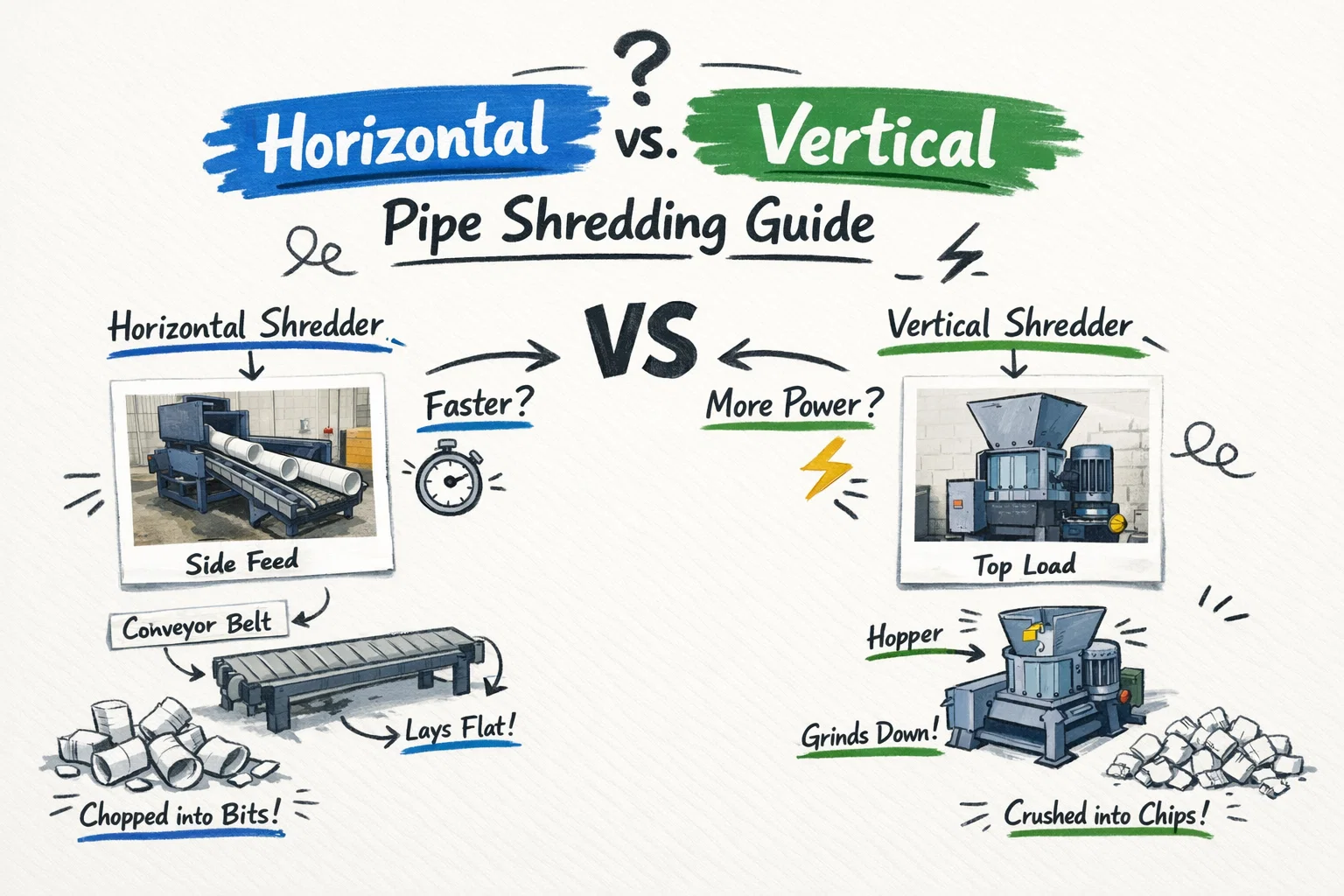

If you are trying to decide between a horizontal pipe shredder e un vertical pipe granulator, the real question is not “Which machine is better?” The question is which feeding method fits your material and workflow.

Long, thick, flexible pipes behave differently from rigid, brittle extrusions. Heavy pipes create different safety risks than light profiles. And a line that is short on labor needs a different feeding strategy than a plant that can dedicate people to pre-cutting.

This guide breaks down horizontal vs vertical pipe shredding using practical shop-floor criteria: material type, pipe diameter and length, contamination, labor, safety, and the output size you need for the next step.

Quick definitions (so we are comparing the right things)

- Horizontal pipe shredding (pipe tearing / pipe crusher): long pipes are loaded into a wide horizontal trough, then pushed into the rotor by a hydraulic ram.

- Vertical pipe granulation: long pipes and profiles drop into a vertical hopper and are fed by a hydraulic pusher into a granulator rotor for controlled cutting and regrind.

On Energycle, these two approaches map well to:

- Large diameter HDPE pipe tearing machine: Frantoio per tubi in HDPE di grande diametro

- Long PVC pipe and profile granulation: Granulatore verticale per tubi in PVC e profili per finestre

What the feeding method changes

Feeding is not a small detail. It affects almost everything you care about:

- Sicurezza: how much manual handling is needed, and whether the material can tip, roll, or whip.

- Throughput stability: whether long pieces bridge and jam, or feed smoothly under controlled force.

- Manodopera: whether you can eliminate pre-cutting, and how many operators must stay near the infeed.

- Output consistency: whether you get coarse chips for a shred-wash-extrude line, or uniform regrind for reuse.

Horizontal feeding: where it wins

Horizontal feeding is usually the most practical choice when the pipe is too large, too heavy, or too flexible to behave well in a vertical infeed.

- Large diameter HDPE and PE pipes

- Thick-walled pipe scrap

- Mixed long pipe sections and bundled offcuts

HDPE is tough and ductile. It tends to deform instead of snapping cleanly, especially in thick sections. A horizontal layout with a hydraulic pusher helps the rotor bite consistently instead of relying on gravity.

- No pre-cutting for oversized pipe: a wide horizontal chamber can accept whole pipes directly.

- Stable grip and tearing: the hydraulic ram keeps constant pressure so the rotor does not “polish” the surface.

- Safer handling for heavy pipes: forklifts or cranes can place pipe into the trough without lifting it vertically.

Energycle’s large diameter machine is designed specifically for this workload, including hydraulic feeding and screen-controlled discharge for a defined chip size.[1]

Horizontal tearing machines commonly produce chips, not fine regrind. If your next step is washing, sink-float separation, or a secondary granulator, coarse chips can be exactly what you want.

Vertical feeding: where it wins

Vertical feeding is often the better solution when the scrap is long but rigid, and you want controlled cutting with consistent regrind, without spending hours pre-cutting.

- Rigid PVC pipes

- Vinyl window and door profiles

- Other rigid extruded profiles with awkward shapes

PVC behaves differently than HDPE. It is more rigid and typically cuts cleanly in a granulator-style geometry, especially when the feeding is controlled.

- Direct vertical infeed for full-length pipes: reduces pre-cutting labor for long pipes and profiles.[2]

- Lower jamming risk with long parts: the feeding path is designed around length.

- More uniform regrind: screen sizing produces consistent downstream feedstock for re-extrusion or compounding.

Energycle’s vertical granulator design emphasizes hydraulic-assisted feeding, a V-cut rotor, and wear-resistant blades to keep output stable.[2]

Selection rules you can use on a real line

Use these rules when you are making a purchase decision or reconfiguring a pipe recycling cell.

If you are handling very large diameters and thick walls, horizontal loading is usually safer and more controllable. It reduces risky manual cutting and avoids lifting heavy pipe into a vertical position.[1]

For rigid PVC and vinyl profiles, a vertical granulator is built to accept long pieces directly and granulate into usable regrind, often with fewer handling steps.[2]

If your process is “tear → wash → secondary size reduction,” a tearing machine that outputs 40–120 mm chips can make sense as the first stage, because it simplifies feeding and protects downstream equipment from long pieces.[1]

If you are sending material back to extrusion, consistent particle size matters for feeding, melting stability, and filtration. A granulator-style system with a screen typically produces a more uniform output.[2]

Practical checklist: what to measure before you choose

Before you request a quote, gather these inputs. They determine whether horizontal or vertical feeding will run smoothly.

- Material: HDPE, PE, PVC, vinyl, or mixed

- Pipe outside diameter range and maximum diameter

- Wall thickness range (thin-wall vs thick-wall matters)

- Length range (including worst-case long pieces)

- Shape: round pipe, corrugated pipe, bundled scrap, profiles

- Contamination: sand, metal inserts, dirt, moisture

- Target output size: chips for washing, or regrind for extrusion

- Throughput target in kg/h

- Handling method: forklift, crane, manual

- Labor constraints: whether you must remove pre-cutting

Energycle calls out these same factors when recommending configurations, especially diameter, length, contamination level, and target output size.[2][1]

Common mistakes that cause jams (and how feeding method prevents them)

- Trying to granulate huge HDPE pipe in one step: HDPE can deform and “fight the cut.” A tearing stage with hydraulic pressure often stabilizes size reduction.

- Underestimating length: long pipes bridge easily in the wrong hopper geometry. Machines designed around long infeed reduce bridging.

- Ignoring contamination: sand and metal inserts accelerate blade wear. Basic inspection or magnetic separation can protect knives and screens.[1]

When a two-stage system is the smartest choice

Many facilities get the best results with two stages:

- Stage 1: Horizontal tearing for large diameter HDPE, producing stable chips

- Stage 2: Secondary granulation to reach final regrind size

This approach is especially useful when the incoming scrap includes long pieces, thick walls, and mixed lengths that are hard to feed consistently.

Domande frequenti

For very large, heavy pipes, horizontal loading can reduce risky manual cutting and awkward lifting. For long but lighter rigid pipes and profiles, vertical infeed can reduce manual handling by allowing direct feeding of full-length pieces.[1][2]

Some shredders can process multiple plastics, but performance and output quality depend on pipe size, wall thickness, and your throughput target. Energycle notes PVC can be processed on the HDPE pipe tearing machine, but also points to dedicated PVC granulation for high-throughput PVC recycling.[1]

Both approaches can use screens to define discharge size. Energycle specifies typical chip sizing via screen for the large diameter HDPE pipe machine and screen sizing for uniform output on the vertical granulator.[1][2]