PVC Plastic Grinder (Pulverizer) for Recycling

Purpose-built for PVC grinding, this machine turns PVC film, sheets, pipes, and profiles into consistent reusable powder. With configurable cooling and dust control, it helps you keep stable output quality while protecting blades and reducing operating costs.

Grinding Process Overview

A typical PVC grinding line focuses on stable temperature, controlled particle size, and efficient powder collection.

Feed & Pre-Cut

Sorted PVC scrap (film/sheets/profiles) is fed consistently for smooth grinding chamber loading.

Pulverizing

Rotor milling turns PVC into powder while process settings help keep output consistent and stable.

Screening & Collection

Powder passes through the screen to meet target mesh and is conveyed to a collection system.

Powder Handling

Collected powder can be stored, bagged, or fed to downstream processes; optional dust collection supports a cleaner operation.

Why Choose This Machine

Configured for stable PVC grinding performance—fine powder, controlled temperature, and cleaner operation for recycling and in-house scrap recovery.

Adjustable Powder Fineness

Screen and process settings allow you to target the mesh range your downstream extrusion or compounding requires.

Temperature Control for PVC

Air/water cooling options help keep grinding stable, reduce heat impact on PVC, and support long-term, consistent production.

Cleaner, Lower-Dust Operation

Optional dust collection improves the working environment and reduces fines loss—especially helpful for PVC film grinding.

High Efficiency

High grinding capacity with low energy consumption supports stable output with strong cost performance.

Built for Durability

Robust structure and wear-part options help extend service life and reduce maintenance downtime.

Versatile PVC Handling

Adaptable to multiple PVC forms and target meshes, supporting different recycling and manufacturing workflows.

Key Features & Capabilities

Designed for PVC grinding: stable grinding, consistent powder quality, and low total operating cost.

Material Processing

Optimized for PVC film, sheets, pipes, profiles, and panels. Many configurations can also process select plastics like HDPE, PP, and PET.

Grinding Mechanism

A rotor blade system with static and rotating blades delivers efficient milling. Adjustable blade settings help target the desired particle size.

Output

Produces coarse granules through fine powder. Typical capacity ranges from 25 kg/h to 900+ kg/h depending on model and material.

Wear Parts

Blade and wear-part configurations can be selected to match PVC types, throughput goals, and maintenance cycles.

Automation

Manual, semi-automatic, and fully automatic configurations are available to match different plant layouts and throughput needs.

Safe Operation

Designed for reliable day-to-day production with stable guarding and an operational setup that supports safer maintenance routines.

Typical Applications

From PVC film grinding to rigid PVC recycling, this grinder supports stable powder production for multiple downstream uses.

PVC Recycling

Convert post-industrial and selected post-consumer PVC into reusable powder for compounding, extrusion, and remanufacturing.

PVC Film & Sheet Grinding

Ideal for reclaiming PVC film and sheet trims with controlled fineness, helping you reduce raw material cost and waste.

In‑House Scrap Recovery

Common in pipe, window/door profile, and flooring plants to reprocess production scrap and stabilize internal material loops.

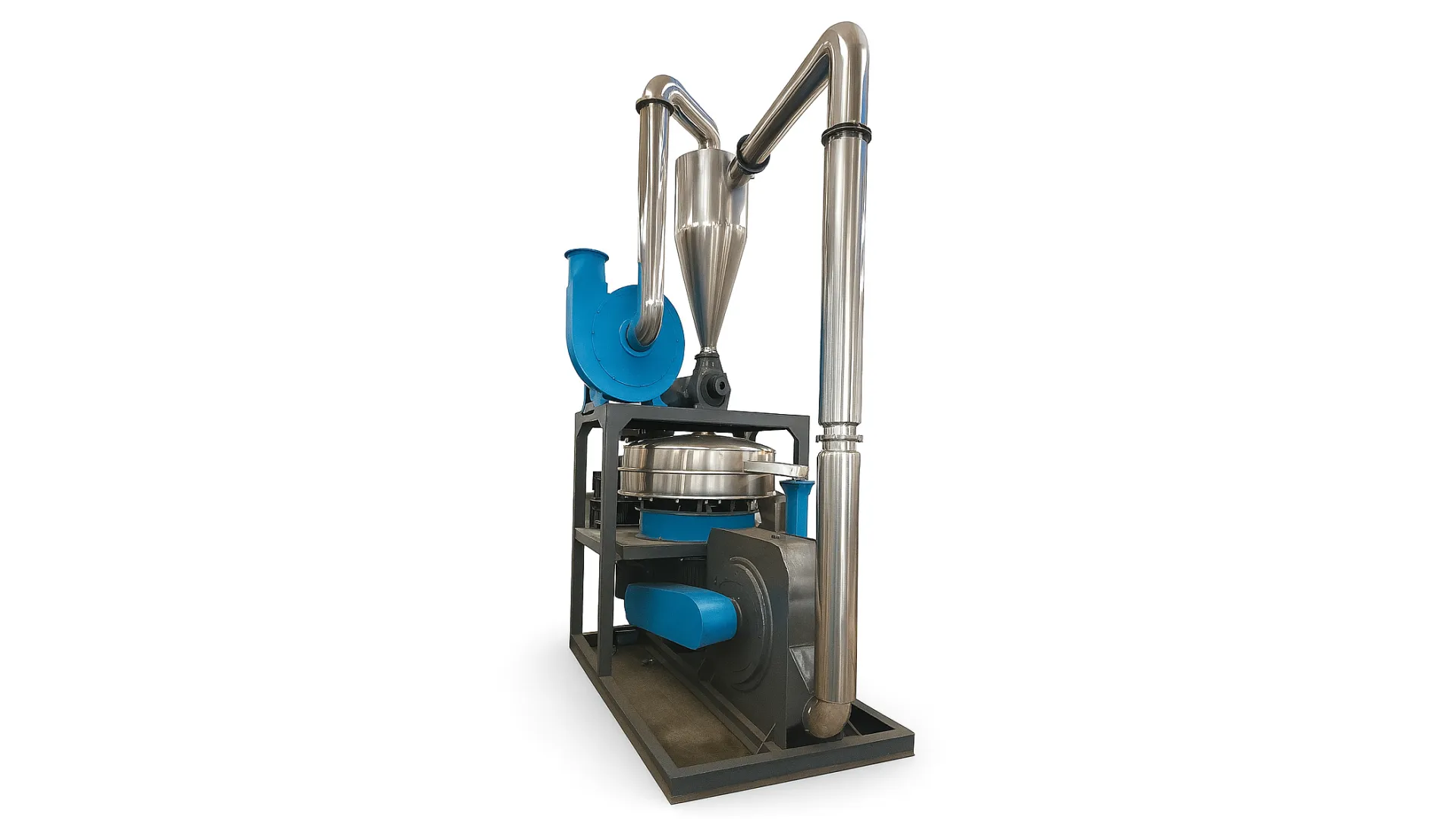

Machine Details & Gallery

A closer look at the PVC grinder structure and build quality.

Technical Specifications

Key configuration items for PVC grinding. Final selection depends on material, target mesh, and throughput.

| Parameter | Options / Notes |

|---|---|

| Materials | PVC film, sheets, pipes, profiles; other plastics subject to configuration. |

| Target Mesh | Adjustable via screen and process settings. |

| Throughput | Varies by model and material; share your required kg/h for recommendation. |

| Cooling | Air cooling / water cooling options for temperature control. |

| Dust Collection | Optional dust control system for cleaner operation. |

| Automation | Manual / semi-automatic / fully automatic configurations available. |

In summary, the PVC plastic grinder is a core piece of equipment in the plastic recycling and manufacturing industries. It efficiently converts PVC waste into reusable materials, supporting more sustainable production.

Warranty & Support

From commissioning to after-sales service, we help ensure stable production and long-term reliability.

1-Year Limited Warranty

All of our PVC plastic grinding machines include a comprehensive one-year limited warranty.

Commissioning Support

We provide installation guidance, parameter setup suggestions, and after-sales support for stable production.

Frequently Asked Questions

What types of PVC scrap can this machine handle?

Our industrial grinders are designed to process a wide range of rigid PVC scrap, including post-industrial pipes, window and door profiles, siding, fence panels, sheets, and other hard plastic waste.

What is the output particle size and capacity?

The final particle size (mesh) is adjustable. Output capacity depends on model and raw material, typically ranging from 100 kg/h to over 500 kg/h for standard configurations.

How does this model differ from a high-performance grinder?

This industrial model is a versatile workhorse for general recycling with excellent durability and cost-effectiveness. High-performance models are engineered for extremely fine, uniform powders and maximum throughput with advanced cooling and milling designs.

What is required for maintenance?

Routine checks include blade sharpness and replacement, bearing lubrication, and screen cleaning. We provide recommended maintenance schedules and support for spare parts.

Request a Quote

Share your material type, target mesh, and throughput—our team will recommend the right configuration for your line.