Face à la demande mondiale croissante de plastiques recyclés, les technologies de traitement efficaces deviennent essentielles. Plastique humide granulateur Les machines sont au cœur des lignes de recyclage modernes car elles permettent de broyer, concasser et laver les déchets plastiques contaminés en une seule étape simplifiée. Ce guide explique le fonctionnement de la granulation humide, met en lumière ses avantages par rapport au traitement à sec et présente les principales caractéristiques de nos systèmes de granulation humide pour plastique.

Pourquoi utiliser un granulateur à plastique humide ?

La granulation à sec classique décompose les déchets plastiques, mais ne permet pas d'éliminer les contaminants de surface tels que les étiquettes, la saleté et les résidus. Les granulateurs à voie humide intègrent l'eau dans la chambre de coupe, ce qui permet à la machine de :

-

Brisez les déchets plastiques en petits flocons tout en rinçant simultanément la saleté et les étiquettes.

-

Réduire au minimum la production de poussière, améliorant ainsi la qualité de l'air en aval

-

Réduire la friction et l'accumulation de chaleur, protégeant ainsi le matériau de la dégradation thermique

-

Fournir des paillettes plus propres et prêtes à être lavées pour une meilleure efficacité de recyclage

Cette combinaison rend la granulation humide idéale pour le traitement des plastiques post-consommation tels que les bouteilles, les films et les contenants rigides.

Comment fonctionnent les granulateurs de plastique humide ?

Les granulateurs humides associent un rotor puissant et des lames fixes à une pulvérisation d'eau continue. En fonctionnement :

-

Alimentation et réduction de taille avant alimentationLes plastiques contaminés pénètrent dans la trémie et sont saisis par le rotor.

-

Découpe et lavage à grande vitesseLe rotor tourne à grande vitesse, cisaillant le matériau contre des lames fixes. L'eau circule dans la chambre de coupe, éliminant les contaminants.

-

Décharge humideLes flocons nettoyés sortent par une vis d'évacuation humide ou un convoyeur pour être lavés ou séchés ultérieurement.

-

Recirculation de l'eauL'eau de process peut être filtrée et recirculée afin de réduire la consommation d'eau.

Les granulateurs humides correctement conçus assurent un débit continu avec un minimum de blocages et une usure réduite.

Caractéristiques clés à rechercher dans les systèmes de granulateurs de plastique humide

Les granulateurs de plastique humide doivent être évalués selon leur durabilité, leur consommation d'énergie et la facilité d'entretien. Leurs principales caractéristiques de conception comprennent généralement :

-

Stabilité du rotor à haute vitesse : Un rotor équilibré assure une coupe uniforme et réduit l'usure liée aux vibrations.

-

Rejet humide efficace : Une vis d'évacuation ou un convoyeur qui élimine rapidement les flocons tout en drainant l'eau libre contribue à stabiliser la manutention en aval.

-

Réserve de puissance et de couple suffisante : Une puissance suffisante empêche l'effondrement de la vitesse sur les plastiques plus résistants et améliore la stabilité du débit.

-

Portez une protection dans les zones humides : Les matériaux et les joints d'étanchéité conçus pour une exposition continue à l'eau réduisent la corrosion et les défaillances prématurées des roulements.

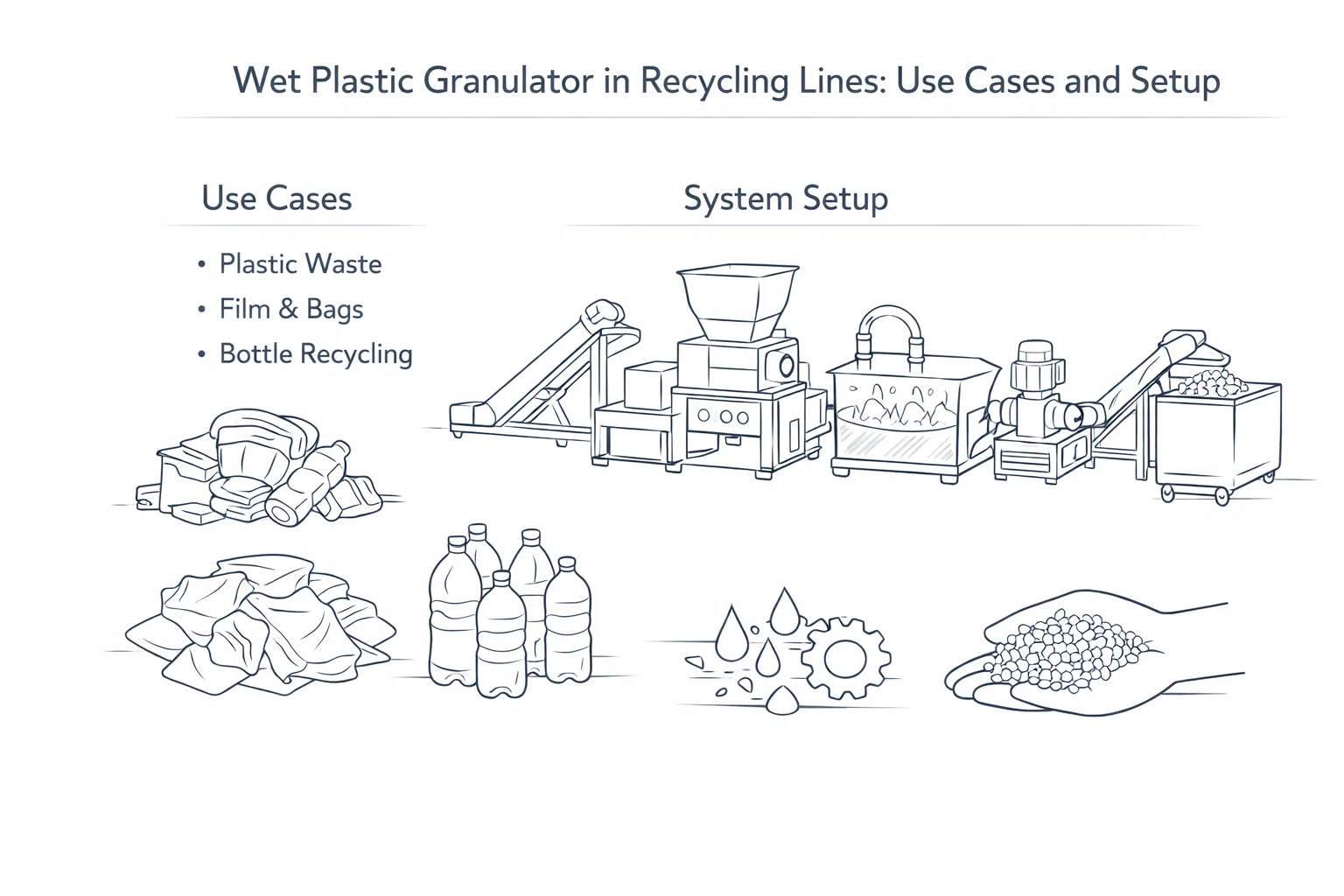

Applications et matériaux compatibles

Les granulateurs humides sont polyvalents et peuvent traiter une grande variété de déchets plastiques, notamment :

-

Bouteilles et récipients en PEHD

-

Caisses et bouchons en PP

-

Film LDPE/LLDPE et film agricole

-

Bouteilles PET (prélavage)

-

Plastiques rigides mélangés avec des étiquettes ou de la saleté

En incorporant de l'eau dans le processus de découpe, ces machines produisent des flocons plus propres, réduisant ainsi la charge des étapes de lavage et de séparation ultérieures.

Conseils d'entretien pour un fonctionnement fiable

Pour assurer le bon fonctionnement de votre granulateur de plastique humide, suivez ces bonnes pratiques :

-

Inspection du rotor et du couteauVérifiez régulièrement le tranchant et l'espacement des lames ; remplacez-les ou ajustez-les si nécessaire.

-

Entretien du système d'eauNettoyez les filtres et les buses de pulvérisation pour maintenir un débit et une pression constants.

-

Lubrification des roulementsRespectez le calendrier de lubrification recommandé afin d'éviter une usure prématurée.

-

Nettoyage d'écran: Veillez à ce que les grilles d'évacuation restent dégagées afin d'éviter toute surchauffe et toute réduction de la production.

-

Vérifier l'accouplement et le moteurVérifiez l'alignement de l'accouplement et la température du moteur afin d'éviter tout dommage.

Un entretien adéquat prolonge la durée de vie des machines, réduit les temps d'arrêt et garantit une qualité de production constante.

Critères de sélection des fournisseurs de granulateurs de plastique humide

Lors du choix d'un fournisseur, privilégiez la fiabilité opérationnelle et le support tout au long du cycle de vie :

-

Configuration adaptée : Possibilité d'adapter la configuration des couteaux, le type de décharge et le débit à votre matériau et à votre agencement.

-

Références documentées : Preuves d'installations et de conditions d'alimentation similaires.

-

Disponibilité des pièces de rechange : Délais de livraison clairs et liste des pièces de rechange critiques recommandées (lames, tamis, roulements, joints).

-

Réponse du service : Assistance à la mise en service, processus de dépannage et conseils de maintenance.

-

Clarté commerciale : Périmètre transparent, hypothèses relatives aux services publics (recirculation de l'eau) et attentes en matière de performance.

Liste de vérification pour l'installation : Intégration d'un granulateur de plastique humide dans une ligne de recyclage

Utilisez cette liste de contrôle pour éviter les goulots d'étranglement et l'usure inutile lors de la mise en service d'un granulateur humide :

-

Position dans la ligne : Généralement après le tri manuel et avant la séparation par flottation ou le lavage par friction, le granulateur effectue une réduction de taille initiale et un rinçage de surface.

-

Pulvérisation d'eau et recirculation : Assurez une couverture de pulvérisation stable dans la chambre de coupe ; ajoutez une filtration (tamis/décantation) avant la recirculation pour empêcher les particules abrasives d'accélérer l'usure des couteaux.

-

Gestion des rejets : Confirmez si vous utiliserez une vis d'évacuation humide ou un convoyeur, et adaptez l'équipement en aval (laveuse à friction, déshydratation ou séchoir centrifuge) au débit de flocons humides.

-

Alignement de la cible de dimensionnement : Sélectionnez le tamis/la perforation en fonction du lavage en aval et des spécifications des flocons de l'acheteur ; un tamisage trop fin augmente la quantité de fines et la charge sur le traitement de l'eau.

-

État de la lame et vérification de l'écartement : Mettez en place une procédure de vérification du tranchant des lames et du dégagement des couteaux avant d'augmenter la cadence de production.

-

Test de mise en service : Effectuez un court essai avec votre matière première la plus défavorable (étiquettes, saletés, variabilité de l'humidité) et vérifiez les flux de rejet et la clarté de l'eau pour valider les paramètres.

Prêt à en savoir plus ?

Si vous envisagez de moderniser votre ligne de recyclage ou de lancer un nouveau projet, il est essentiel de comprendre le rôle de la granulation humide. Pour obtenir des spécifications détaillées et les tarifs, Consultez ici les détails de notre granulateur de plastique humide. Notre équipe se fera un plaisir de vous conseiller sur la configuration la mieux adaptée à vos besoins.

Références

- Energycle — Granulateur de plastique humide

- Energycle — Solutions de recyclage

- Energycle — Contactez-nous

- OSHA — Aperçu de la protection des machines

- OSHA — Contrôle des énergies dangereuses (consignation/étiquetage), 29 CFR 1910.147

- ISO — Lignes directrices sur le recyclage des plastiques (Présentation de la norme ISO 15270)