Il trituratore monoalbero definitivo per gli scarti dell'estrusore

Trasforma senza sforzo gli ostinati scarti della testa dell'estrusore in materiali preziosi e riutilizzabili con la nostra soluzione di triturazione affidabile e robusta.

Richiedi un preventivoProgettato per prestazioni e durata

Gruppo propulsore robusto

È dotato di un riduttore serie H ad alta coppia e di un albero principale solido, realizzato in un unico pezzo, che assicura un'erogazione di potenza costante per triturare anche i materiali più resistenti.

Lame convenienti

I nostri esclusivi coltelli mobili a quattro angoli possono essere ruotati per utilizzare un nuovo bordo affilato, prolungandone notevolmente la durata e riducendo i costi di manutenzione.

Protezione intelligente

L'avanzato sistema di controllo PLC include un meccanismo di ritorno automatico in caso di sovraccarico, prevenendo danni e garantendo un'affidabilità operativa a lungo termine.

Dai rifiuti alla materia prima in quattro semplici passaggi

Alimentazione del materiale

Un cilindro idraulico garantisce una velocità di alimentazione costante e controllata, spingendo in modo costante i rifiuti dell'estrusore nella camera di triturazione.

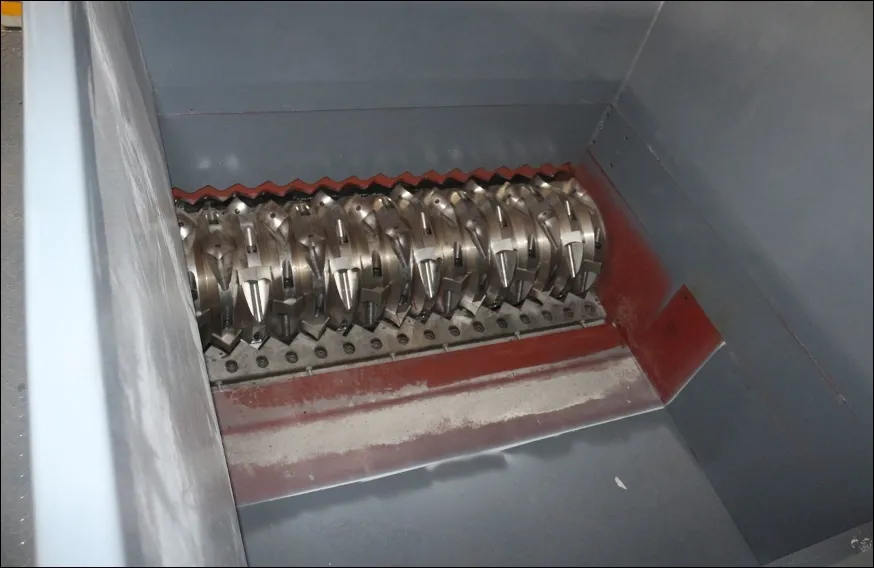

Triturazione efficiente

Le lame rotanti in lega di acciaio ad alta resistenza lavorano in sinergia con le lame fisse per tagliare il materiale in pezzi più piccoli e uniformi.

Controllo PLC

Il sistema monitora il carico del motore. Se viene rilevato un sovraccarico, l'albero inverte automaticamente la rotazione per risolvere l'inceppamento prima di proseguire.

Produzione di materiale

Il materiale triturato passa attraverso un setaccio (opzionale), garantendo una granulometria uniforme, pronto per la fase successiva del riciclaggio.

Guarda The Shredder in azione

Scoprite voi stessi come il nostro trituratore monoalbero lavora in modo efficiente le plastiche industriali più resistenti. Questo video dimostra la potenza della macchina, il suo funzionamento fluido e la qualità del risultato finale triturato.

Caratteristiche dettagliate e specifiche tecniche

Assemblea principale

Il cuore della macchina è costruito su un robusto telaio con un solido albero rotante lavorato a CNC. Il tutto è completato da una sede esterna per cuscinetti di un rinomato marchio nazionale (Wafangdian) per una maggiore stabilità e facilità di manutenzione.

Potenza e controllo

Azionato da un potente motore da 22 kW e da un riduttore a denti permanenti serie H, il trituratore raggiunge una velocità di rotazione stabile di 81 giri/min. L'intera operazione è gestita da un sistema PLC Delta con componenti elettrici Siemens e Schneider di alta qualità, per un'affidabilità senza pari.

Sistema idraulico

Il sistema idraulico da 3 kW alimenta il carrello di alimentazione del materiale, erogando una pressione fino a 21 MPa. Ciò garantisce una velocità di avanzamento stabile e regolabile. Il sistema è mantenuto a temperatura ottimale da un efficiente meccanismo di raffreddamento ad aria.

| Articolo | Parametro | Descrizione |

|---|---|---|

| Modello | Modello RTM-SD2360 | Trituratore monoalbero |

| Produzione | 200-300 kg/ora | Dipende dal tipo di materiale e dalle dimensioni dello schermo. |

| Camera di triturazione | 550 mm x 580 mm | Area di lavoro efficace per la lavorazione dei materiali. |

| Sistema di taglio | 30 mobili, 1 lama fissa | Lame in lega di acciaio SKD-11 (40x40 mm) su un albero dal diametro di 230 mm. |

| Potenza del motore principale | 22 kW | Marchio automobilistico nazionale affidabile. |

| Potenza idraulica | 3 kW | Alimenta il pistone di alimentazione del materiale. |

Galleria delle macchine

Ottieni una soluzione e un preventivo personalizzati

I nostri esperti sono pronti ad aiutarti a configurare il distruggidocumenti perfetto per le tue esigenze specifiche. Contattaci oggi stesso per ricevere informazioni aggiornate su prezzi e tempi di consegna.