Il ruolo essenziale dei granulatori di plastica nel riciclaggio moderno

I granulatori di plastica sono il fulcro di qualsiasi sistema di riciclaggio della plastica efficace. Lavorano in sinergia con altri macchinari specializzati per trasformare i rifiuti plastici ingombranti in una risorsa preziosa e riutilizzabile. Comprendere la loro funzione è fondamentale per comprendere l'intero processo di riciclo. Scopriamo come questi potenti macchinari si inseriscono in una soluzione completa ed efficiente per affrontare il problema dei rifiuti plastici.

Fase 1: Pre-elaborazione – Preparazione della plastica per la granulazione

Prima che un granulatore di plastica possa fare la sua magia, il materiale di scarto grezzo deve essere preparato. Questa fase iniziale in genere prevede un trituratore di plastica.

Perché triturare prima? La distinzione tra trituratore e granulatore

Una domanda comune è: qual è la differenza tra un trituratore e un granulatore?

- Trituratori di plastica: Si tratta di macchine a bassa velocità e alta coppia, progettate per smantellare in modo aggressivo oggetti di plastica di grandi dimensioni, pesanti o densi. Immaginateli come la squadra di demolizione principale, che scompone oggetti come paraurti di auto, bidoni della spazzatura, tubi e grandi scarti di plastica in pezzi più piccoli, ruvidi e gestibili.

- Granulatori di plastica: Si tratta di macchine ad alta velocità e bassa coppia che utilizzano lame affilate con un'azione di taglio simile a quella delle forbici. Prendono i pezzi di plastica pre-triturati e li raffinano in particelle piccole e di dimensioni uniformi, note come "rimacinato" o "scaglie".

L'utilizzo di un trituratore prima del granulatore svolge due funzioni fondamentali:

- Aumenta l'efficienza: Riduce notevolmente lo sforzo a cui è sottoposto il granulatore, consentendogli di funzionare in modo molto più efficiente.

- Prolunga la durata della macchina: Protegge le lame di precisione del granulatore da danni e usura eccessiva, garantendone una maggiore durata operativa.

Fase 2: Granulazione – Creazione di scaglie di plastica uniformi

Questo è dove il macchina granulatore di plastica Il centro dell'attenzione. Spesso chiamate trituratrici di plastica, queste macchine sono il cuore del processo di riduzione dimensionale. All'interno della camera di taglio, lame rotanti ad alta velocità lavorano contro lame fisse per tagliare la plastica pre-triturata in scaglie uniformi.

La dimensione e la qualità di questo macinato sono cruciali, in quanto determinano l'efficienza delle successive fasi di riciclaggio. La nostra gamma di Granulatori di plastica è progettato per gestire un'ampia gamma di materie plastiche, dalle bottiglie in PET e pellicole di plastica ai polimeri rigidi di grado ingegneristico, garantendo ogni volta un output costante e di alta qualità.

Fase 3: Pulizia – Purificazione del macinato

Una volta granulate, le scaglie di plastica devono essere accuratamente pulite. Questo è un passaggio fondamentale per rimuovere contaminanti come sporco, etichette di carta, adesivi e residui di cibo, che possono compromettere la qualità del materiale riciclato finale.

Per questo compito vengono in genere utilizzate lavatrici a frizione ad alta velocità. Tuttavia, per un processo più snello ed efficiente, molti impianti moderni utilizzano granulatori di plastica bagnatiQuesti sistemi avanzati introducono l'acqua direttamente nella camera di taglio, offrendo diversi vantaggi chiave:

- Pulizia simultanea: L'acqua lava la plastica mentre viene granulata.

- Riduzione di attrito e calore: L'acqua agisce da lubrificante e refrigerante, impedendo alla plastica più morbida di sciogliersi e prolungando la durata delle lame.

- Abbattimento della polvere: Riduce notevolmente la polvere nell'ambiente di lavorazione.

Questo approccio integrato garantisce un macinato più pulito e di qualità superiore, pronto per la trasformazione finale.

Fase 4: Ulteriore lavorazione – Dai fiocchi ai pellet

Dopo essere stati lavati e asciugati, i fiocchi di plastica puliti passano alla fase finale del loro percorso di riciclaggio. Questo in genere comporta un macchina per la pellettizzazione della plasticaQuesta macchina fonde i fiocchi e li estrude attraverso una filiera, creando piccole palline uniformi (note anche come "nurdles").

Perché i pellet sono la forma preferita? Le loro dimensioni e la loro forma costanti li rendono incredibilmente facili da maneggiare, trasportare e, soprattutto, da alimentare con macchinari di produzione come stampatori a iniezione ed estrusori. Questi pellet sono la materia prima per creare nuovi prodotti in plastica, chiudendo il ciclo del riciclo.

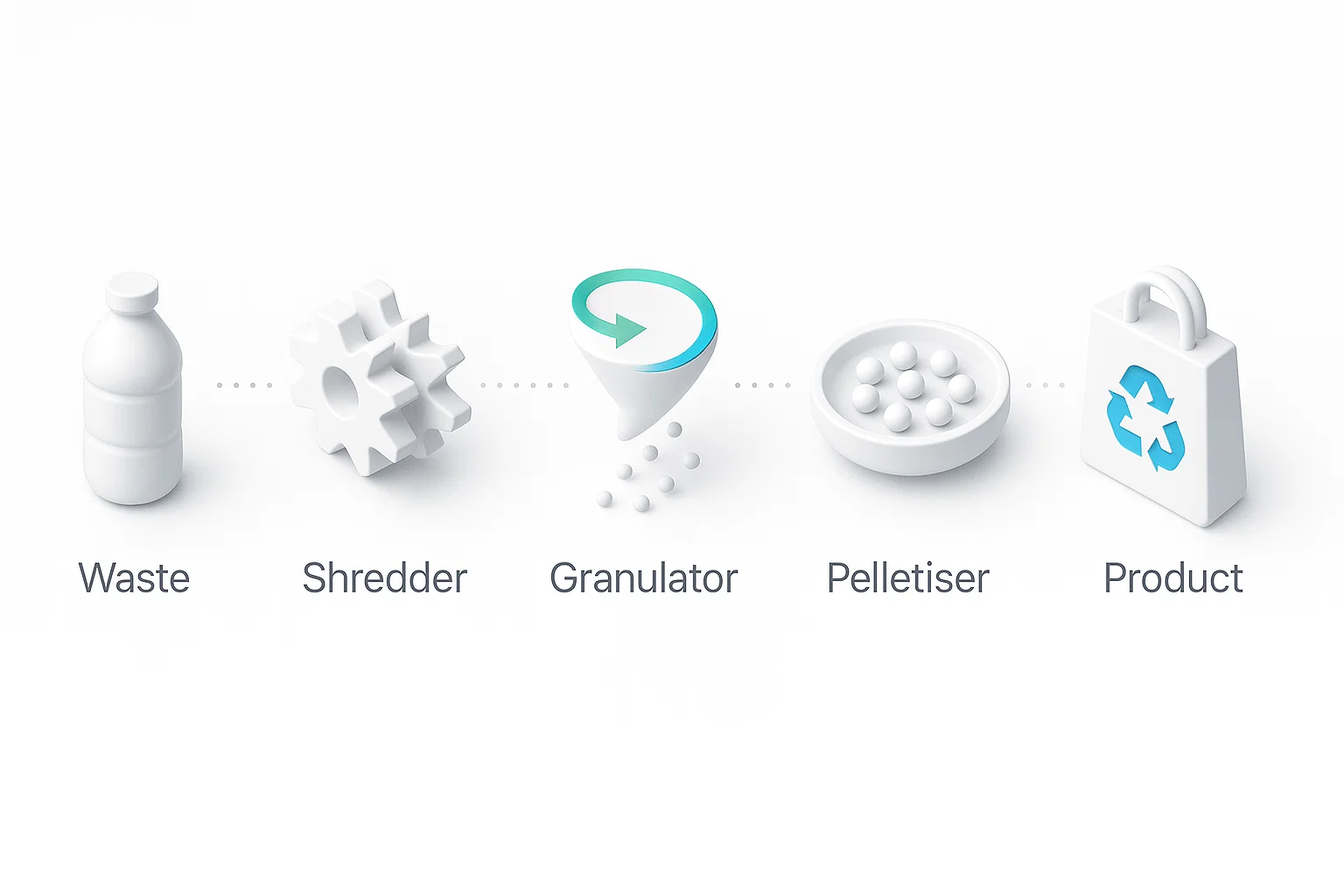

Una soluzione completa per il riciclaggio della plastica: come funziona tutto insieme

Integrando trituratori, granulatori, sistemi di lavaggio e pellettizzatori, si crea una linea di riciclaggio della plastica omogenea e altamente efficace. Ogni macchina svolge un ruolo specifico e fondamentale.

| Macchina | Funzione primaria | Ingresso | Produzione |

| Trituratore di plastica | Riduzione grossolana delle dimensioni di oggetti ingombranti | Grandi parti in plastica, balle | Pezzi più piccoli e ruvidi |

| Granulatore di plastica | Riduzione fine delle dimensioni in particelle uniformi | Pezzi pre-triturati | Piccoli fiocchi o 'rimacinati' |

| Sistema di lavaggio | Rimuove i contaminanti | Scaglie di plastica sporche | Scaglie di plastica pulite |

| Pellettizzatore di plastica | Crea nuova materia prima | Fiocchi puliti e asciutti | Pellet di plastica uniformi |

Questo sistema integrato fornisce una soluzione completa in grado di gestire qualsiasi cosa, dagli imballaggi post-consumo come le bottiglie in PET alle plastiche industriali rigide.

Domande frequenti (FAQ)

D: Un granulatore può gestire autonomamente pezzi di plastica di grandi dimensioni?

R: Sebbene alcuni granulatori per impieghi gravosi possano gestire pezzi più grandi, è generalmente molto più efficiente ed economico utilizzare un trituratore per la riduzione iniziale delle dimensioni. Questo previene inceppamenti, riduce l'usura del granulatore e si traduce in una granulometria finale più uniforme.

D: Che cosa si intende per "rimacinato"?

R: Rimacinato è il termine utilizzato per indicare le piccole particelle di plastica riciclata prodotte da un granulatore. Può essere miscelato con plastica vergine o utilizzato da solo per produrre nuovi prodotti.

D: I granulatori a umido sono sempre migliori?

R: Per i rifiuti post-consumo contaminati o le plastiche sensibili al calore, i granulatori a umido offrono vantaggi significativi in termini di pulizia ed efficienza. Per gli scarti industriali puliti, gestiti internamente, un granulatore a secco può essere perfettamente sufficiente.

Conclusione: la pietra angolare dell’economia circolare

I granulatori di plastica sono molto più di semplici apparecchiature per la riduzione delle dimensioni: sono fondamentali per il successo dell'economia circolare. Lavorando in tandem con trituratori, lavatrici e pellettizzatori, forniscono il collegamento cruciale che trasforma i rifiuti plastici problematici in un materiale riutilizzabile di alta qualità. Questo processo non solo evita che la plastica finisca in discariche e oceani, ma riduce anche la nostra dipendenza dalle risorse vergini, aprendo la strada a un futuro più sostenibile.