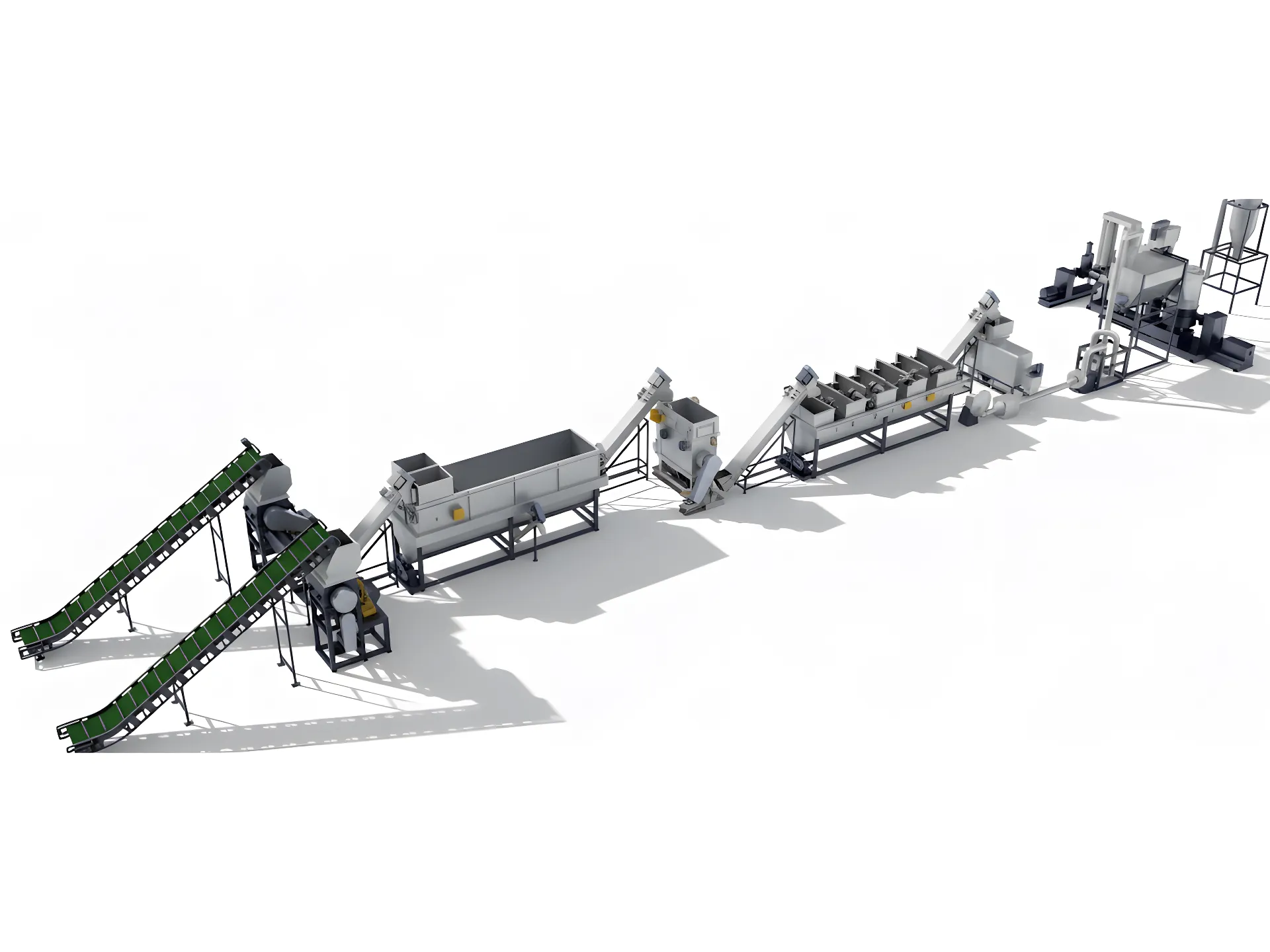

PP/PE Plastic Film Shredding & Densifying Washing Line

From bale to clean, dense pellets/flakes. Process 200–1000 kg/h with stable moisture and high bulk density — engineered for heavily contaminated films.

Why This Line Excels

Integrated, efficient, and configurable — delivering clean, dense output suitable for transport and downstream processing.

End-to-End Efficiency

Continuous flow from bale shredding to densified output, minimizing handling and downtime.

High Bulk Density

Achieve approximately 350–410 kg/m³ with stable moisture for easier transport and feeding.

Contamination Ready

Wet granulation and sink/float separation remove mud, stones, paper, and light labels.

Process Flow

Bale Shredding

Single-shaft shredder opens compacted PP/PE film bales and reduces them into manageable pieces.

Wet Granulation

High-speed wet granulator cuts into uniform flakes while pre-washing and screening for size.

Sink/Float Separation

Density separation removes heavy contaminants; floating film is collected for drying and densifying.

Squeeze & Densify

Powerful squeezer-densifier dewaters and compacts film into dense flakes/pellets ideal for feeding.

Applications

Material Types

PP woven bags, PE film, LDPE/LLDPE packaging film, agricultural film (after pre-sorting), stretch film.

Output Use

Feeding extruders/pelletizers, wash lines, agglomerators, or direct sale as densified flakes.

Contamination

Handles soil, paper, labels, and moisture with robust washing and separation stages.

Technical Specifications

| Throughput Options | 200–300 kg/h · 500–700 kg/h · up to 1000 kg/h |

|---|---|

| Output Form | Densified flakes / irregular pellets |

| Bulk Density | Approx. 350–410 kg/m³ |

| Final Moisture | Typically ≤ 3–5% (material-dependent) |

| Power Demand | Approx. 120–350 kW depending on configuration |

| Water System | Closed-loop with filtration and optional DAF |

| Controls | PLC with HMI; safety interlocks and overload protection |

| Footprint | Modular, configurable layout to suit plant space |

What’s Included

Shredder + Conveyor

Single-shaft shredder with hydraulic pusher and wear-resistant cutters.

Wet Granulator

High-speed cutting, integrated screen, water flushing for pre-wash.

Sink/Float Tank

Effective density separation with skimming and sludge discharge.

Friction Washer

Optional intensive cleaning and surface dirt removal.

Squeezer-Densifier

Screw pressing and compaction for moisture reduction and bulk density.

Electrical & Piping

PLC controls, interlocks, water loop plumbing, and installation guidance.

FAQs

What capacity should I choose?

Select based on incoming bale volume, contamination, and staffing. Modular lines from 200 to 1000 kg/h with upgrade paths.

How clean is the final output?

With wet granulation, sink/float, and optional friction/hot washing, you can reach ≤ 3–5% moisture and low impurity levels suitable for pelletizing.

Can it handle agricultural film?

Yes, with pre-sorting and optional modules (stone trap, hot wash). Heavily soiled films may reduce throughput slightly.

Do you provide installation and training?

Yes. We provide layout design, commissioning support, and operator training with remote/onsite options.

Get a Quote

Tell us your material types, contamination level, and desired throughput. We’ll tailor a solution and layout drawing.