Kompleksowy przewodnik po maszynach do recyklingu pianki: typy, zalety i zastosowania

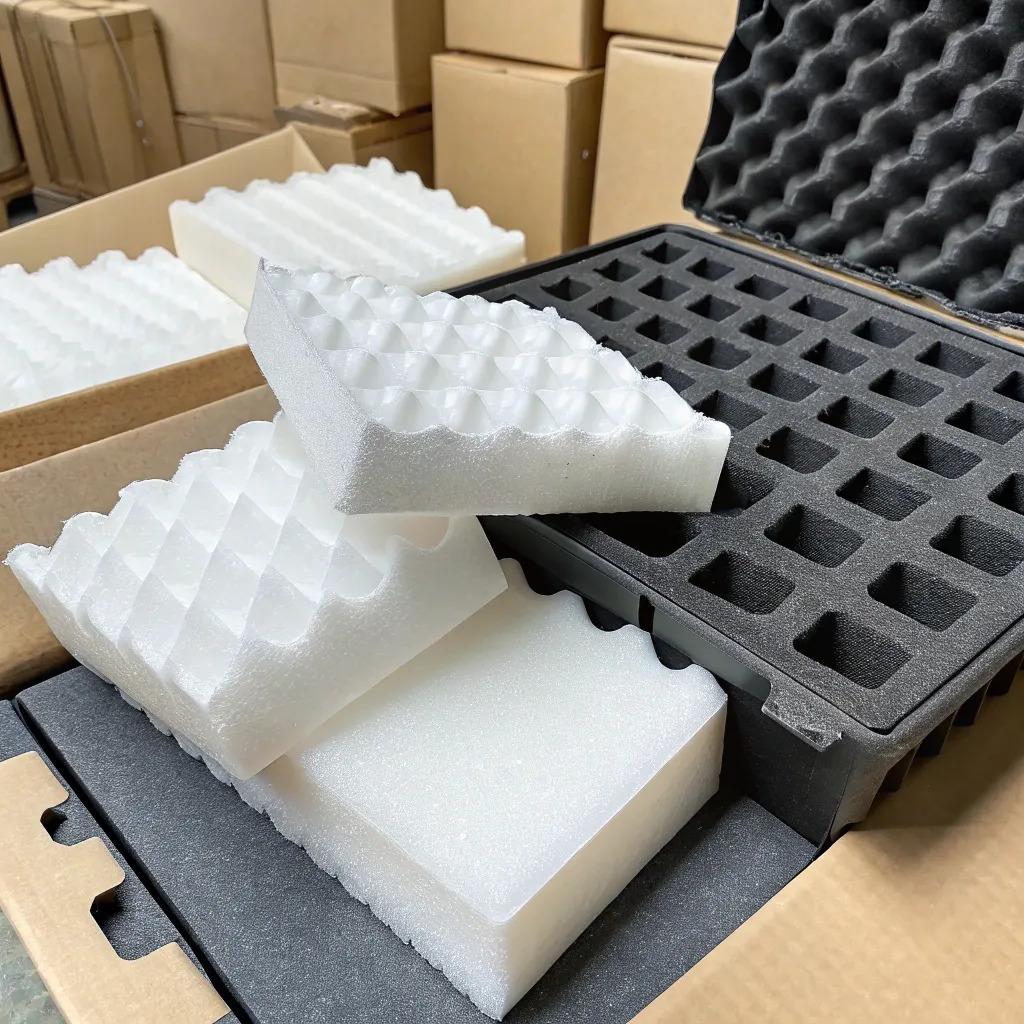

Wyzwanie: Odpady piankowe, zwłaszcza styropian (EPS) i pianka poliuretanowa (PU), stanowią poważne wyzwanie dla środowiska we współczesnym krajobrazie przemysłowym. Materiały piankowe, szeroko stosowane w opakowaniach, izolacjach i produkcji, nie ulegają biodegradacji i zajmują znaczną ilość miejsca na składowiskach odpadów, jeśli są niewłaściwie zarządzane.

Rozwiązanie: Maszyny do recyklingu pianki stanowią innowacyjne i ekonomiczne rozwiązanie w zakresie gospodarowania odpadami pianki, umożliwiając przedsiębiorstwom przetwarzanie, kompresowanie i ponowne wykorzystywanie tych materiałów w celu uzyskania cennych zasobów, jednocześnie znacząco redukując ich wpływ na środowisko.

Zrozumienie maszyn do recyklingu pianki

Maszyna do recyklingu pianki to specjalistyczne urządzenie zaprojektowane do wydajnego przetwarzania i recyklingu różnych rodzajów odpadów piankowych. Maszyny te wykorzystują różne technologie – w tym kompresję mechaniczną, topienie termiczne i rozdrabnianie – aby przekształcić duże odpady piankowe w gęste, łatwe w obsłudze materiały nadające się do ponownego wykorzystania.

Wdrażając Recykling EPS Dzięki tym rozwiązaniom przedsiębiorstwa mogą znacząco zmniejszyć swój wpływ na środowisko, zminimalizować zależność od składowisk odpadów i znacząco obniżyć koszty gospodarki odpadami, przyczyniając się jednocześnie do rozwoju gospodarki o obiegu zamkniętym.

Rodzaje maszyn do recyklingu pianki: Wybór odpowiedniej technologii

1. Zagęszczarki na zimno

Zagęszczarki na zimno stanowią energooszczędne rozwiązanie dla firm przetwarzających duże ilości styropianu (EPS). Maszyny te wykorzystują nacisk mechaniczny bez nagrzewania do kompresji odpadów piankowych w kompaktowe bloki, osiągając współczynnik redukcji objętości na poziomie 50-90%.

2. Maszyny do topienia na gorąco

Maszyny do topienia na gorąco wykorzystują technologię termiczną do efektywnego topienia i zagęszczania odpadów piankowych. Materiał piankowy jest podawany do ogrzewanej komory, gdzie topi się, a następnie jest wytłaczany w postaci gęstych bloków lub wlewków, osiągając imponujący współczynnik zagęszczenia do 90:1.

3. Zagęszczacze termiczne

Zagęszczacze termiczne wykorzystują kontrolowane ciepło do zmiękczania i kompresji odpadów piankowych bez ich całkowitego stopienia. Technologia ta zapewnia wydajne zagęszczanie przy jednoczesnym zachowaniu integralności materiału, co czyni transport i recykling bardziej ekonomicznymi.

4. Rozdrabniacze i granulatory

Rozdrabniacze i granulatory mechanicznie rozdrabniają materiały piankowe na małe kawałki lub granulki, które można bezpośrednio wykorzystać ponownie w procesach produkcyjnych lub poddać dalszej obróbce. Maszyny te doskonale radzą sobie z przetwarzaniem pianki poliuretanowej (PU) powszechnie stosowanej w meblarstwie i pościeli.

Kluczowe korzyści z inwestowania w maszyny do recyklingu pianki

Znaczna redukcja kosztów

Lekka, a jednocześnie duża objętość pianki przekłada się na wysokie koszty transportu i składowania odpadów na wysypiskach. Maszyny do recyklingu zmniejszają objętość pianki nawet o 90%, radykalnie obniżając koszty gospodarki odpadami. Firmy zazwyczaj osiągają zwrot z inwestycji w ciągu 18-36 miesięcy dzięki samym oszczędnościom na kosztach utylizacji.

Łagodzenie wpływu na środowisko

Materiały piankowe mogą przetrwać na wysypiskach przez setki lat bez rozkładu. Poprzez recykling odpadów piankowych firmy aktywnie uczestniczą w inicjatywach gospodarki o obiegu zamkniętym, redukując emisję gazów cieplarnianych związaną z produkcją pianki i zarządzaniem wysypiskami, jednocześnie chroniąc zasoby naturalne.

Możliwości generowania przychodów

Bloki, sztabki i granulki pianki pochodzącej z recyklingu mają wartość komercyjną na rynkach wtórnych. Producenci aktywnie kupują pianki pochodzące z recyklingu do zastosowań w budownictwie, opakowaniach i produkcji, generując dodatkowe źródło dochodu, które rekompensuje koszty inwestycji w sprzęt.

Ulepszony profil zrównoważonego rozwoju przedsiębiorstwa

Współcześni konsumenci i klienci B2B coraz bardziej priorytetowo traktują współpracę z firmami odpowiedzialnymi ekologicznie. Wdrożenie recyklingu pianki świadczy o realnym zaangażowaniu w zrównoważony rozwój, wzmacnia reputację marki, spełnia kryteria ESG (środowiskowe, społeczne i korporacyjne) i potencjalnie otwiera nowe możliwości rynkowe.

Zastosowania przemysłowe: gdzie recykling pianki zapewnia maksymalną wartość

Przemysł opakowaniowy

Procesy pakowania generują znaczne ilości odpadów z pianki EPS z materiałów ochronnych. Maszyny do recyklingu przetwarzają te odpady na kompaktowe bloki, zmniejszając zapotrzebowanie na miejsce do magazynowania i koszty utylizacji, a jednocześnie wspierając inicjatywy dotyczące zrównoważonego pakowania i osiągając cele zrównoważonego rozwoju w firmach.

Produkcja mebli

Pianka poliuretanowa stanowi główny składnik tapicerki meblowej. Producenci wykorzystujący rozdrabniacze i granulatory mogą poddawać recyklingowi odpady produkcyjne i produkty wycofane z eksploatacji, tworząc systemy produkcyjne w obiegu zamkniętym, które obniżają koszty surowców i wpływ na środowisko.

Budownictwo i Izolacja

W projektach budowlanych często wykorzystuje się piankę EPS i XPS do izolacji i zastosowań konstrukcyjnych. Maszyny do topienia na gorąco i zagęszczacze umożliwiają wykonawcom recykling resztek materiałów i odpadów rozbiórkowych, co obniża koszty projektu i spełnia wymogi certyfikacji ekologicznego budownictwa.

Produkcja elektroniki i sprzętu AGD

Producenci elektroniki powszechnie stosują piankę do opakowań ochronnych podczas transportu produktów. Możliwość recyklingu pianki na miejscu upraszcza gospodarkę odpadami, obniża koszty utylizacji i potwierdza zgodność z przepisami dotyczącymi rozszerzonej odpowiedzialności producenta.

Wybór optymalnej maszyny do recyklingu pianki: Ramy decyzyjne

Wybór odpowiedniego sprzętu do recyklingu pianki wymaga starannej oceny wielu czynników operacyjnych i finansowych:

- Identyfikacja rodzaju pianki: Różne maszyny sprawdzają się w przypadku określonych rodzajów pianki. Pianka EPS i XPS najlepiej sprawdzają się w zagęszczarkach na zimno, urządzeniach do topienia na gorąco i zagęszczaczach, natomiast pianka PU wymaga urządzeń do rozdrabniania lub granulowania. Przed wyborem sprzętu należy dokładnie określić skład strumienia odpadów.

- Ocena objętości przetwarzania: Dopasuj wydajność maszyn do tempa wytwarzania odpadów. Małe zakłady mogą odnieść sukces dzięki zagęszczarkom na zimno, natomiast zakłady o dużej przepustowości wymagają solidnych maszyn do topienia na gorąco lub zagęszczaczy termicznych, zdolnych do ciągłego przetwarzania o dużej wydajności.

- Analiza budżetu i zwrotu z inwestycji: Chociaż maszyny do recyklingu pianki wymagają początkowej inwestycji kapitałowej, należy obliczyć całkowity koszt posiadania, uwzględniając oszczędności na kosztach utylizacji, potencjalne przychody z materiałów pochodzących z recyklingu oraz koszty operacyjne. Większość firm osiąga dodatni zwrot z inwestycji (ROI) w ciągu 2-3 lat.

- Wymagania dotyczące przestrzeni i infrastruktury: Oceń dostępną przestrzeń, moc elektryczną, wymagania dotyczące wentylacji i możliwości obsługi materiałów. Upewnij się, że Twój obiekt jest w stanie pomieścić wybrany sprzęt i powiązane z nim procesy operacyjne.

- Zagadnienia dotyczące zgodności z przepisami: Zapoznaj się z lokalnymi przepisami dotyczącymi ochrony środowiska, wymogami dotyczącymi recyklingu oraz potencjalnymi zachętami lub dotacjami na inwestycje w sprzęt do recyklingu. Niektóre jurysdykcje oferują ulgi podatkowe lub dotacje na inicjatywy z zakresu zrównoważonego gospodarowania odpadami.

Wgląd w branżę

Globalny rynek recyklingu pianki dynamicznie rośnie, napędzany przez surowe przepisy ochrony środowiska, zobowiązania przedsiębiorstw do zrównoważonego rozwoju oraz postęp technologiczny. Firmy, które inwestują dziś w infrastrukturę do recyklingu pianki, mają przewagę w kontekście przyszłych wymogów regulacyjnych, jednocześnie zyskując natychmiastowe oszczędności i możliwości generowania przychodów.

Przyszłość recyklingu pianki: nowe trendy i technologie

Branża recyklingu pianki nieustannie się rozwija, wprowadzając innowacje, które zwiększają wydajność, zmniejszają zużycie energii i zwiększają kompatybilność materiałów:

Zaawansowana automatyzacja: Maszyny nowej generacji zawierają czujniki oparte na sztucznej inteligencji i zautomatyzowane systemy sortowania, które optymalizują parametry przetwarzania w czasie rzeczywistym, maksymalizując jakość wyjściową i minimalizując zużycie energii.

Integracja recyklingu chemicznego: %%

Nowe technologie łączą recykling mechaniczny z procesami depolimeryzacji chemicznej, umożliwiając odzysk surowców jakości pierwotnej z odpadów piankowych – przełom dla zamkniętych systemów produkcji. %%

Hybrydowe systemy przetwarzania: %%

Producenci opracowują wielofunkcyjne maszyny łączące różne technologie przetwarzania (kompresję, topienie i granulację) w pojedynczych jednostkach, zapewniając elastyczność operacyjną dla firm zajmujących się zróżnicowanymi strumieniami odpadów piankowych.

%%

Możliwości odzysku energii: Recykling EPS %%

Zaawansowane systemy teraz przechwycają i ponownie wykorzystują ciepło generowane podczas przetwarzania termicznego, znacznie redukując zużycie energii netto i poprawiając ogólną efektywność operacyjną. %%