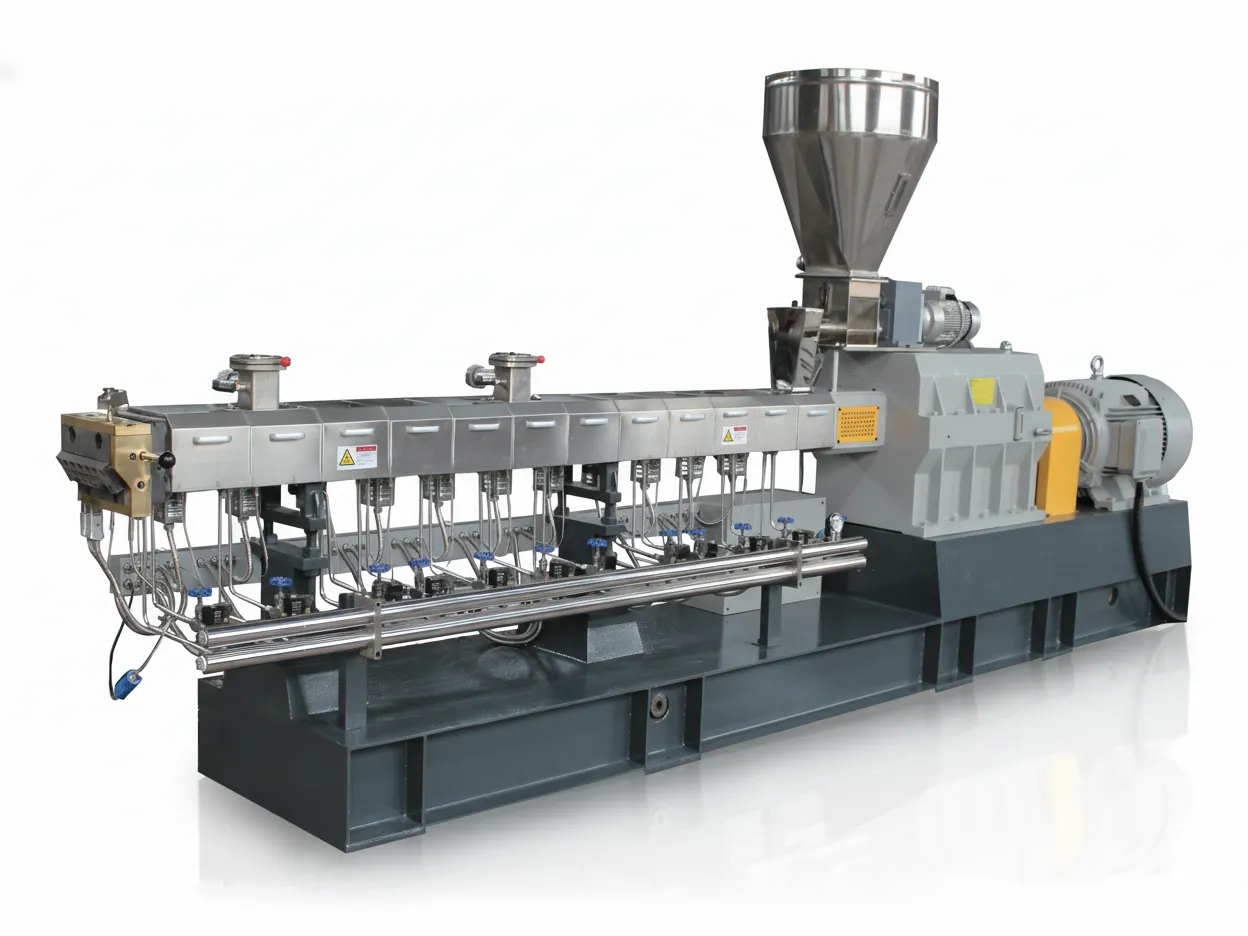

Linea di estrusione e pelletizzazione a doppia vite

Progettato appositamente per la miscelazione, la compoundazione, la devolatilizzazione e l'estrusione stabile, ideale per masterbatch, compound caricati, miscele di polimeri e compound riciclati di alto valore.

Richiedi un preventivoProgettato per la compoundazione, non solo per l'estrusione

A differenza di un estrusore bivite generico che spinge principalmente una massa fusa precomposta, questa linea è progettata per disperdere uniformemente riempitivi e additivi, rimuovere le sostanze volatili tramite sfiato/vuoto e fornire pellet di qualità costante con filtrazione e pellettizzazione integrate.

Vantaggi del grado di compounding

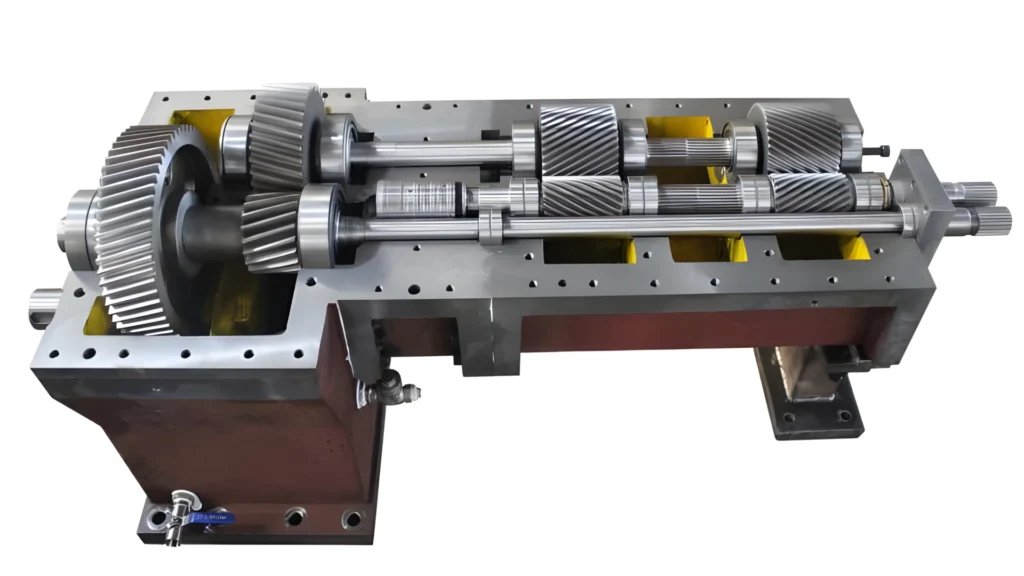

Miscelazione ad alta intensità

Gli elementi a vite ottimizzati garantiscono una forte miscelazione dispersiva e distributiva per proprietà composte stabili.

Alimentazione di precisione

Supporta alimentatori gravimetrici/volumetrici, alimentazione laterale e dosaggio personalizzato per riempitivi, fibre e additivi.

Controllo della devolatilizzazione

Le opzioni di ventilazione e aspirazione rimuovono l'umidità e le sostanze volatili, ottenendo pellet più puliti e con meno difetti.

Filtrazione e pellettizzazione integrate

Il cambiafiltro idraulico e le opzioni di pellettizzazione (a filamenti o ad anello liquido) stabilizzano la qualità e la resa.

In che modo differisce da un estrusore a doppia vite standard

Ideale per estrusione semplice

Spesso utilizzato per fondere e trasportare materiali già ben preparati o precomposti.

- Dispersione limitata con elevato carico di riempitivo/additivo

- Meno zone di miscelazione dedicate (sfiato, vuoto, alimentazione laterale)

- Le apparecchiature a valle possono essere esterne o non integrate

- Maggiore rischio di variazione da lotto a lotto per ricette complesse

Progettato per miscelazione + compounding + estrusione

Progettato per trasformare resina + riempitivi + additivi in un composto omogeneo, per poi pellettizzarlo con un controllo di qualità stabile.

- Moduli vite/cilindro configurabili per miscelazione dispersiva e distributiva

- Opzioni di alimentazione per polveri, fibre, liquidi e alimentazione laterale

- Sfiato/vuoto per rimuovere le sostanze volatili e migliorare l'aspetto del pellet

- Filtrazione integrata + pellettizzazione per pellet più puliti e uniformi

Il flusso di lavoro di miscelazione-composizione-estrusione

- Alimentazione e dosaggio: Resina e additivi vengono dosati con precisione (alimentatore principale + alimentatore laterale, secondo necessità).

- Miscelazione intensiva: Gli elementi a vite disperdono i riempitivi/pigmenti e distribuiscono gli additivi in modo uniforme nella massa fusa.

- Sfiato / Vuoto: L'umidità e le sostanze volatili vengono rimosse per migliorare la stabilità e ridurre bolle/odori.

- Filtrazione a fusione: Un cambiafiltro idraulico cattura i contaminanti per un flusso di fusione pulito e stabile.

- Pellettizzazione: Scegliere la pellettizzazione a filamenti o ad anello d'acqua in base al polimero e ai requisiti a valle.

- Raffreddamento e movimentazione: I pellet vengono raffreddati, essiccati (se necessario) e trasportati per lo stoccaggio o il confezionamento.

Applicazioni di compounding ad alto valore

Produzione di Masterbatch

Masterbatch colorante/additivo/riempitivo ad alta concentrazione con dispersione uniforme e qualità ripetibile.

Composti riempiti e rinforzati

Ottimizzato per minerali (CaCO₃, talco) e rinforzo in fibra con produttività stabile e controllo della fusione.

Composti riciclati

Migliora la consistenza dei flussi riciclati con devolatilizzazione e filtrazione per pellet più puliti.

Compounding reattivo/funzionale

Supporta zone di miscelazione controllate per formulazioni speciali e additivi funzionali.

Parametri tecnici principali

| Linea | Estrusore | Diametro della vite (mm) | Velocità del Serraggio (rpm) | Potenza motore (kW) | Capacità (kg/h) |

|---|---|---|---|---|---|

| GTS52/120 | GTE52 | 51.4 | 600 | 55–75 | 180–260 |

| SJ120 | 120 | 85 | |||

| GTS65/150 | GTE65 | 62.4 | 600 | 90–110 | 260–350 |

| SJ150 | 150 | 85 | |||

| GTS75/180 | GTE75 | 71 | 600 | 132–160 | 450–550 |

| SJ180 | 180 | 85 | |||

| GTS95/200 | GTE95 | 93 | 600 | 185–200 | 650–750 |

| SJ200 | 200 | 85 |

*Le specifiche possono variare in base alla formulazione e alla configurazione. Contattateci per una soluzione personalizzata.

Vetrina delle macchine

Guardalo in azione

Uno sguardo veloce al flusso di lavoro di compounding e pellettizzazione.

Garanzia e installazione

Garanzia limitata di 1 anno

Tutti i nostri sistemi di riciclaggio e miscelazione includono una garanzia limitata completa di un anno.

Supporto e personalizzazione dei processi

Forniamo consulenza sulla configurazione delle viti, supporto all'installazione e servizio post-vendita per soddisfare le vostre esigenze di formulazione e di produzione.

Domande frequenti

Cosa differenzia questa linea di compounding da un normale estrusore bivite?

Questo sistema è configurato per la miscelazione, la devolatilizzazione, la filtrazione e la pellettizzazione, in modo da poter trasformare in modo affidabile resina + riempitivi/additivi in un composto omogeneo. Un estrusore standard è spesso incentrato sulla semplice estrusione di materiale già preparato.

Potete supportare formulazioni ad alto contenuto di riempitivo o fibra di vetro?

Sì. Con i giusti alimentatori ed elementi a coclea, la linea può gestire composti rinforzati e caricati con minerali. La capacità e il carico raggiungibile dipendono dalla formulazione, dalla granulometria e dalla stabilità del dosaggio: condividete la vostra ricetta per una configurazione consigliata.

Come faccio a scegliere la pellettizzazione a filamenti rispetto alla pellettizzazione ad anello d'acqua?

La pellettizzazione a filamento è robusta e ampiamente utilizzata per molti composti. La pellettizzazione ad anello d'acqua è compatta ed efficiente per flussi di fusione stabili. Consigliamo il metodo in base al tipo di polimero, alla produttività e ai requisiti di qualità dei pellet.

Fornite supporto per la configurazione e la messa in servizio delle viti?

Sì. Possiamo consigliare configurazioni di viti/cilindri e fornire assistenza all'installazione, supporto all'avviamento e consigli sulla manutenzione per aiutarti a raggiungere rapidamente una produzione stabile.

Quali input sono necessari per dimensionare correttamente la linea?

Si prega di specificare il tipo di polimero, le percentuali di riempitivo/additivo, la capacità desiderata (kg/h), il livello di umidità/contaminazione e il metodo di pellettizzazione desiderato. Indicheremo le dimensioni dell'estrusore, gli alimentatori, la filtrazione e le apparecchiature a valle.

Richiedi un preventivo per la tua linea di compounding

Comunicaci la tua formulazione e la capacità desiderata: il nostro team ti consiglierà gli alimentatori, la configurazione della coclea, la filtrazione e la configurazione di pellettizzazione più adatti.