High-Recovery Eddy Current Separator for Fine Metals

Engineered with a high-frequency concentric rotor, our Eddy Current Separator (ECS) excels at recovering valuable non-ferrous particles as small as 2mm from PET flakes, glass, incinerator bottom ash (IBA), and more.

Maximize Purity and Profit

Unlock the hidden value in your waste streams. Our ECS technology is designed to deliver superior separation efficiency, ensuring higher purity rates for your recycled materials and maximizing your return on investment.

Precision Fine Particle Recovery

Don't let valuable micro-metals slip through. Our system is specifically optimized to identify and eject non-ferrous metal fragments down to 2mm, making it perfect for purifying PET plastic flakes and fine-fraction materials.

High-Intensity Magnetic Field

The concentric rotor, packed with high-performance Rare Earth magnets and spinning at up to 4000 RPM, generates an extremely powerful magnetic field, ensuring maximum repulsive force and superior separation of non-ferrous metals.

Robust & Industrial-Ready

Designed for demanding recycling environments, our ECS features ABB® or SEW® motors, a maintenance-free drum motor, wear-resistant components, and an easy-to-maintain cantilever frame design for quick belt changes.

Typical Applications

A crucial component for purification and metal recovery across a wide range of recycling industries.

PET Plastic Flakes

Removes fine aluminum and other non-ferrous contaminants to produce high-purity, food-grade rPET.

Incinerator Bottom Ash (IBA)

Efficiently recovers valuable non-ferrous metals from the fine fraction of processed bottom ash.

Glass Recycling

Purifies crushed glass (cullet) by removing non-ferrous metal caps and foils before melting.

ZORBA Upgrading

Enhances the quality and purity of your ZORBA (shredded non-ferrous scrap) by separating aluminum from heavy metals.

E-Waste (WEEE)

Recovers fine precious and non-ferrous metals from shredded electronic circuit boards and components.

Foundry Residues

Purifies casting sand and recycles non-ferrous residues from metal casting and foundry operations.

Engineered for Maximum Efficiency

High-Frequency Rotor

High-performance NdFeB rare earth magnets deliver a powerful 4500Gs surface strength at speeds up to 4000 RPM.

Uniform Vibratory Feeder

Optional vibratory feeder ensures a uniform, single-layer spread of material across the belt for optimal separation performance.

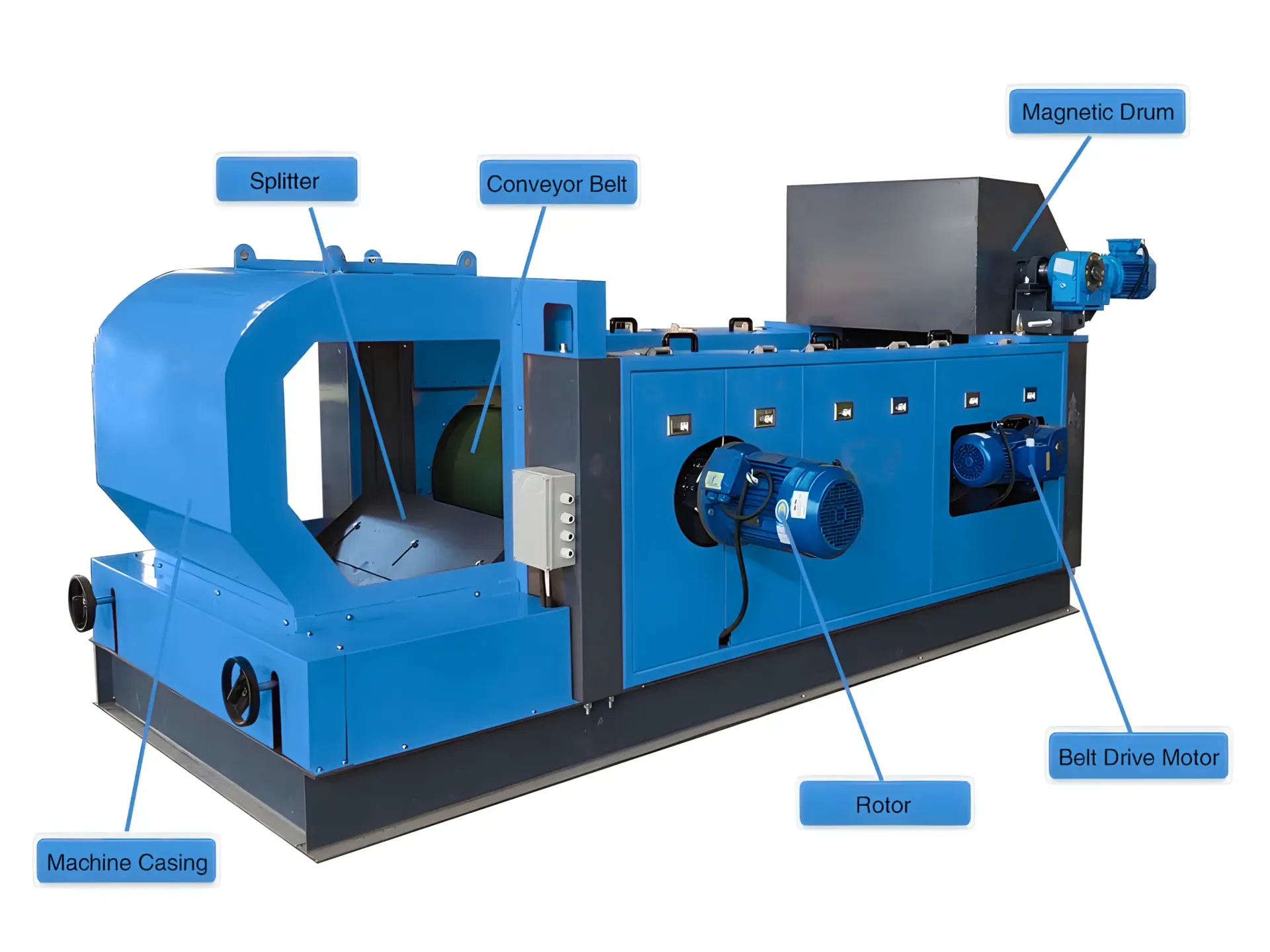

Adjustable Splitter Plate

Precisely tune the separation point with a manually adjustable splitter (angle, height, distance) for flawless recovery.

Quick-Change Belt System

The cantilever frame design allows for full conveyor belt replacement in just 10 minutes, minimizing downtime.

Technical Specifications

| Model | Dimensions (L×W×H) mm | Effective Belt Width | Rotor Speed (RPM) | Belt Speed (m/s) | Drive Power (kW) |

|---|---|---|---|---|---|

| 40A | 2080×1357×1100 | 330 mm | 0-3000 | 0-2 | 0.75 |

| 65A | 3300×1500×1200 | 520 mm | 0-4000 | 0-2 | 1.5 |

| 80A | 3300×1700×1200 | 670 mm | 0-4000 | 0-2 | 2.2 |

| 100A | 3300×1900×1200 | 840 mm | 0-4000 | 0-2 | 2.2 |

| 120A | 3300×2000×1200 | 1040 mm | 0-4000 | 0-2 | 2.2 |

| 140A | 3300×2130×1587 | 1200 mm | 0-4000 | 0-2 | 2.2 |

Frequently Asked Questions

What is the difference between a concentric and eccentric ECS?

A concentric rotor (like this model) has magnets across its full width, creating a powerful and uniform magnetic field ideal for separating small non-ferrous particles from non-metallic materials. An eccentric rotor has its magnetic pole offset, which helps prevent ferrous metals from sticking to the drum, making it better suited for applications with heavy ferrous contamination like scrap metal yards (ZORBA).

What is the smallest particle size this machine can separate?

Thanks to its high-frequency concentric magnetic rotor, this separator is expertly engineered to recover non-ferrous metal particles as small as 2mm, making it one of the most effective solutions on the market for fine fraction recovery.

Do I need a magnetic separator before the Eddy Current Separator?

Yes, it is highly recommended. Ferrous metals can stick to the magnetic rotor and cause damage or reduce separation efficiency. We offer optional integrated high-intensity drum magnets or magnetic head pulleys to remove any ferrous contaminants before the material reaches the ECS rotor, protecting your investment.

Get a Quote for Your Separation Needs

Contact our technical specialists to discuss your specific material and throughput requirements. We will help you configure the perfect Eddy Current Separator to maximize the purity and value of your recycled products.