Industrial Plastic Recycling Drying Systems

Achieve <3% Moisture • Increase Throughput • Maximize Value

Professional dewatering and drying solutions for washed plastic films and rigid flakes—designed to stabilize extrusion, improve pellet quality, and reduce operating costs.

Drying is the final quality gate before pelletizing

Most recycling lines remove bulk water mechanically (squeezer or centrifugal dryer) before final hot-air drying. Proper moisture control ensures stable extrusion and higher pellet value. If you are planning downstream extrusion, see Plastic Pelletizers.

Technology for Peak Performance

High-Efficiency Dewatering & Drying

Our systems are designed for continuous, heavy-duty operation, handling diverse plastic types and delivering industry-leading dryness to prepare materials for high-quality pelletizing.

Precise Moisture Control

Achieve final moisture content as low as 1-3% for films and under 2% for rigid flakes.

Mechanical & Thermal Solutions

From centrifugal force to thermal drying, we offer the right technology for your specific material and budget.

Advanced System Integration

Each machine is engineered to integrate seamlessly into existing washing lines, enhancing overall process efficiency and throughput.

Material Versatility

Optimized for a wide range of materials, including PE/PP films, PET flakes, and rigid HDPE/PP plastics.

Energy-Saving Designs

Mechanical dewatering systems offer a cost-effective alternative to thermal dryers, reducing operational costs.

Increased Throughput

By effectively removing water, our systems prevent production bottlenecks and boost the output of your entire line.

Improved Pellet Quality

Properly dried material eliminates defects in the final pellets, leading to a higher-value end product.

Explore Our Drying Systems

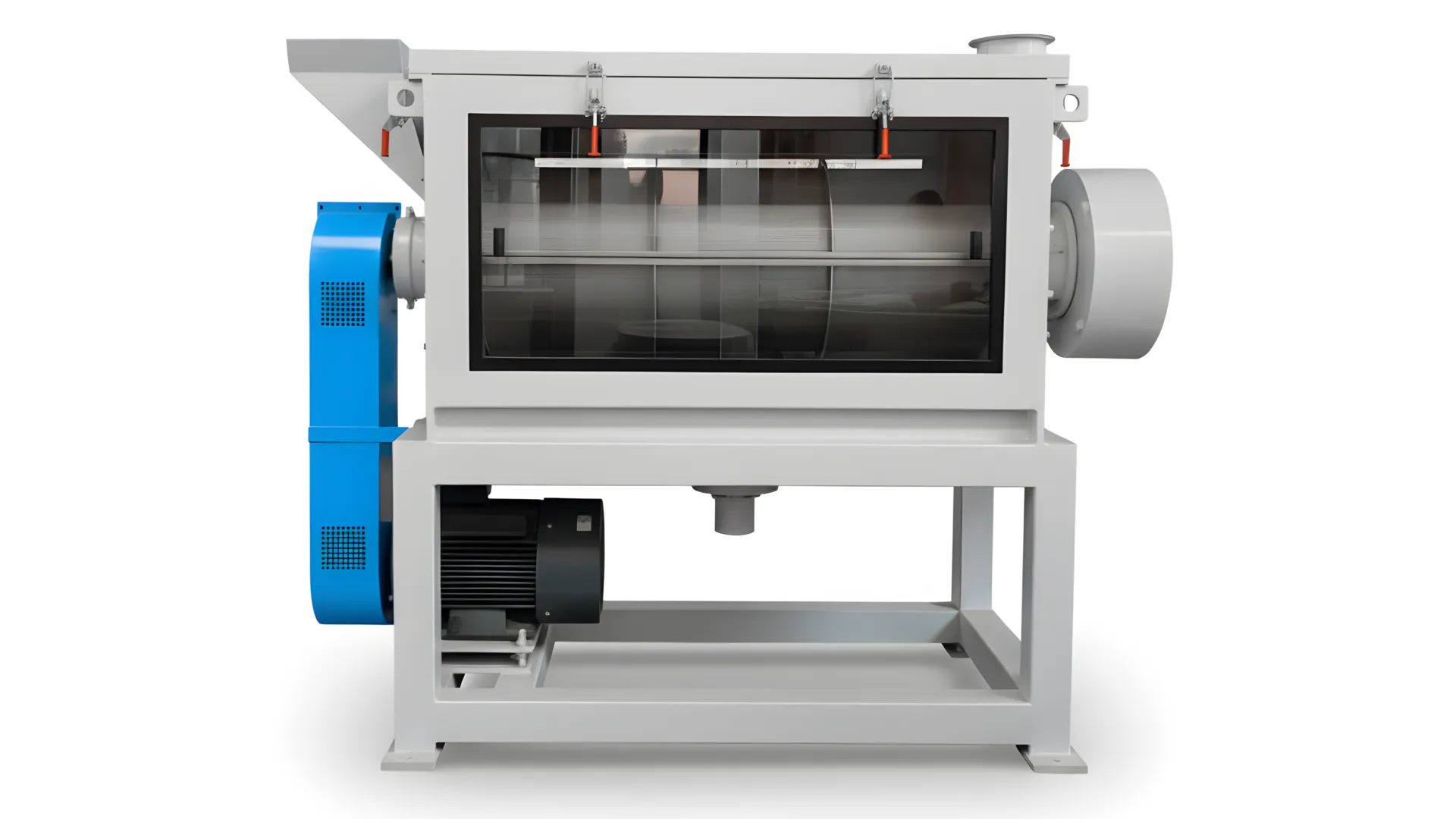

Plastic Film Squeezer & Densifier

The ultimate solution for dewatering and densifying washed films. It mechanically reduces moisture to 1-5% and transforms bulky material into dense, easy-to-feed lumps.

Centrifugal Dryer for Rigid Flakes

A high-speed, energy-efficient machine that rapidly reduces moisture in rigid flakes (PET, PP, PE) to under 2% using powerful centrifugal force for a final rinse and dry.

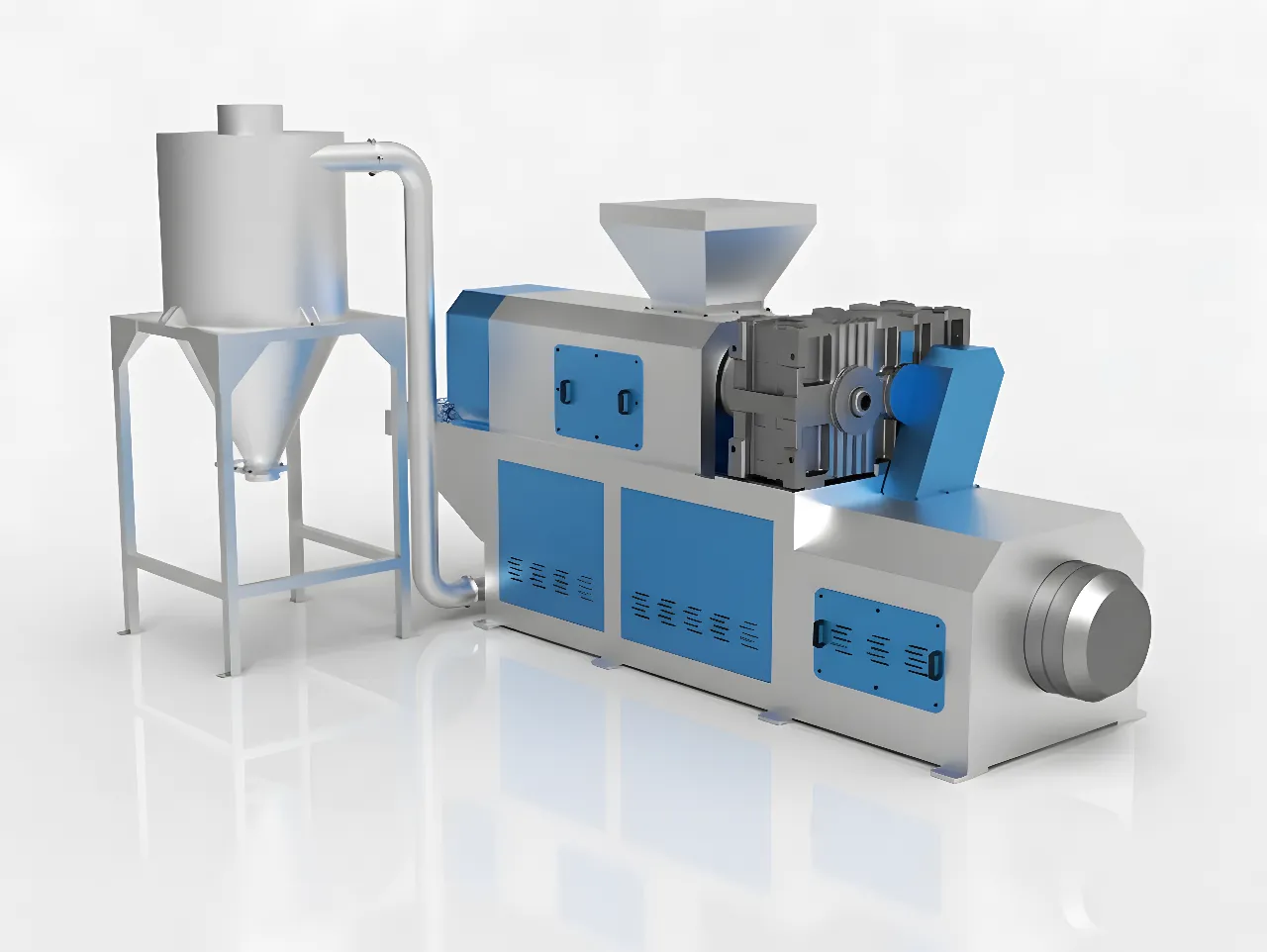

Thermal Dryer for Plastic Recycling

A high-efficiency solution for film and PET lines. Using hot air and a cyclone separator, it effectively reduces moisture content to under 3% for clean, dry output.

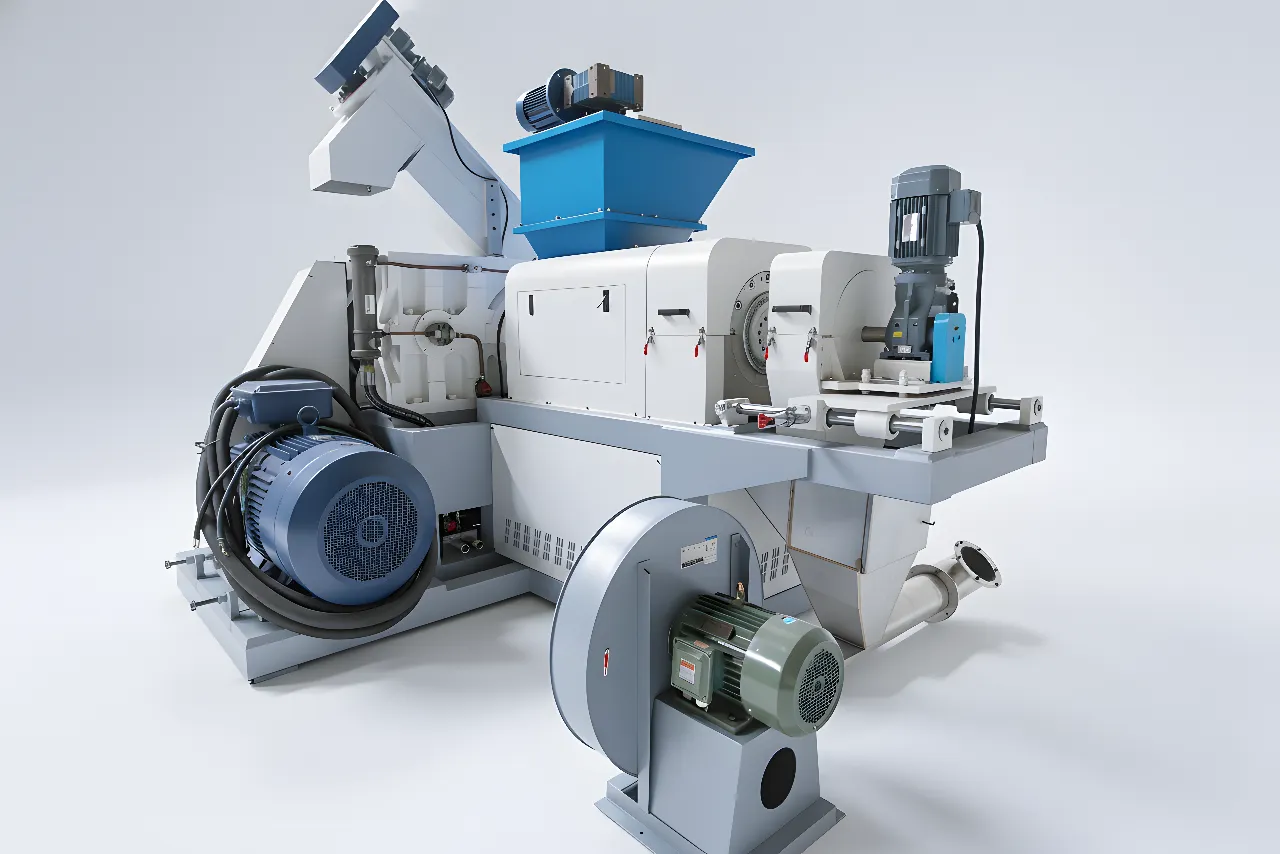

Screw Press Dewatering System

Engineered for PE film washing lines, this machine efficiently extracts moisture to below 15%, offering a cost-effective alternative to thermal dryers.

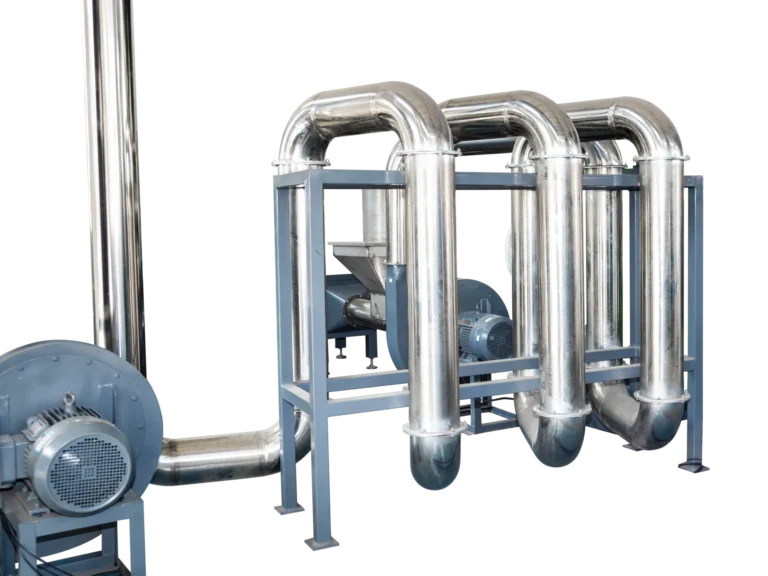

Pipeline Hot Air Drying System

A heavy-duty system for rigid plastics (PET, HDPE, PP) that guarantees a final moisture content of less than 2%, boosting throughput and material value.

High-Speed Friction Washer

Efficiently removes moisture from various plastic materials, enhancing product quality, increasing processing efficiency, and providing energy savings.

Quantifiable Benefits

Higher Material Value

Premium pricing with consistently low moisture content.

Lower Operating Costs

Mechanical dewatering saves significant energy costs vs. thermal drying.

Increased Production Rates

Boost throughput by preventing bottlenecks in your washing line.

Fewer Downstream Defects

Eliminate moisture-induced issues in extrusion and molding processes.

Frequently Asked Questions

What is the difference between mechanical and thermal drying?

Mechanical dewatering (like a squeezer or centrifugal dryer) uses physical force to remove the bulk of water—it's highly energy-efficient. Thermal drying uses heated air to evaporate the remaining moisture for the lowest possible levels, which is critical for materials like PET.

Which drying system is right for my plastic material?

It depends on your material and target moisture. For soft PE/PP films, a Film Squeezer is often the best all-in-one solution. For rigid flakes like PET that require very low moisture, a combination of a Centrifugal Dryer followed by a Pipeline Hot Air System is ideal.

What final moisture level can I expect?

Our systems are designed for top performance. You can expect moisture levels of 1-5% for films processed with a squeezer, and under 2% for rigid flakes processed with our advanced centrifugal and thermal systems, ensuring your material is ready for high-quality pelletizing.

Can you design a complete washing, drying, and pelletizing line?

Yes. We design turnkey recycling systems based on your material, contamination level, target moisture, and output. Drying equipment is selected as part of the complete line to ensure stable extrusion and consistent pellet quality.

Ready to Optimize Your Drying Process?

Contact our experts to discuss your material type, target moisture level, and throughput requirements. We’ll recommend the most efficient drying configuration and provide a competitive quote. For turnkey projects from washing to pelletizing, start with Recycling Solutions.

Request a Free Proposal