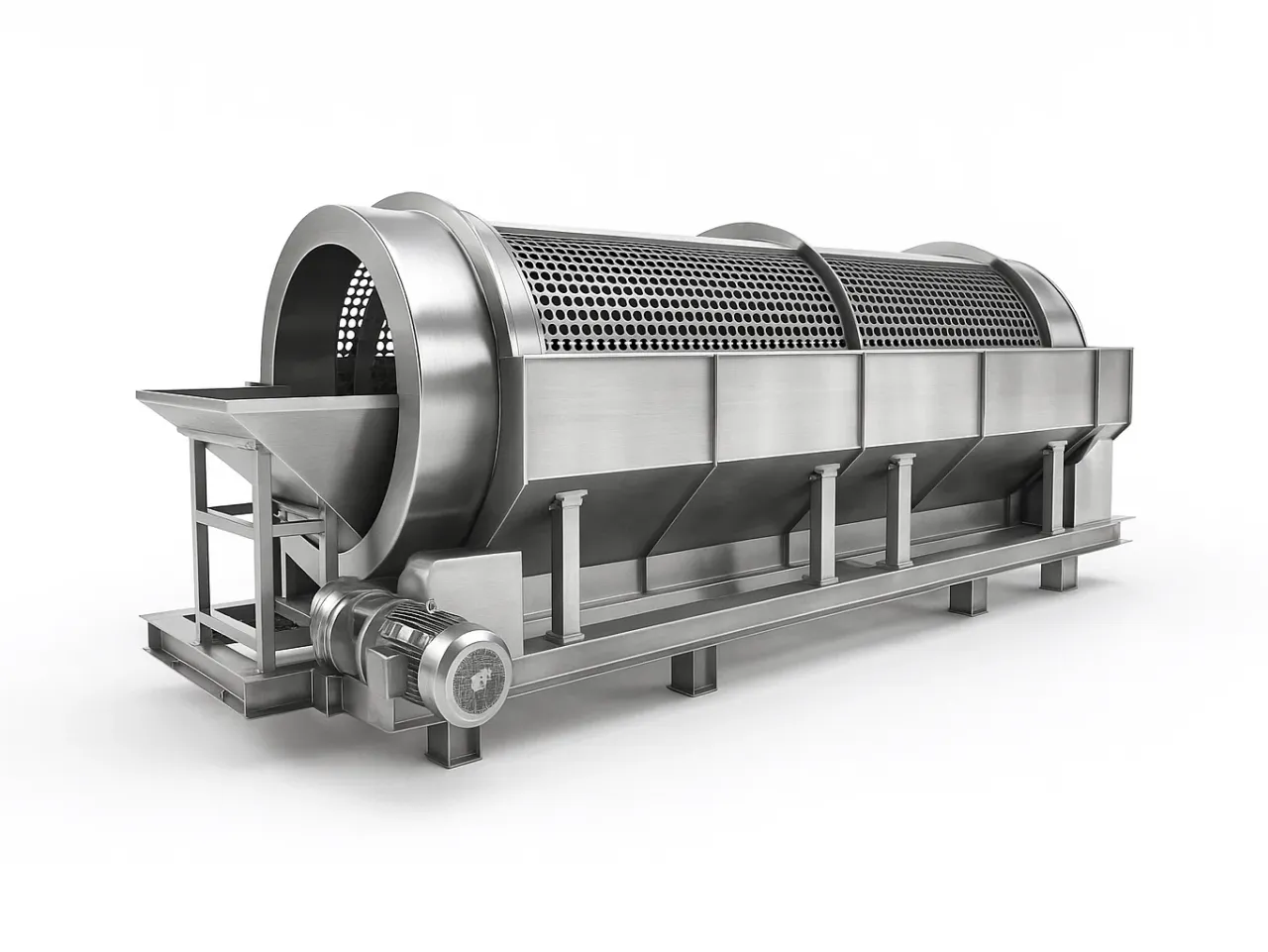

Trommel Machine for Plastic Recycling

Ensuring purity in plastic recycling. Our robust trommel machines effectively filter contaminants and separate materials, providing a clean feed for downstream processing.

The Sorting Process

Simple, reliable, and highly effective trommel screening technology to separate small contaminants from your plastic stream.

Feeding & Tumbling

Raw material enters the large rotating drum. Internal flaps continuously flip and guide the stock forward, ensuring thorough exposure.

Screening

As the drum rotates (6-10 RPM), smaller contaminants like glass, sand, and fines pass through the mesh screen holes.

Separation & Discharge

Target materials larger than the mesh stay inside and are discharged at the end, while contaminants fall into a collection hopper below.

Engineered for Efficiency

Built to handle the heavy demands of modern Material Recovery Facilities (MRFs) and high-capacity plastic recycling plants.

Self-Cleaning System

Equipped with automatic brush units that continuously clean the mesh filters during operation, preventing clogging and reducing maintenance downtime.

Robust Drive Options

Available in 2-wheel or 4-wheel drive configurations to suit different operational loads and environmental conditions.

Variable Control

Includes frequency inverters for precise speed control and synchronization, allowing operators to optimize throughput for specific material types.

Technical Specifications

Standard dimensions and performance metrics. Custom sizes available on request.

| Machine Model | Standard Industrial Trommel |

|---|---|

| Drum Dimensions | ⌀2000mm x 1200mm (Length) |

| Motor Power | 11KW x 2 (Main Drive) |

| Rotating Speed | 6 - 10 RPM (Adjustable) |

| Tilt Angle | 3 Degrees |

| Features | Auto-Cleaning Brushes, Variable Frequency Drive |

| Compliance | CE Certified |

Warranty & Installation

1-Year Limited Warranty

Includes comprehensive coverage for structural components and motors, ensuring peace of mind for your investment.

Commissioning Support

We provide detailed installation guides and operational training to ensure your team gets the most out of the equipment.

Frequently Asked Questions

Can the mesh size be customized?

Yes, the mesh screen size is fully customizable depending on your target material and the size of contaminants you need to filter out.

What materials can this trommel process?

It is highly versatile and effective for mixed municipal waste, plastic bottles (PET/HDPE), mixed films, and even compost or biomass separation.

How often do the brushes need replacing?

The nylon brushes are durable and long-lasting. Typically, they need inspection every 6 months and replacement every 12-18 months depending on usage intensity.

Ready to Optimize Your Sorting?

Get a quote for a standard or custom Trommel Machine today.

Comments are closed.