Sblocca l'efficienza nel riciclaggio della plastica

Presentazione della macchina deballatrice verticale: la soluzione automatizzata per scomporre senza sforzo le balle di plastica compattate e potenziare la linea di riciclaggio.

Perché scegliere la nostra deballatrice verticale?

⚡

Efficienza senza pari

Automatizza il processo di sballatura, riducendo drasticamente il lavoro manuale e i tempi di preparazione.

📈

Maggiore produttività

Gestisce più balle contemporaneamente per una lavorazione continua e ad alto volume.

💲

Risparmi significativi sui costi

Riduce al minimo le spese operative riducendo il fabbisogno di manodopera e semplificando il flusso di lavoro.

Dalla balla alla bottiglia in 4 semplici passaggi

Balle di carico

Utilizzare un carrello elevatore per posizionare fino a cinque balle sul nastro trasportatore di alimentazione.

Cinghie tagliate

Tagliare in modo rapido e sicuro i fili o le cinghie che fissano ogni balla.

Debaling automatizzato

I doppi rotori controrotanti frantumano con precisione la plastica compattata.

Uscita continua

I materiali sfusi scorrono sul trasportatore successivo, pronti per il riciclaggio.

Progettato per le prestazioni

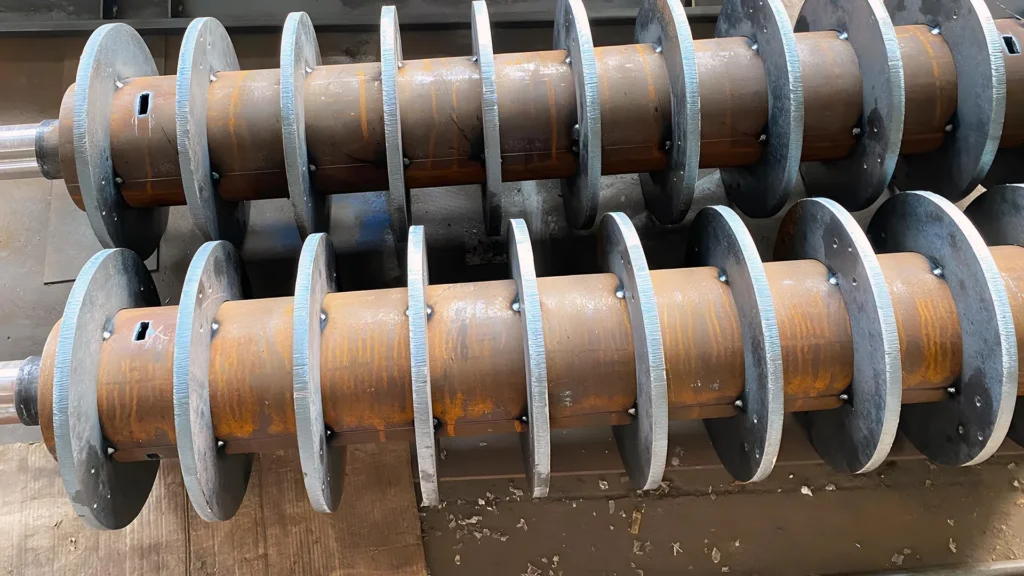

Doppi rotori controrotanti

Il cuore della macchina, progettato per la massima forza di frenata e la massima efficienza.

Specifiche tecniche

| Caratteristica | Specificazione |

| Potenza del motore principale | 7,5 kW x 2 (totale 15 kW) |

| Dimensione dell'alimentatore | 1550 mm x 1850 mm |

| Materiali applicabili | HDPE compattato, bottiglie in PET e altre plastiche rigide |

| Certificazione | Certificato CE |

| Personalizzazione | Modelli più potenti e più grandi disponibili su richiesta |

Applicazioni versatili e output di alta qualità

Ottieni una soluzione e un preventivo personalizzati

Pronti a rivoluzionare le vostre attività di riciclo? Compilate il modulo sottostante e i nostri esperti vi contatteranno per discutere le vostre esigenze specifiche.

Domande frequenti

Qual è la funzione principale della macchina deballatrice verticale?

La funzione principale è quella di rompere automaticamente balle compattate di plastica rigida come bottiglie in PET e HDPE, preparandole per la fase successiva del processo di riciclaggio, come la selezione, il lavaggio o la triturazione.

Questa macchina può gestire balle di pellicola di plastica?

No, questa macchina è progettata specificamente per la plastica rigida. La pellicola di plastica può avvolgersi attorno ai rotori e danneggiarli. Per le balle di pellicola di plastica, consigliamo un trituratore o un rompiballe specifico.

Qual è la capacità di produzione?

La produttività dipende dal modello e dalla densità delle balle. Il nostro modello standard può processare diverse tonnellate all'ora. Possiamo fornire dati esatti in base al materiale specifico e alle dimensioni delle balle.

Quanto lavoro manuale è richiesto?

Il lavoro manuale è minimo. È necessario un operatore per caricare le balle con un carrello elevatore e tagliare i fili/le reggette prima che entrino nella macchina. Il processo di sballatura è completamente automatizzato.