Plastic Crushers & Granulators for Efficient Recycling

Our range of high-performance plastic granulators and crushers are engineered to transform waste into valuable resources, from PET bottles and industrial scrap to rigid plastics and PVC.

Core Advantages of Our Granulator Series

Versatile Model Range

From compact units to large-scale machines for wet/dry materials, PET, PVC, and bulky rigid plastics.

High-Performance Cutting

Specialized rotors (V-cut, claw-blade) and durable D2 steel knives ensure efficient size reduction and uniform output.

Engineered for Usability

Features like easy-access chambers, adjustable blades, and modular sieves simplify operation and maintenance.

Robust Construction

Heavy-duty design and quality components guarantee long life and reliable performance with tough materials.

Explore Our Granulator & Crusher Lineup

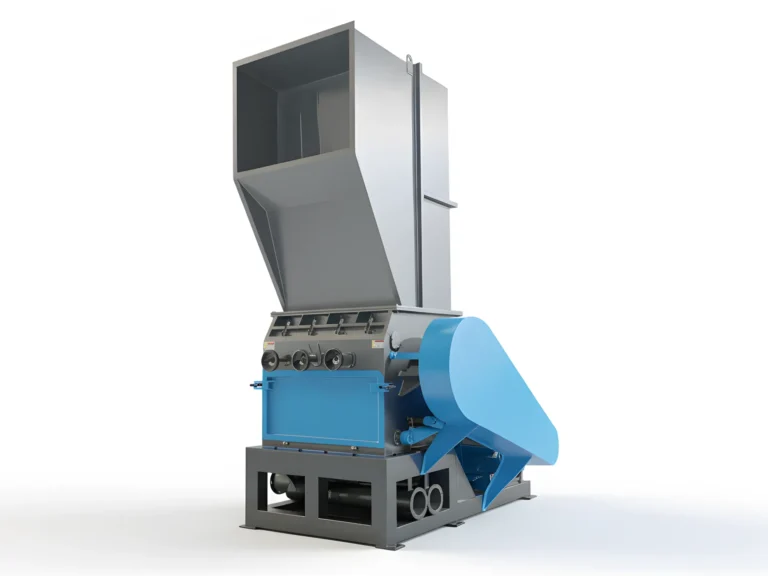

PET Bottle Granulator

A specialized V-cut rotor and force-feeding system produce uniform, high-purity PET flakes with minimal dust.

Small Crusher Machine

An efficient and versatile solution with adjustable blades and a modular sieve for modern recycling operations.

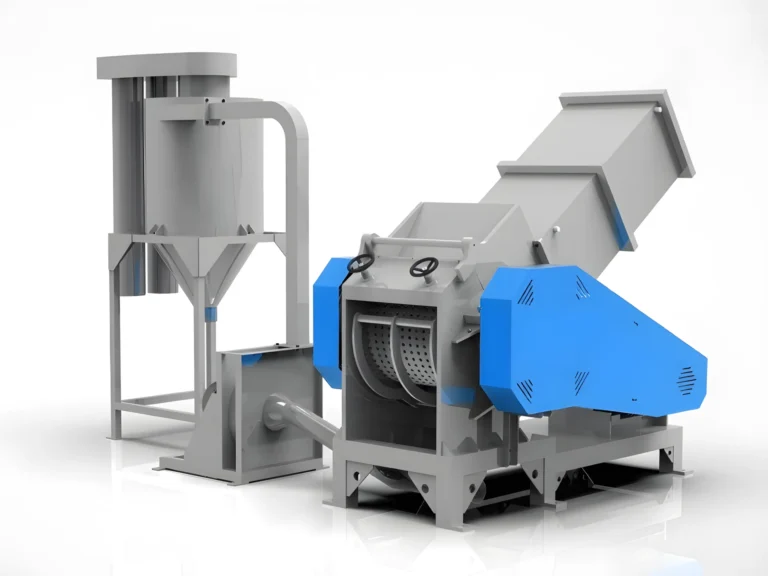

Integrated Shredder-Granulator

Combines high-performance shredding and precise granulation in one compact machine for diverse materials.

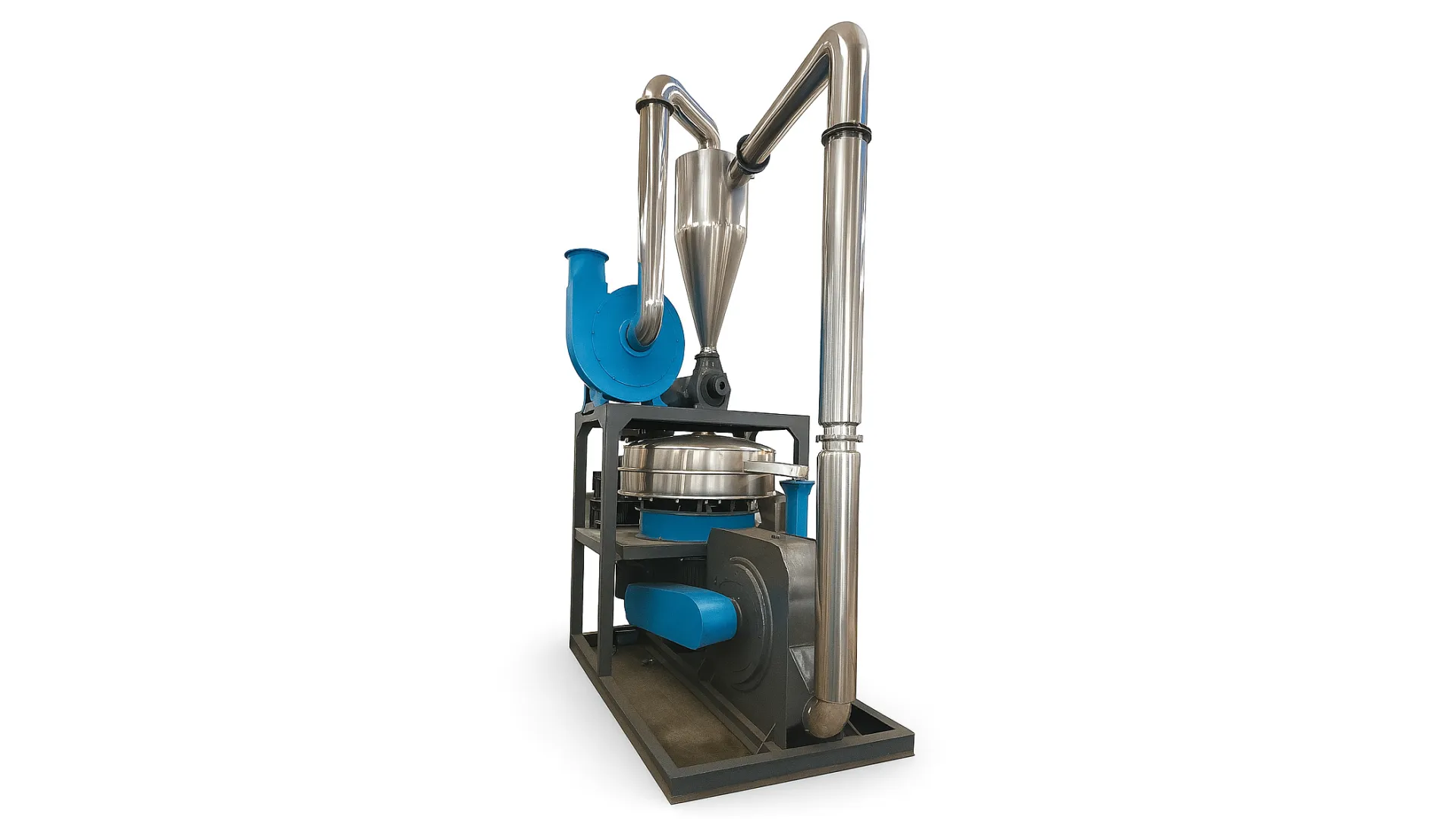

Automatic PVC Pulverizer

This automatic grinding machine efficiently produces fine, uniform powder from PVC granules for specialized applications.

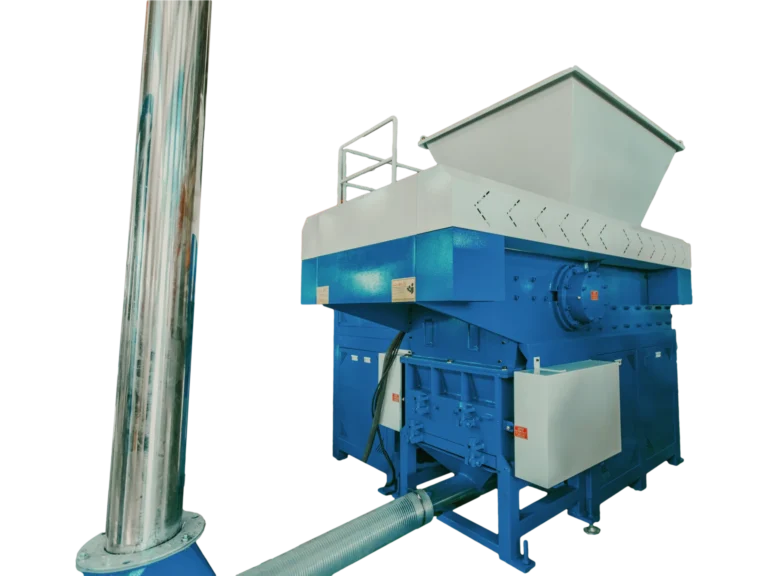

PVC Pipe Horizontal Crusher

A heavy-duty design allows for easy feeding of long pipes without pre-cutting, maximizing safety and efficiency.

Wet Plastic Granulator

Effectively cleans while granulating, ideal for processing wet or contaminated plastic waste to produce cleaner particles.

Lead Ingot Cold Cutting Machine

A safer, fume-free way to produce lead granules by transforming solid ingots without melting, saving energy.

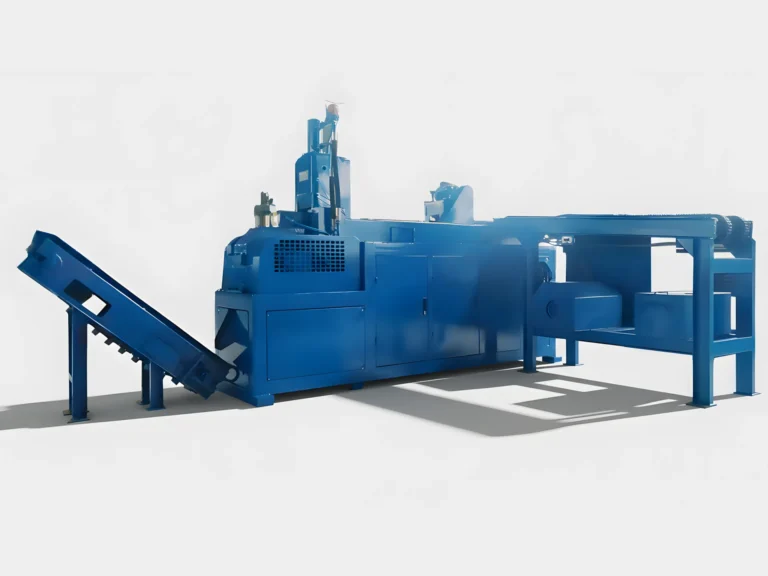

Extra Large Rigid Plastic Granulator

Tackles your bulkiest waste, transforming large items like drums, crates, and pallets into uniform, high-value regrind.

Industrial PVC Pulverizer

Effectively processes diverse PVC scrap and rigid waste like pipes and profiles into reusable, high-quality powder.

Example Technical Parameters (Standard Series)

| Model | Motor (kw) | Moving Blades | Fixed Blades | Rotor (mm) | Feed Opening (mm) |

|---|---|---|---|---|---|

| PC400 | 15 | 12 | 2 | Φ380×400 | 400×320 |

| PC500 | 22 | 18 | 2 | Φ380×500 | 500×320 |

| PC600 | 30 | 24 | 4 | Φ450×600 | 600×450 |

| PC800 | 45 | 30 | 4 | Φ580×800 | 800×550 |

Common Applications

PET Bottle Recycling

Producing clean, high-purity flakes ready for washing and pelletizing.

Industrial Scrap

Processing purgings, runners, and defective parts for in-house reuse.

Bulky Waste Reduction

Handling large items like car bumpers, pallets, drums, and pipes efficiently.

Film & Woven Bags

Effectively granulating soft plastics into uniform pieces for further processing.

Frequently Asked Questions

What is the main difference between a shredder and a granulator?

A shredder is used for primary size reduction of large, bulky items, producing rough strips. A granulator (or crusher) is used for secondary reduction, creating small, uniform granules or flakes, which is often the final step before pelletizing.

How do I choose the right granulator for my material?

The choice depends on your material's type, size, and hardness. For soft films, a standard granulator works well. For thick, rigid plastics like purgings or drums, a heavy-duty granulator with claw-blades is recommended. Contact our experts for a personalized recommendation.

Can these machines handle contaminated or wet plastic?

Yes, our Wet Plastic Granulator is specifically designed for this purpose. It uses water during the crushing process to clean the material and reduce friction, resulting in cleaner output and longer blade life.

Get a Custom Solution & Quote

To get the latest prices, lead times, and a solution tailored to your needs, send us a message using the form below.