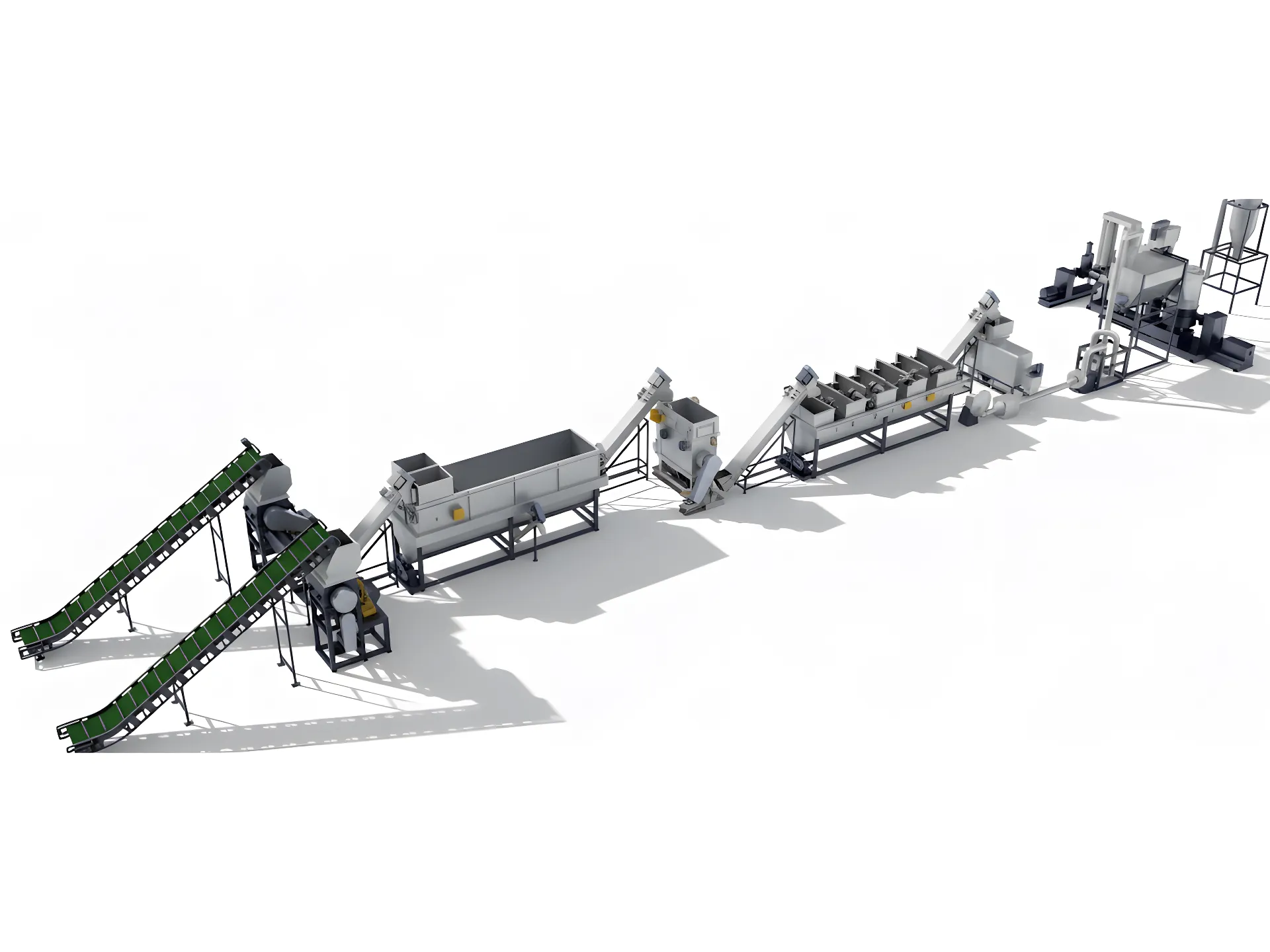

Línea de lavado para trituración y densificación de películas de plástico PP/PE

Desde pacas hasta pellets/copos limpios y densos. Procesamiento de 200 a 1000 kg/h con humedad estable y alta densidad aparente, diseñado para películas muy contaminadas.

Por qué esta línea sobresale

El proceso integrado y los módulos configurables proporcionan un resultado limpio y denso, adecuado para el transporte y el procesamiento posterior.

Eficiencia de extremo a extremo

Flujo continuo desde la trituración de pacas hasta la salida densificada, minimizando la manipulación y el tiempo de inactividad.

Alta densidad aparente

Alcanza aproximadamente 350–410 kg/m³ con humedad estable para facilitar el transporte y la alimentación.

Listo para la contaminación

La granulación húmeda y la separación por hundimiento/flotación eliminan barro, piedras, papel y etiquetas livianas.

Flujo del proceso

Trituración de pacas

La trituradora de un solo eje abre pacas de película PP/PE compactadas y las reduce en trozos manejables.

Granulación húmeda

El granulador húmedo de alta velocidad corta en copos uniformes mientras realiza el prelavado y el tamizado por tamaño.

Separación hundimiento/flotación

La separación por densidad elimina los contaminantes pesados; la película flotante se recoge para secarla y densificarla.

Apretar y densificar

Potente exprimidor-densificador que deshidrata y compacta la película en copos/pellets densos ideales para la alimentación.

Aplicaciones

Tipos de materiales

Bolsas tejidas de PP, película de PE, película de embalaje de LDPE/LLDPE, película agrícola (después de la preclasificación), película estirable.

Uso de salida

Alimentación de extrusoras/peletizadoras, líneas de lavado, aglomeradoras o venta directa como copos densificados.

Contaminación

Maneja suciedad, papel, etiquetas y humedad con lavado y separación en múltiples etapas.

Especificaciones técnicas

| Opciones de rendimiento | 200–300 kg/h · 500–700 kg/h · hasta 1000 kg/h |

|---|---|

| Formulario de salida | Copos densificados / pellets irregulares |

| Densidad aparente | Aprox. 350–410 kg/m³ |

| Humedad final | Típicamente ≤ 3–5% (dependiente del material) |

| Demanda de energía | Aprox. 120–350 kW dependiendo de la configuración |

| Sistema de agua | Circuito cerrado con filtración y DAF opcional |

| Controles | PLC con HMI; enclavamientos de seguridad y protección contra sobrecarga |

| Huella | Disposición modular y configurable para adaptarse al espacio de la planta. |

Qué está incluido

Desfibradora + Transportador

Trituradora de un solo eje con empujador hidráulico y cuchillas resistentes al desgaste.

Granulador húmedo

Corte de alta velocidad, pantalla integrada, descarga de agua para prelavado.

Tanque de hundimiento/flotación

Separación de densidad efectiva con desnatado y descarga de lodos.

Arandela de fricción

Limpieza intensiva opcional y eliminación de suciedad superficial.

Exprimidor-Densificador

Prensado y compactación de tornillo para reducción de humedad y densidad aparente.

Electricidad y tuberías

Controles PLC, enclavamientos, plomería de circuito de agua y orientación sobre instalación.

Preguntas frecuentes

¿Qué capacidad debo elegir?

Seleccione según el volumen de pacas entrantes, la contaminación y la dotación de personal. Líneas modulares de 200 a 1000 kg/h con opciones de actualización.

¿Qué tan limpio es el resultado final?

Con granulación húmeda, hundimiento/flotación y lavado por fricción/caliente opcional, puede alcanzar una humedad de ≤ 3–5% y niveles bajos de impurezas adecuados para la peletización.

¿Puede manejar película agrícola?

Sí, con preclasificación y módulos opcionales (captura piedras, lavado en caliente). Las películas muy sucias pueden reducir ligeramente el rendimiento.

¿Ofrecen instalación y capacitación?

Sí. Ofrecemos diseño de distribución, soporte para la puesta en marcha y capacitación de operadores con opciones remotas o in situ.

Obtenga una cotización

Indíquenos los tipos de material, el nivel de contaminación y el rendimiento deseado. Le diseñaremos una solución y un plano de diseño a medida.