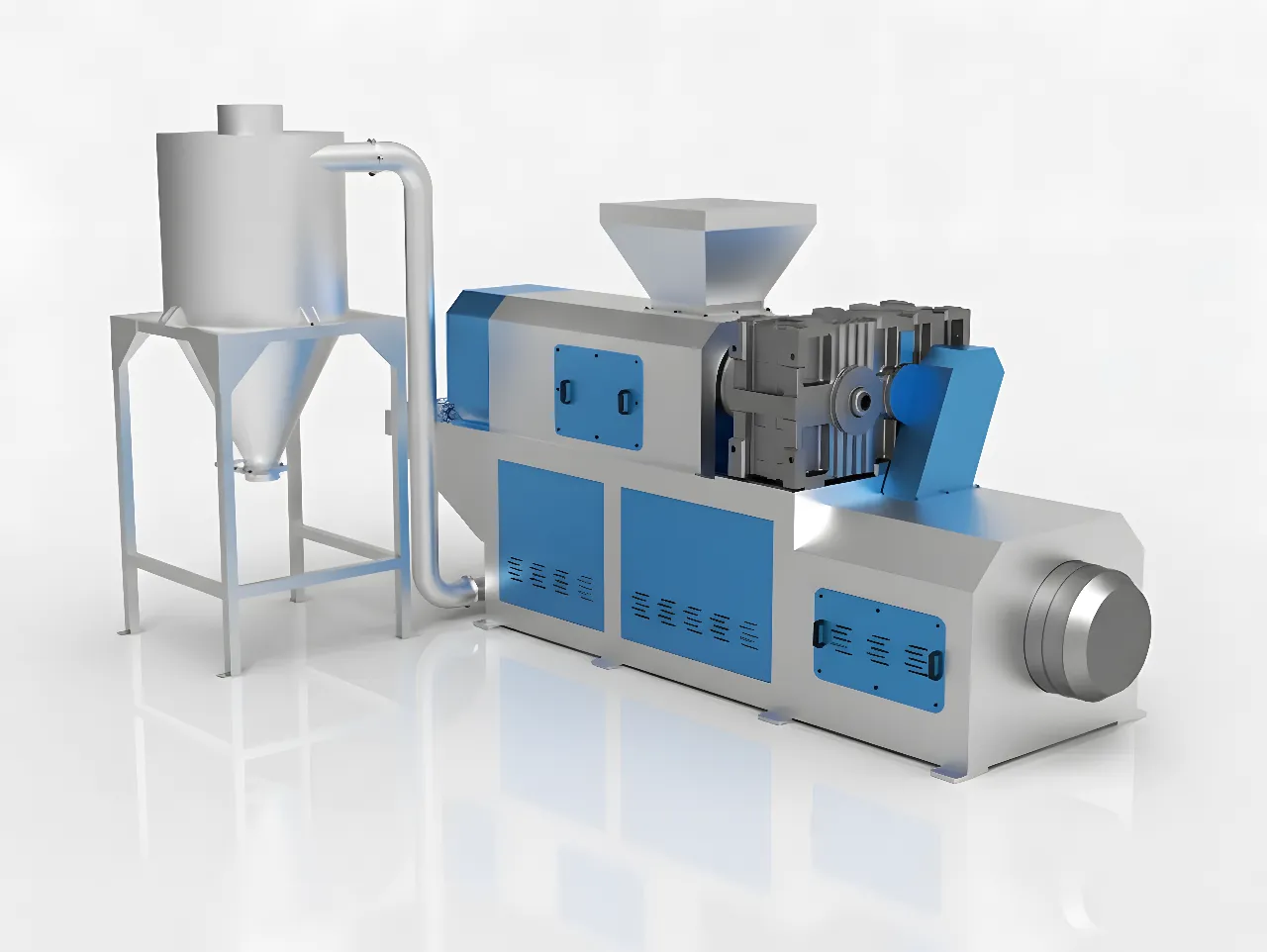

Sistema de deshidratación con prensa de tornillo

A robust, cost-effective alternative to thermal heaters. Our screw press system efficiently extracts moisture from PE films, pulp, and wastewater, delivering outstanding dryness with minimal energy consumption.

Why Choose Our Screw Press?

Engineered to outperform traditional drying methods, our system combines durability, efficiency, and versatility into one powerful unit.

Superior Moisture Removal

Reliably reduces moisture content to below 15%, ensuring your material is perfectly prepared for downstream thermal drying or pelletizing.

Eficiencia energética

Utilizes purely mechanical pressure to squeeze out water, offering massive energy savings compared to energy-intensive thermal heating systems.

Aplicación versátil

Proven reliability across multiple industries, including plastic recycling (PE films), food processing waste, and paper & pulp sludge.

The Ingenious Principle

A progressive compression design ensures gentle yet effective dewatering.

Alimentación

Wet material enters via the vertical feeder where the screw shaft is at its narrowest diameter.

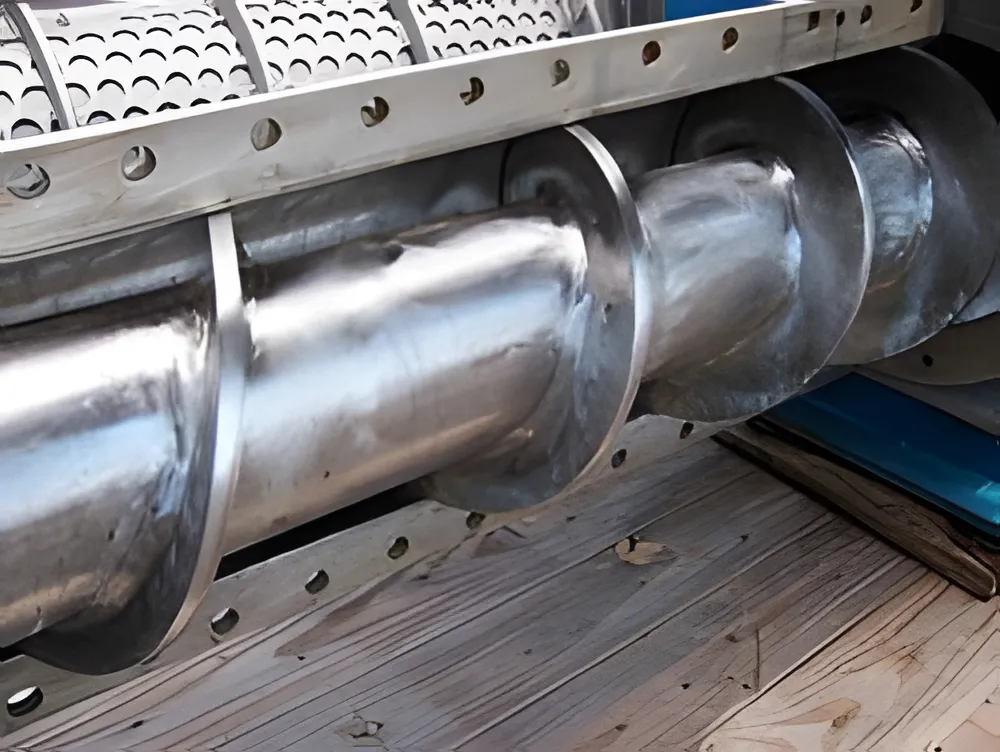

Compresión

As the shaft rotates, its diameter increases, gradually compressing the material against the perforated outer casing.

Descargar

Water is squeezed out through fine perforations, while the dried plastic exits a narrow, precision-engineered gap.

Ingeniería de precisión

The robust outer casing features thousands of meticulously drilled perforations. These allow water to drain freely while retaining solid materials, even under high pressure. The variable-pitch screw shaft is designed to prevent clogging while maximizing throughput.

Especificaciones técnicas

| Tipo de máquina | Industrial Screw Press Dewatering System |

|---|---|

| Contenido de humedad final | < 15% (Material dependent) |

| Machine Length | 4 – 6 Meters (Customizable) |

| Drainage Method | Fine Perforated Casing |

| Operation Mode | Continuous Mechanical Compression |

| Componentes clave | Variable Pitch Screw Shaft, Heavy-Duty Gearbox |

| Aplicaciones | PE Film, Pulp, Sludge, Food Waste |

Aplicaciones ideales

Our screw press serves critical roles in various sectors where moisture reduction is key.

Reciclaje de plástico

Essential for PE film washing lines, effectively removing water from washed flakes before thermal drying.

Tratamiento de aguas residuales

Drastically reduces sludge volume and weight, lowering disposal costs and simplifying handling.

Paper & Pulp

Efficiently dewaters pulp suspensions and fibrous rejects in paper mill operations.

Garantía e instalación

1-Year Limited Warranty

All of our screw press dewatering systems include a comprehensive one-year limited warranty, covering all mechanical components against manufacturing defects.

Soporte de puesta en servicio

We provide full installation guidance, recommended parameter setups, and dedicated after-sales support to ensure your production runs stably from day one.

Preguntas frecuentes

What is the typical output moisture content?

For most soft plastics like PE films, the system can reliably reduce moisture content to below 15%. This is an ideal level for feeding into a subsequent thermal drying system or agglomerator.

How does this compare to a centrifugal dryer?

Screw presses apply much higher pressure and are generally more effective for materials that hold water stubbornly, like thin films or sludge. They run at lower speeds, resulting in less noise and lower maintenance compared to high-speed centrifugal dryers.

Can the machine length be customized?

Yes. While our standard industrial units range from 4 to 6 meters, we can customize the screw length and diameter to match your specific facility layout and throughput capacity requirements.

Is the machine easy to maintain?

Absolutely. The slow rotational speed means less wear and tear on components. The perforated casing is designed for self-cleaning or easy external cleaning, and the robust gearbox requires only standard periodic maintenance.

¿Listo para aumentar su eficiencia?

Contact us today for the latest pricing, lead times, and to discuss how our Screw Press Dewatering System can meet your specific needs.