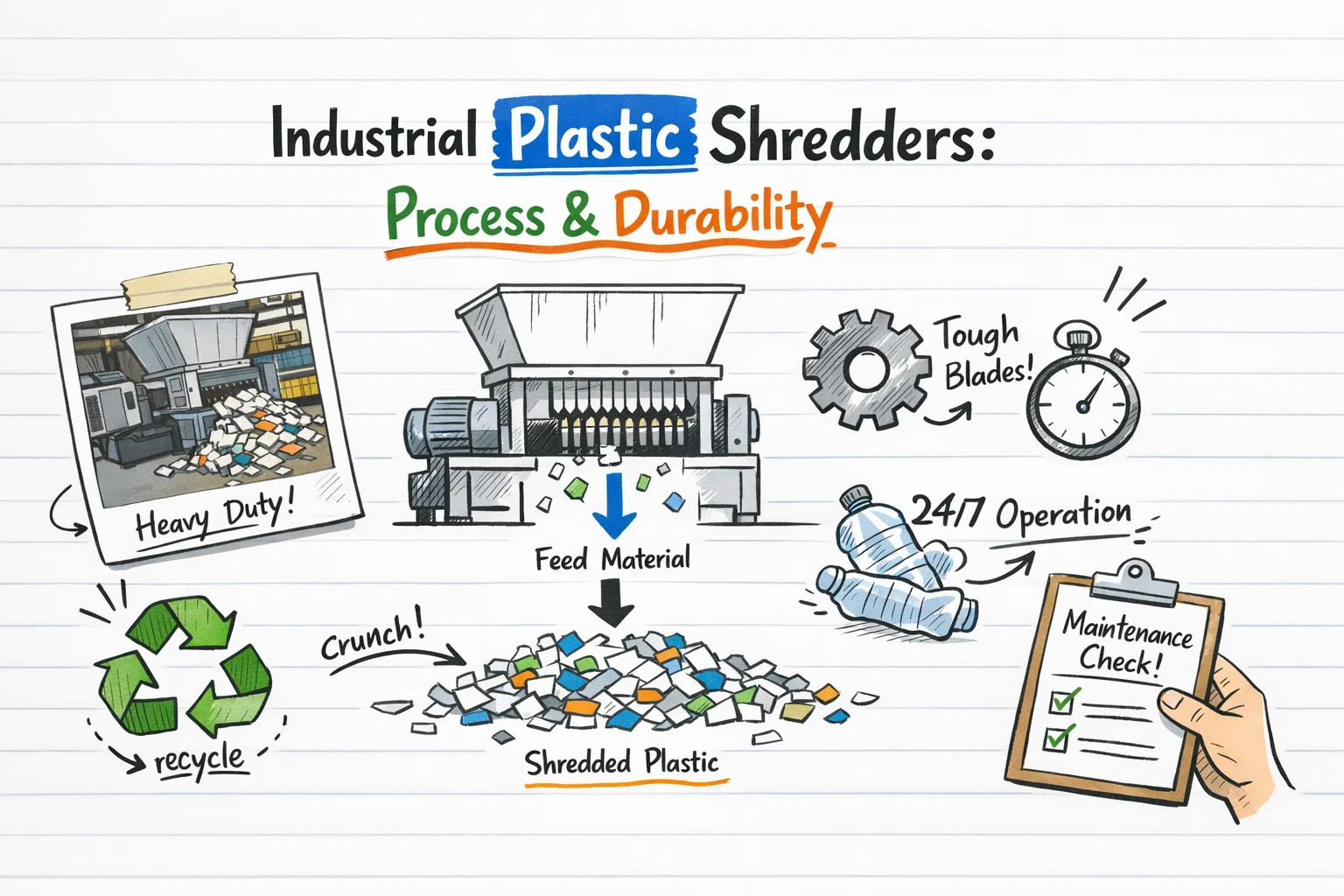

The Industrial Process: From Waste to Wealth

Understanding where the shredder fits into the larger ecosystem is vital for optimizing your plant layout.

Step 1: Intelligent Feeding and Sorting

Before the blades touch the material, efficiency begins with the feed. Whether utilizing a conveyor belt, forklift, or manual feed, the goal is a consistent flow. Modern lines often employ optical sorters pre-shredding to remove non-plastics, protecting the shredder’s cutting chamber from catastrophic damage caused by uncrushable metals.

Step 2: The Critical Shredding Phase

This is the heart of the operation. Material is fed into the cutting chamber where the rotor (equipped with rotating knives) shears the plastic against fixed counter-knives.

- Size Control: A screen beneath the rotor dictates the final particle size.

- Throughput Optimization: Energycle machines use “Smart Load Control” to automatically reverse the rotor if an overload is detected, preventing jams and protecting the motor.

Step 3: Contaminant Liberation

Shredding does more than just reduce size; it liberates contaminants. By fracturing the plastic, labels, dirt, and dried liquids are loosened, making the subsequent washing phase significantly more efficient. A clean cut in the shredder results in a cleaner flake in the washer.

Step 4: Washing and Separation

The shredded “flakes” or “regrind” move to friction washers and float-sink tanks. Because the shredder has produced a uniform particle size, the washing friction is applied evenly, ensuring high purity levels in the final output.

Step 5: Pelletizing (Compounding)

Finally, the clean, dry flakes are melted and extruded into pellets. This is where the quality of the shredding pays off: uniform flakes melt consistently, resulting in high-grade recycled pellets that command premium market prices.

Why Energycle? The Advantage of Engineering Excellence

When you invest in capital equipment, you are buying uptime. Energycle shredders are engineered to solve the most common pain points in the industry:

- Robuste Konstruktion: We build our chassis and rotors to withstand heavy shock loads. Our machines don’t just survive the factory floor; they dominate it.

- Maintenance-Friendly Design: We know that downtime kills profitability. Our “Easy-Access” split-chamber designs allow your maintenance team to rotate or change knives quickly, getting you back in production faster.

- Tailored Configurations: We don’t sell you a catalog number; we configure the rotor type, blade material, and drive system based on dein specific plastic stream (e.g., films vs. rigid blocks).

- Energieeffizienz: Our optimized drive systems deliver maximum cutting force with reduced power consumption, lowering your operational cost per ton.

Conclusion: Partnering for Sustainable Profit

The role of the industrial shredder extends far beyond simple size reduction. It is the foundational step that determines the quality of your end product and the efficiency of your entire recycling line.

At Energycle, we bridge the gap between heavy-duty engineering and sustainable processing. Whether you are upgrading an existing line or building a new facility, choosing the right equipment is the first step toward a profitable, sustainable future.

Ready to optimize your recycling capabilities?

Contact the Energycle team today to discuss your material requirements and discover how our high-performance shredding solutions can transform your waste management process.