Manual sorting is difficult work: it’s repetitive, exposes workers to hazards, and becomes less reliable as throughput increases. That’s why recycling plants increasingly use sensor-based sorting and automation. “AI” is now part of that toolset—mostly through vision systems and robotic picking that can help identify items and remove contaminants.

This article explains what AI-supported sorting can realistically do in plastic recycling, where it fits in the process, and what you should verify before investing.

Kurzgefasste Erkenntnisse

- AI-based vision is typically a complement to optical sorting, not a replacement for the whole plant.

- The best use cases are targeted contaminant removal, quality polishing, and labor reduction in repetitive sorting zones.

- Performance depends heavily on feed presentation and maintenance, not only on the camera or software.

“AI Sorting” vs “Optical Sorting”: What Buyers Should Understand

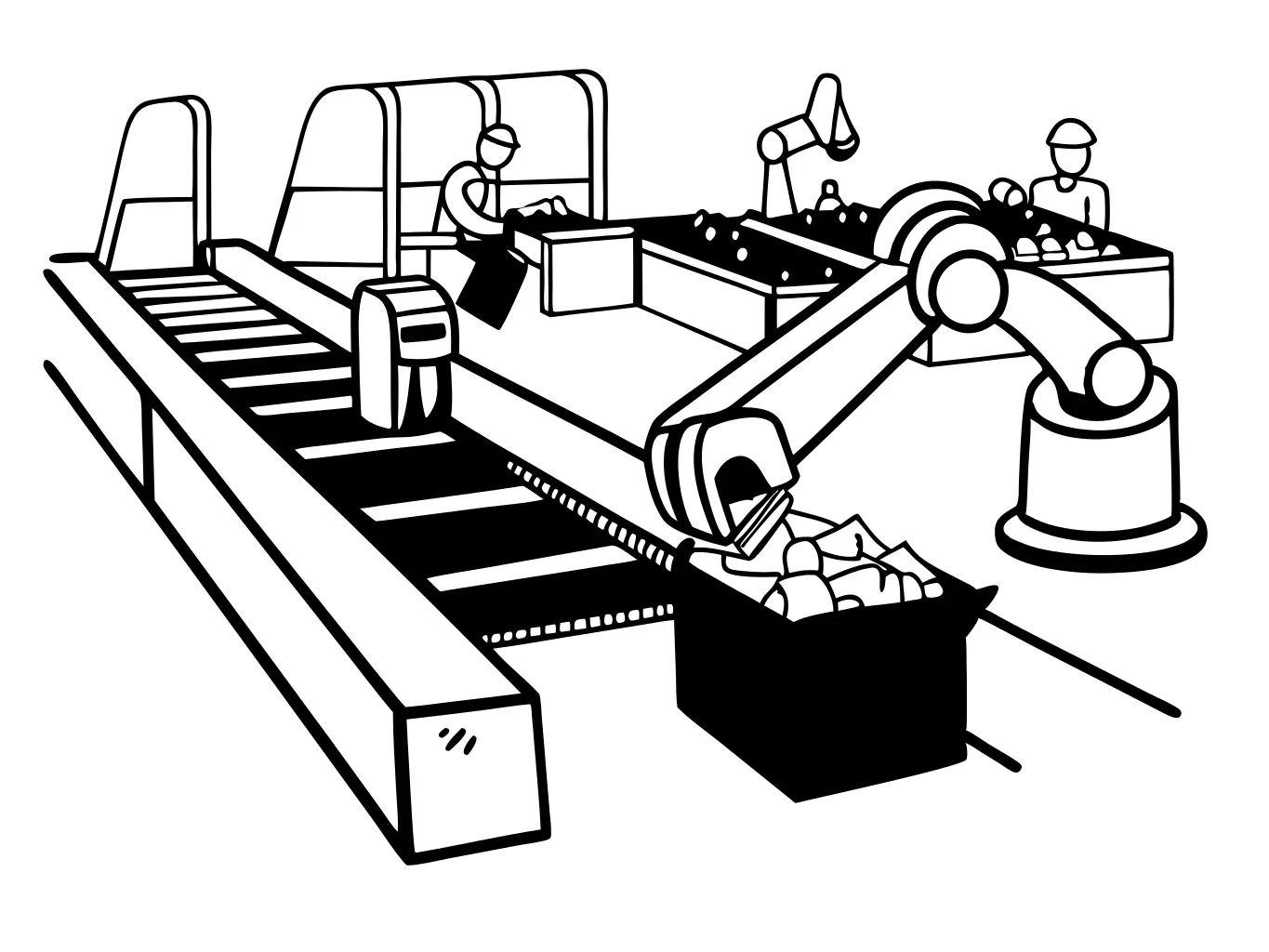

Plants often say “AI sorting,” but most systems are combinations of: – Sensoren that detect material properties (commonly optical/NIR-based approaches) – Software models that classify items (often labeled “AI”) – Actuators that physically separate items (air jets, mechanical diverters, or robot grippers)

AI typically improves classification Und target selection. It does not replace the need for stable feeding, proper belt loading, and planned maintenance.

Where AI Fits in a Modern Sorting Line

Most high-performing lines combine multiple stages:

- mechanical preparation (fines removal, 2D/3D separation)

- Metallentfernung

- optical sorting (polymer and color separation)

- quality polishing (manual QC and/or robotic picking)

Energycle integrates sorting systems within turnkey recycling lines when the output spec requires it; see its MSW-Sortiermaschinen Überblick.

Common AI-Enabled Sorting Use Cases (And What Else You Still Need)

| Use case | What AI can help with | What must be true upstream | Typical failure mode |

|---|---|---|---|

| Quality polishing (“last few %” removal) | Identify and remove specific contaminants with fewer manual pickers | Stable belt loading, consistent lighting, controlled item overlap | Overlapping material hides targets; output quality drifts |

| Targeted item removal | Remove problem items that cause downstream defects (e.g., wrong resin/color) | Clear target definition, good presentation, and a consistent stream | Stream changes and the model needs re-training |

| Labor reduction in repetitive zones | Reduce repetitive manual sorting tasks | Maintenance and cleaning routines keep sensors reliable | Downtime increases because cleaning/calibration is neglected |

What AI-Based Sorting Can Help With

1) Targeted contaminant removal

Robotic picking can remove specific items that cause quality issues downstream (for example, non-target plastics, metals missed earlier, or heavily contaminated pieces).

2) Flexible identification logic

Vision systems can learn new targets over time (new packaging formats, new label types), which can help plants adjust without rebuilding mechanical separation.

3) Labor reduction in specific zones

Automation can reduce the number of manual picking stations required for the same throughput—especially in polishing steps where the goal is “remove the last few percent of contaminants,” not bulk separation.

What AI Sorting Does Not Solve by Itself

- Poor feed presentation: if items overlap heavily or move unpredictably, any sensor system struggles.

- High contamination streams without front-end prep: dirty, wet, and tangled material needs mechanical preparation first.

- Quality specification without QC: you still need sampling, bale audits, and clear acceptance criteria.

APR’s model bale specifications are one example of how the market defines acceptance criteria for many recycled streams; use them as a template for building “what we accept” and “what we reject” into your plant QC language. (Source: APR-Modellballenspezifikationen)

How to Evaluate an AI Sorting Proposal

Ask for: – the exact target items and the expected output spec (define “success”) – integration details (belt speed, lighting, air system, maintenance access) – how the system is trained and updated (and who owns the model updates) – downtime plan (what happens when a camera is offline or calibration drifts)

Add these procurement questions and you’ll avoid most surprises: – What is the target purity and recovery, and how will it be measured during acceptance testing? – What is the cleaning/calibration schedule, and what happens to performance if it’s missed? – What spare parts are required on-site (cameras, lights, belts, valves, grippers)? – What is the software update and model change process, and how is downtime handled?

If you want to evaluate whether automation makes sense for your stream, share material photos and target product details via Energycle’s Kontaktseite.

ROI Reality: How Plants Typically Win (or Lose) With AI Sorting

AI sorting usually makes sense when at least one of these is true: – labor is a bottleneck or a safety concern in a repetitive sorting zone – your buyer penalizes contamination strongly (price deductions and rejected loads) – you need to “polish” a stream after bulk optical sorting to reach a tighter spec

It often fails when feed presentation is uncontrolled or when the plant expects AI to replace upstream mechanical preparation.

Commissioning and Acceptance Testing (Make AI Measurable)

AI sorting performs best when you define success as purity and recovery on a defined input condition. Before you buy, ask the supplier to propose an acceptance plan that includes:

- a representative input stream (photos, contamination window, moisture condition)

- defined KPIs (purity, recovery, throughput at steady operation, and cleaning downtime)

- a sampling method (how samples are collected and how purity/recovery are calculated)

- a maintenance plan (lens cleaning, air-jet checks, model updates, and who does what)

If a proposal only shows “demo video performance” without a measurable plan, it is not a production-ready procurement package.

FAQ (Real Buyer Questions)

Will AI sorting replace optical sorters?

Usually no. AI often improves the system’s ability to recognize and select targets, but optical sorting is still doing much of the heavy lifting in many plants. In practice, facilities combine mechanical preparation, metal removal, optical sorting, and then a “polishing” step where robotics can remove a smaller set of contaminants. If you want to replace an optical stage with robotics, ask vendors to prove throughput and purity at your material presentation (overlap, belt loading, moisture). The system has to separate material consistently at production speeds, not just in a demo.

What information should I give vendors so proposals are comparable?

Provide three things: (1) a defined input stream (photos, contamination list, moisture condition, bulk density), (2) a defined output spec (target polymer, color limits, contamination limits), and (3) a measurement method for acceptance testing. Without these, vendors will quote assumptions and you won’t be able to compare performance claims. APR’s model bale specifications are a useful example of how specs are structured in the market, even if your plant uses a different grade system. Ask each vendor to map their targets and KPIs to your spec language. (Source: APR-Modellballenspezifikationen)

What maintenance tasks matter most for AI sorting performance?

Cleaning and calibration. Cameras, lights, lenses, and air systems drift over time, and contamination on optics can quickly reduce recognition accuracy. Ask for a documented cleaning schedule, an estimated time per shift, and what “normal” performance loss looks like when cleaning slips. Also ask what spare parts you need in inventory and how long it takes to swap a failed camera or light module. The fastest way to lose ROI is to buy a high-performance system and then underfund the daily maintenance routine that keeps it performing consistently.

Where do AI systems fail most often in plastic recycling?

Feed presentation. Overlapping items, uneven belt loading, and tangled material reduce detection and pick accuracy. High contamination streams also need front-end preparation; otherwise the AI system is trying to solve mechanical problems with software. The easiest way to reduce risk is to require a material trial or a detailed simulation that matches your real operating conditions: belt speed, item overlap, moisture, and contamination. If the vendor can’t explain how performance changes as presentation quality changes, expect unstable output quality after startup.

Who owns the data and the model updates?

This is a contract question, not only a technical one. Ask what data is stored, where it’s stored, and who can use it. Also ask how model updates are handled: do you get updates automatically, do updates require downtime, and can the system be re-trained for new packaging formats or new contaminants? Clarify what happens if the vendor changes software terms or the product line. A good proposal treats data ownership, update cadence, and fallback modes as part of the uptime plan, not as small print.

What sources can I use to sanity-check claims about recycling infrastructure?

For U.S. context, EPA publishes recycling infrastructure assessment and data collection reports that can help you understand how collection, MRFs, and processing capacity are discussed at a national level. These reports won’t tell you whether a specific AI system will work, but they do help you separate “technology potential” from “system capacity” discussions. Combine that macro context with your own buyer specs and trial data. (Source: U.S. EPA recycling infrastructure reports)