Tires are composite products: rubber compounds reinforced with steel wire and textile fiber. That structure is exactly why tire recycling requires a staged process. If you try to run whole tires through equipment designed for plastics, you create avoidable damage and unstable output.

This guide explains the common stages used to turn waste tires into rubber chips, crumb rubber, or powder—and what to check when you choose a tire granulator system.

Quick Takeaways

- Tire recycling is usually a multi-stage system: cutting/debeading → shredding → granulation → separation → (optional) powder.

- Steel and fiber separation quality often decides whether your crumb rubber is sellable.

- Define your end product first; “granulator” can mean different machine classes.

The Tire Granulator “System” (Not One Machine)

In procurement, the most common mistake is treating the granulator like a standalone purchase. Crumb quality is usually decided by the module stack around it: stable feeding, multi-stage steel removal, fiber separation, screening, and dust handling.

| Module | Main job | What it affects | What to ask suppliers |

|---|---|---|---|

| Debeading / cutting (optional) | Improve feeding and reduce wire shock loads | Throughput, knife life, and unplanned stops | When it’s required for your tire mix, and what failures it prevents |

| Primary shredding | Turn whole tires into consistent chips | Downstream stability and separation efficiency | Chip size, throughput on your tire mix, and wear-part plan |

| Granulation | Reduce size while liberating steel | Crumb size distribution, steel carryover, energy/ton | Screen options, knife change time, and steel removal integration |

| Magnetic separation | Remove liberated steel wire | Final steel contamination and equipment protection | Number of magnet stages, cleaning method, and target steel limits |

| Fiber separation | Remove textile fiber from crumb | Crumb cleanliness and buyer acceptance | Air system sizing, dust control, and adjustable separation settings |

| Powder module (optional) | Produce finer rubber powder | End-market access and dust control needs | Cooling, classification, and housekeeping requirements |

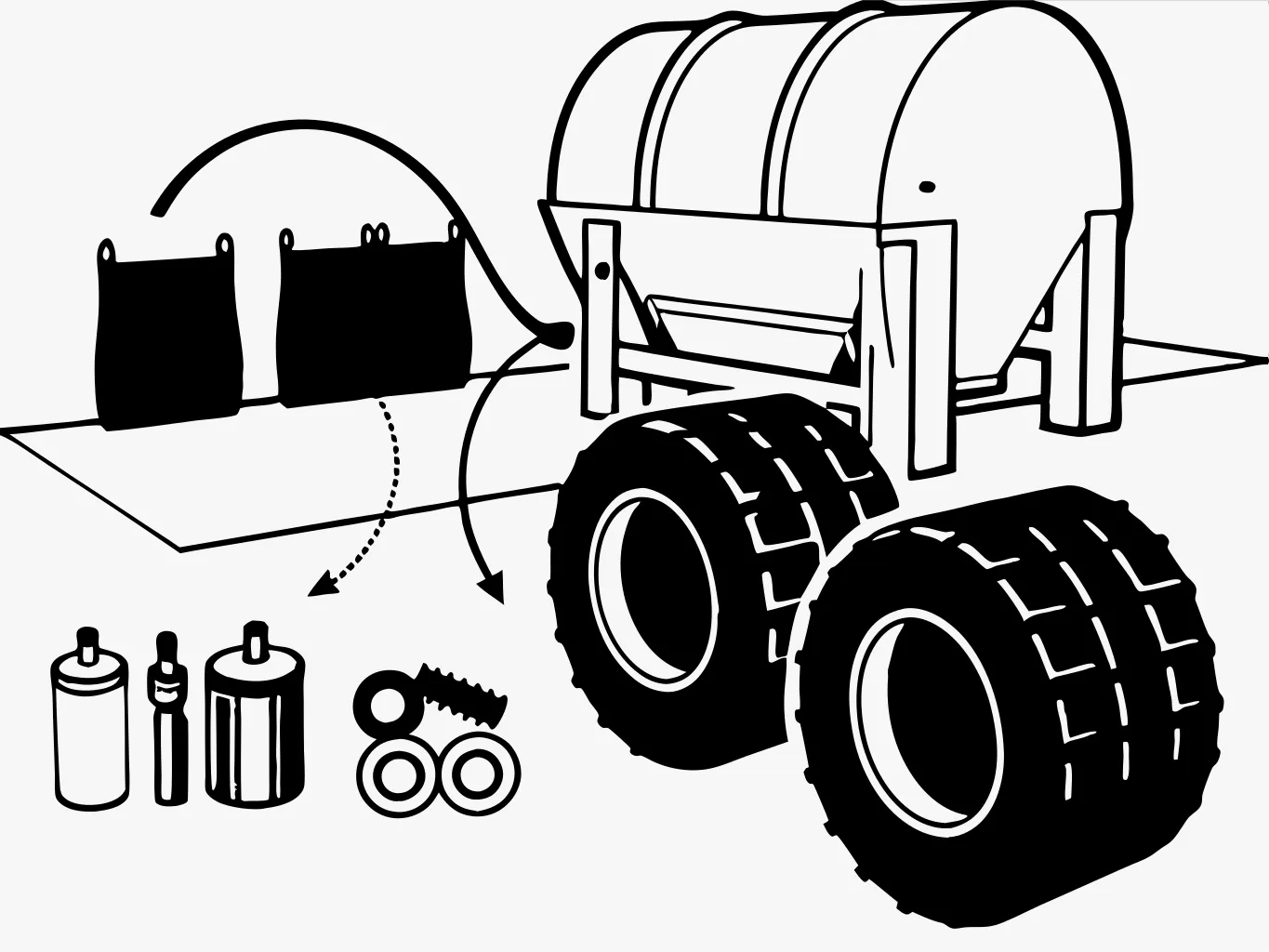

Stage 0: Pre-Processing (When Needed)

Many lines add dedicated pre-processing to improve throughput and protect downstream knives: – debeading (removing bead wire) – sidewall cutting or tire cutting for stable feeding

Energycle equipment references: – single hook tire wire debeading machine – waste tire cutting machine

Stage 1: Primary Shredding (Size Reduction Into Manageable Chips)

Primary shredding turns whole tires into chips suitable for separation and further granulation.

What to verify: – tolerance to mixed tire types (passenger vs truck) – knife and shaft durability under steel reinforcement – discharge size control and safe conveying

Energycle tire shredder reference: tire shredder

Stage 2: Granulation (Steel Liberation and Chip Refinement)

This is where “tire granulator” typically applies: machines designed to cut rubber and progressively free steel wire from the rubber matrix.

Key success factors: – stable feeding (chips, not whole tires) – knife access and maintenance time (rubber is abrasive) – integration with magnetic separation to remove liberated steel continuously

Stage 3: Fiber Separation and Crumb Rubber Quality

As rubber size decreases, textile fiber becomes a major contaminant. Lines typically add: – air separation / aspiration – screening/classification steps to control product size

Your end market will decide what “clean enough” means, so define acceptance criteria with buyers early.

Dust, Noise, and Housekeeping (A Real Uptime and Safety Factor)

Granulating and grinding create dust and fines, and tire facilities often run high hours. Poor housekeeping shows up as more than a safety issue—it becomes an uptime issue (blocked ducts, dirty sensors, and more frequent clean-outs).

When you design a plant, plan: – dust collection capacity sized to each process stage – clean-out access points and a realistic maintenance routine – guarding and energy-control procedures for routine cleaning

OSHA’s information on combustible dust and machine guarding can help frame baseline expectations for dust management and safe maintenance planning.

Stage 4 (Optional): Rubber Powder Production

Powder production is a different operating regime and often requires specialized grinding systems and tighter dust control. Projects choose powder when the end market pays for it and when they can manage the higher maintenance and process control demands.

Energycle tire recycling line reference: tire rubber recycling pulverizing grinder

A Buyer Checklist for Tire Granulator Projects

- What is the target product (chips, crumb, powder) and who buys it?

- What is the permitted contamination level for steel and fiber?

- What tire mix will you process (car, truck, OTR) and what volume?

- What site constraints exist (noise, dust, permitting, power, space)?

- What service plan will you use for knife and screen wear parts?

If you share your target product and feedstock, Energycle can help you configure the staged system via its contact page.

Specs to Define Before You Request Quotes

| Spec item | Why it matters | What to define |

|---|---|---|

| Tire mix | Wire load and wear differ by tire type | Passenger vs truck vs OTR; bead removal approach; expected contamination |

| Target product | Defines screens and separation scope | Chip vs crumb vs powder; target size range; oversize allowance |

| Steel and fiber limits | Drives magnet and air separation design | Allowed steel and fiber carryover; how acceptance will be measured |

| Throughput and duty cycle | Determines sizing and spares | kg/h target and shifts/day; peak vs average loads |

| Site constraints | Often blocks projects after purchase | Noise/dust limits, power availability, footprint, lifting access |

FAQ (Real Procurement Questions)

Do I need a debeader for passenger tires, or only for truck tires?

It depends on your tire mix, your desired throughput, and how much shock load your downstream equipment can tolerate. A debeader can reduce the severity of bead wire events that damage knives and screens and can improve feeding stability, but it adds capex and an extra operating step. Ask suppliers to justify it with a similar reference case: tire types, pre-processing steps, and the downstream granulator configuration. If your buyer spec requires very low steel carryover, the case for upstream wire management becomes stronger. The right answer includes downtime and wear-part comparisons with and without debeading.

How many magnetic separation stages do I really need?

Usually more than one if you want clean crumb rubber. Steel isn’t fully liberated at the first cut; it becomes freer as size is reduced. Multi-stage magnets remove steel at different points and protect downstream equipment. Ask suppliers where magnets are placed (before and after key cutting steps), how magnets are cleaned, and what steel contamination level they can demonstrate in the final product. Also ask what happens when steel load spikes (for example, mixed tire types or contaminated feed). The “right” answer is a measured output spec, not “we include a magnet.”

What’s the most common reason crumb rubber projects miss quality targets?

Misaligned assumptions about contamination and separation. Buyers often focus on granulator horsepower and ignore that fiber removal and stable screening decide product cleanliness. If fiber content is too high or particle size distribution is wide, customers reject loads or demand price reductions. Require a defined acceptance test for steel and fiber and ask for proof on comparable installations. Also require a plan for dust and fines handling; fines can carry fiber and can create housekeeping and safety issues if the air system is undersized. Quality is a system outcome, not one machine feature.

When does it make sense to add a powder stage?

Add powder only when you have a buyer who pays for it and when your plant can manage the extra process control. Powder production typically needs cleaner feed, more screening/classification, and stronger dust control than crumb production. It also raises wear and maintenance requirements. Before you buy a powder module, define the powder spec with the buyer (particle size distribution and contamination limits), then confirm the supplier’s reference case at a similar spec. If you don’t have a committed end market, powder often becomes a cost center rather than a value upgrade.

Where can I find industry context on end-of-life tire markets?

For U.S. context, the EPA’s scrap tire overview is a good starting reference for program and end-use categories. Industry reporting also tracks how end-of-life tire volumes are consumed by end-use markets; USTMA publishes end-of-life tire management reporting that can help you sanity-check market assumptions before you size equipment. These sources won’t pick your machine for you, but they help you avoid building a line for a market that isn’t there. (Sources: U.S. EPA scrap tire overview and USTMA 2023 end-of-life tire report page)