Expanded Polystyrene (EPS/Styrofoam) is mostly air by volume, so logistics often dominate the economics: a 53-foot trailer full of loose EPS can be volume-limited long before it is weight-limited. In many scenarios, recycling becomes financially viable only after densification. This guide compares three common solutions: Shredding, Cold Compaction, and Thermal Densification.

Related equipment: single shaft shredder.

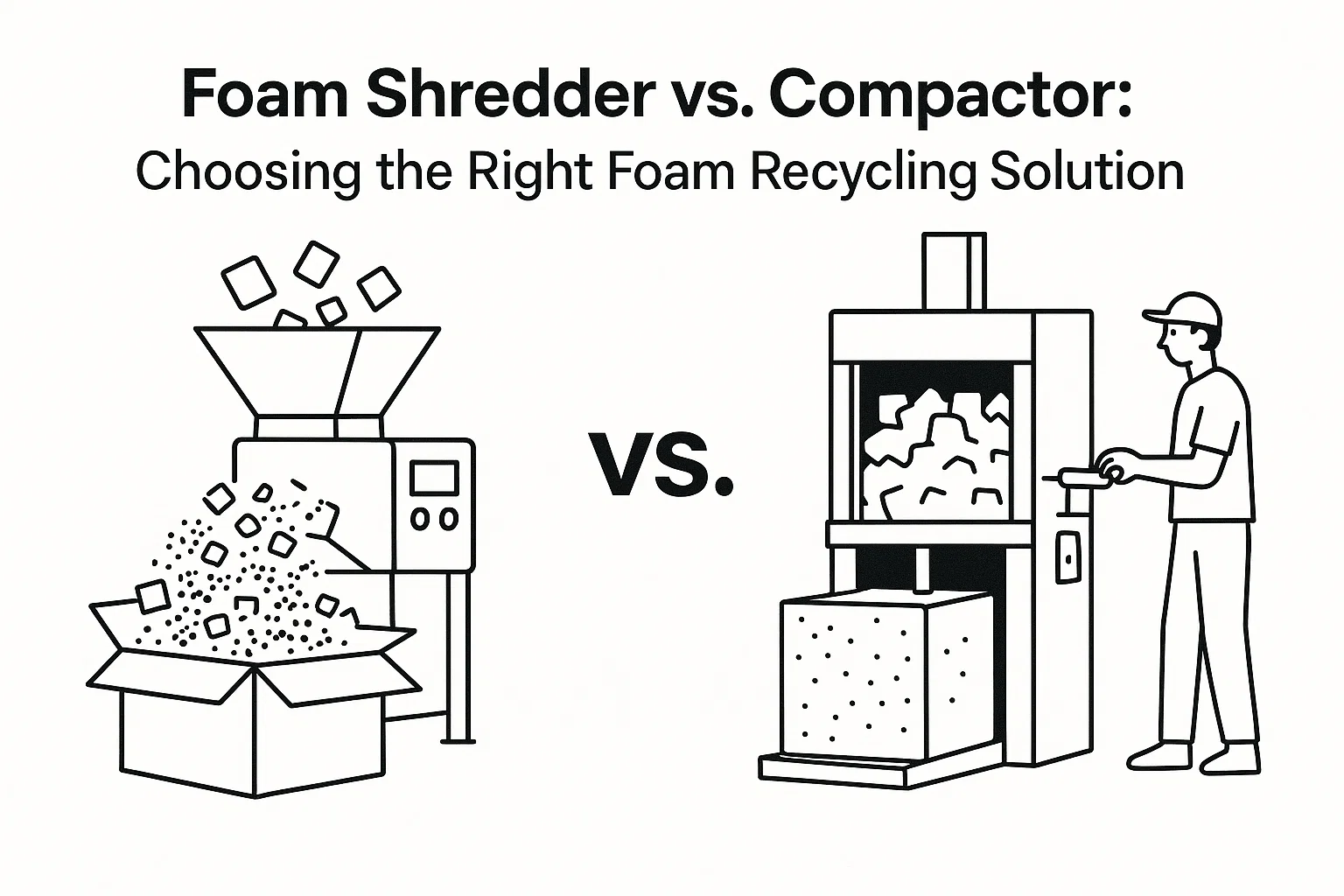

1. The Foam Shredder (Volume Reduction Ratio: 3:1)

A foam shredder tears bulky packaging into 20-50mm flakes. It does not compress the material; it simply breaks the structure.

- Best For: Manufacturers who reuse foam in-house (e.g., as “bean bag” filler or mixed into lightweight concrete).

- Logistics Check: If you plan to ship the waste to a recycler, shredding is insufficient. You are still shipping mostly air, and freight costs will exceed the scrap value.

- Mechanism: Low-speed, high-torque shafts with “ripping” teeth.

2. The Cold Compactor (Ratio: 50:1)

Also known as a Screw Press, this machine physically squeezes the air out of the EPS.

- Mechanism: An auger screw pushes the foam flakes against a restricted gate. The friction and pressure fuse the beads into a solid “log” without melting them.

- Output: White, dense logs (300-400 kg/m³).

- Energy: Low (Electromechanical only).

- Best For: Fish boxes (wet EPS), Electronics packaging.

- Advantage: It does not degrade the polymer chains. The resulting logs can be easily re-ground and molded into new PS products.

3. The Thermal Densifier (Ratio: 90:1)

A “Melter” uses heat to liquefy the foam, removing almost all of the trapped air.

- Mechanism: Electric heaters or intense friction melt the EPS into a toothpaste-like consistency, which is extruded into an ingot.

- Output: Rock-hard “purged” ingots (600-700 kg/m³) that look like hard plastic.

- Energy: High (Heating elements).

- Best For: Mixed dirty foam, High-volume logistics.

- Advantage: Maximum truck weight. You can load 20 tons of densified ingots into a container, maximizing export value.

Comparison Matrix

| Metric | Shredder | Cold Compactor | Thermal Densifier |

|---|---|---|---|

| Reduction Ratio | 3:1 | 50:1 | 90:1 |

| Output Density | 10-20 kg/m³ | 250-400 kg/m³ | 600-700 kg/m³ |

| Energy Cost | Low | Medium | High |

| Odor/Fumes | None | None | Styrene Gas (Vent required) |

| Freight Viability | Poor | Good | Excellent |

Financial Analysis: The “Pay-Weight” Threshold

To sell recycled EPS (rEPS), you generally need a full truckload.

* Loose Foam: A 53′ truck holds ~1,000 lbs. Value = $0 (Cost to ship > Value of material).

* Cold Compacted: A 53′ truck holds ~35,000 lbs. Value = Profitable.

* Thermal Densified: A 53′ truck holds ~45,000+ lbs. Value = More profitable.

Recommendation:

* If you generate < 1 ton/month: Use a Shredder and reuse locally.

* If you generate > 5 tons/month: Invest in a Cold Compactor.

* If you generate > 20 tons/month or export: Invest in a Thermal Densifier.

FAQ

Can I run wet fish boxes in a thermal densifier?

No. The water turns to steam, causing dangerous “blowback” and voids in the ingot. Use a Cold Compactor (like the Energycle CP Series) or a specialized washer-dryer system first.

Does cold compaction degrade the plastic?

No. Cold compaction preserves the Molecular Weight (MW) of the polystyrene better than thermal densification, which adds “heat history.”

References

[1] “EPS Recycling Logistics,” Expanded Polystyrene Industry Alliance. EPS Recycling Logistics

[2] “Densification Technologies for Polymers,” Waste Management Journal. Densification Technologies for Polymers