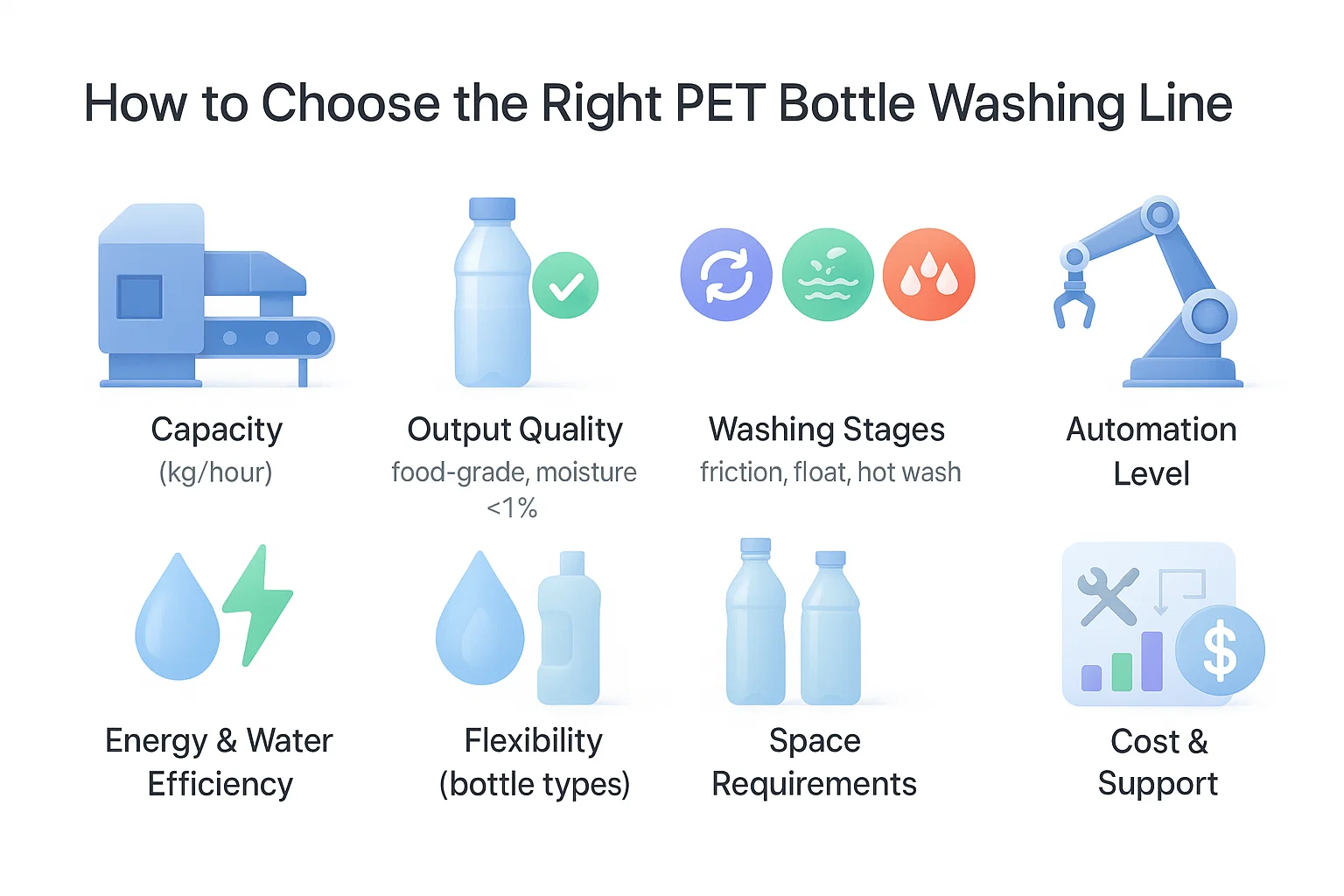

Selecting the right PET bottle washing line is crucial for ensuring efficient production, consistent output quality, and long-term operational success. Whether you’re entering the recycling business or scaling up your current operations, it’s essential to consider several key factors to make an informed decision.

1. Assess Your Processing Capacity

Begin by determining how much PET material—bottles or flakes—you plan to process per hour or per day. Washing lines typically range from 500 kg/h to over 5000 kg/h, with customized solutions reaching 6000 kg/h or more.

Choosing a system that aligns with your actual production needs will help avoid the pitfalls of underutilization or overinvestment.

2. Define the Required Output Quality

Consider whether your end product must meet food-grade standards, which require high purity and additional processing steps such as hot washing and advanced sorting.

Ensure the system consistently delivers flakes with low moisture content (below 1%) and minimal contamination, especially PVC, labels, or metals.

3. Examine Washing Efficiency and Technology

Efficient washing lines use a multi-stage process to maximize cleanliness and quality. Look for systems that include:

- Friction washing

- Float-sink separation

- Hot washing

- Density separation

These technologies reduce the need for reprocessing and help maintain high-quality output.

4. Consider Automation and User-Friendliness

Automation can significantly improve operational consistency and reduce labor costs. However, higher automation levels may come with increased initial investment.

Select a system that balances automation with your team’s technical skills and maintenance capabilities.

5. Evaluate Energy and Water Efficiency

Choose equipment designed to minimize energy and water usage, which directly impacts your long-term operating costs.

Modern washing lines often include closed-loop water systems and energy-efficient motors to enhance sustainability and reduce waste.

6. Ensure Flexibility and Adaptability

If your input materials vary—different bottle sizes, colors, or contamination levels—opt for a system that can adapt to diverse feedstock.

Versatile lines improve ROI and help you remain responsive to evolving market demands.

7. Account for Space and Installation Requirements

Carefully assess your facility’s layout and select equipment that fits your available space. Many manufacturers offer customized layouts to optimize floor space and workflow without compromising performance.

8. Compare Costs and After-Sales Support

While upfront equipment cost is important, also consider:

- Performance metrics

- Warranty terms

- Maintenance and parts availability

- Quality of after-sales service

Choosing a reliable supplier ensures long-term operational continuity and reduces downtime.

✔ Summary Checklist: Choosing the Right PET Bottle Washing Line

- Capacity: Align with your expected processing volume (e.g., 500–5000+ kg/h).

- Output Quality: Ensure compliance with purity standards (food-grade if necessary).

- Washing Efficiency: Look for comprehensive, multi-stage cleaning systems.

- Automation: Choose automation based on budget and workforce capabilities.

- Resource Consumption: Opt for systems with low energy and water usage, preferably with recycling features.

- Flexibility: Ensure the line can handle varying input materials.

- Space Requirements: Confirm the system fits within your facility without disruption.

- Total Cost of Ownership: Balance purchase cost, efficiency, maintenance, and service.

By thoroughly evaluating these aspects in light of your business objectives, you can invest in a PET bottle washing line that enhances production efficiency, product quality, and cost-effectiveness, ensuring both immediate and long-term success.