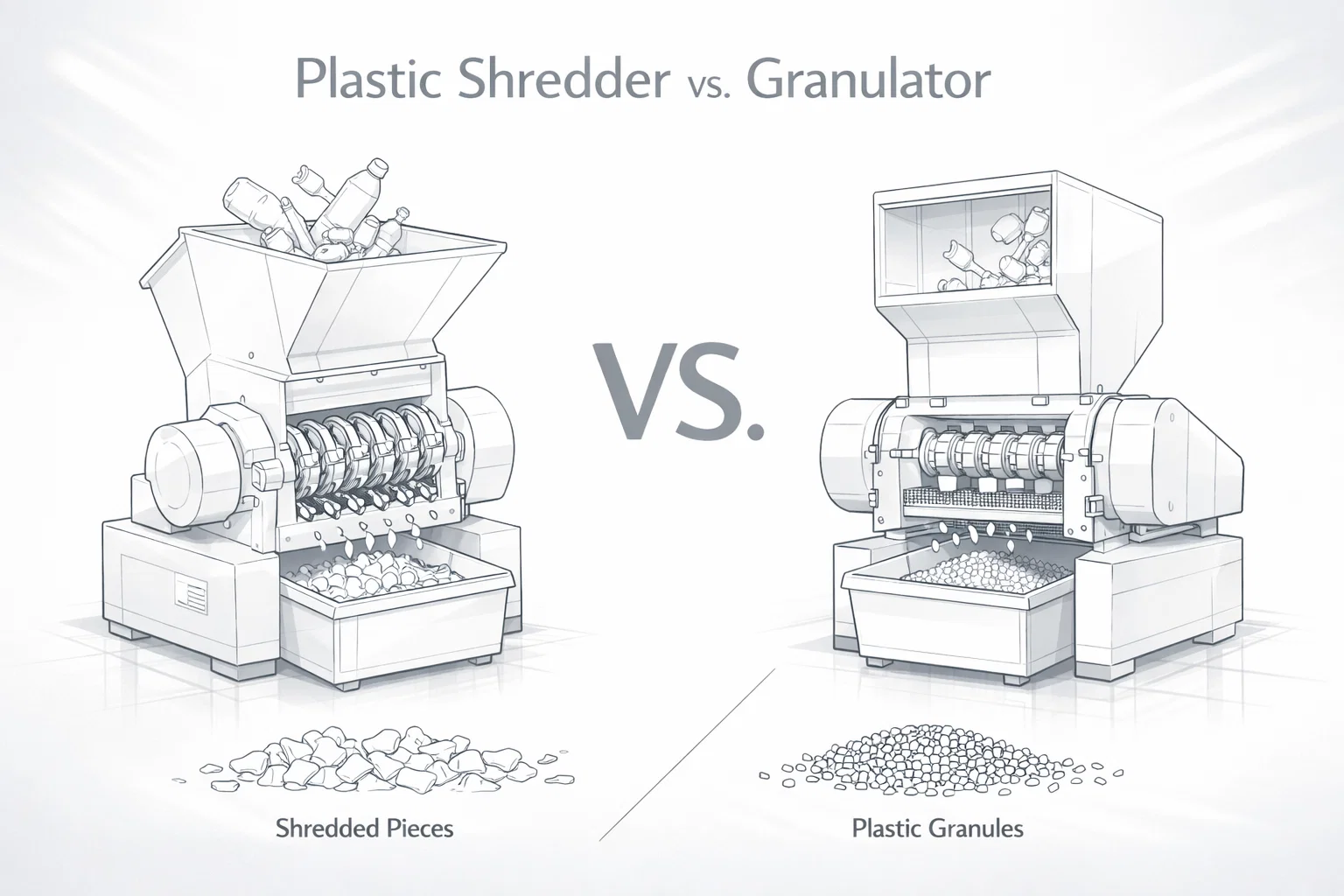

“Shredder” and “granulator” get used interchangeably in plastics recycling conversations, but they solve different problems. In a rigid recycling line, your first-stage choice affects feeding stability, knife life, dust generation, washing performance, and extrusion consistency.

This guide explains the difference in practical engineering terms, then turns it into a buying checklist you can use when you size a line.

Belangrijkste punten

- Use a shredder for bulky, thick, hollow, or irregular parts that will not feed evenly.

- Use a granulator to make a more uniform flake for washing, drying, and extrusion.

- Many rigid lines run a shredder first, then a granulator as the sizing step.

- Treat metal control as part of the system design; granulators are less forgiving.

Shredder vs. Granulator: A Practical Definition

In rigid plastics recycling, people typically mean the following:

- Shredder (low-speed, high-torque): A primary reducer that turns awkward 3D parts into manageable pieces and stabilizes feeding.

- Granulator (high-speed knife mill): A sizing machine that turns consistently fed input into a more uniform flake.

You may also hear “crusher” used for a granulator-style machine. What matters is the cutting style (high-speed knife cutting vs. low-speed shear) and how sensitive the machine is to feeding and contamination.

What a Single Shaft Shredder Does Well

A single shaft shredder is designed for controlled size reduction under high torque:

- A hydraulic pusher loads material into the rotor, so the machine does not rely on gravity feed.

- The cutting action is a shearing process between rotor knives and a counter knife.

- Output size is usually controlled with a screen basket; material stays in the chamber until it passes.

Typical use cases

– thick-walled parts, purge, profiles, drums, bulky scrap

– feedstock with variable shape that tends to bridge or “float” in hoppers

What it changes for your line

– Stabilizes downstream processes by smoothing out feed surges.

– Reduces the need for manual pre-cutting, which lowers handling risk.

– Handles hollow parts and mixed shapes more predictably than a gravity-fed cutter.

What a Granulator Does Well

A kunststof granulator is a sizing machine built for consistent flake geometry:

- High-speed cutting produces more uniform flakes when the input feeds consistently.

- Uniform flakes usually wash and dry more consistently than mixed-size chunks.

- Granulators are commonly used after shredding, or directly on thin-to-medium rigid parts.

Typical use cases

– bottles, crates, injection parts, and pre-shredded rigid scrap

Where granulators struggle

– Inconsistent feeding: large hollow parts can bounce and reduce cutting efficiency.

– Tramp metal: small metal pieces can damage knives quickly.

– Very thick sections: heavy parts may cut slowly and create more fines and heat.

Side-by-Side Comparison (Line-Design View)

| Decision Point | Enkelvoudige as-shredder | Granulator |

|---|---|---|

| Best role in the line | Primary size reduction and feed stabilization | Final sizing into more consistent flakes |

| Material feeding | Hydraulic pusher forces material into the rotor | Typically gravity feed or assisted feed |

| Output control | Screen basket defines maximum piece size | Screen plus cutting geometry defines flake size |

| Handling irregular 3D parts | Strong (pusher + low-speed shear) | Limited unless the feed is consistent |

| Sensitivity to tramp metal | Higher tolerance, but still requires protection | Lower tolerance; metal can damage knives and rotor quickly |

| Dust / fines control | Typically lower fines at the first stage | Can generate more fines if fed poorly or oversized |

| Common downstream step | Granulation, washing, and drying | Washing or direct feed to extrusion (depending on cleanliness) |

| Knife maintenance pattern | Fewer knives, slower wear; depends on contamination | More knives at higher speed; sharper edges matter more |

How to Choose (What Buyers Actually Decide)

Use these questions to decide whether you need a shredder, a granulator, or both.

1) What does your feedstock look like at the infeed?

- Bulky, thick, hollow, or irregular (crates, drums, bumpers, profiles, purge, mixed rigid): start with a shredder.

- Consistent pieces that feed smoothly (pre-cut parts, small injection parts, sorted bottles): a granulator may be enough.

2) What does your downstream process require?

- Washing line + extrusion: more uniform flake size supports steadier washing, drying, and melt filtration.

- Direct densifying / storage only: you may prioritize safe breakdown and throughput stability over final flake geometry.

3) How contaminated is the feed?

If you see metal clips, screws, or occasional parts with embedded fasteners, plan your protection first:

- magnetic separation for ferrous metal

- detection or separation for non-ferrous when the risk justifies it

- inspection access and fast knife service so operators can recover quickly after a contamination event

Granulators often suffer damage faster when metal slips through, so protection is not optional if your feed is uncertain.

When You Need Both

Many rigid recycling plants run a two-step approach:

- Shredder for controlled breakdown of bulky parts into manageable pieces

- Granulator to create defined flakes suitable for washing and extrusion

This setup often stabilizes feeding, reduces manual cutting, and makes downstream process settings easier to hold.

Typical Rigid Line Configurations (Examples)

Bottle / crate regrind for washing and pelletizing

- Granulator as the main cutter (when the infeed is consistent)

- Optional shredder upstream if you receive bales, large crates, or mixed rigid

Bulky parts (drums, bumpers, thick-walled parts, purge)

- Shredder first to control cutting and prevent feed stalls

- Granulator second for flake sizing before washing and extrusion

Mixed rigid collection stream (variable size + occasional contamination)

- Shredder first + stronger metal control upstream

- Granulator second only after you stabilize the infeed

If you are building a line for bottles, bumpers, crates, or mixed rigid feedstock, Energycle can help you configure a complete rigid plastic recycling solution around your target output.

What to Send in an RFQ (So You Get a Useful Quote)

If you ask suppliers for “a shredder” or “a granulator” without specifics, you will get generic specs that do not reflect your real scrap stream. A better RFQ includes:

- plastic type(s): PP, HDPE, PVC, ABS, PC, etc.

- part type and dimensions (photos help), plus wall thickness range

- contamination profile (metal risk, sand/stone, labels, moisture)

- target output size (maximum piece size after shredding, final flake size after granulation)

- target throughput (kg/h) and operating hours per day

- downstream steps (washing, drying, extrusion, storage) and any melt filtration constraints

- site constraints (power supply, noise limits, dust control approach, space)

Safety and Risk Control

These machines store energy, expose rotating cutters, and can eject fragments if misused. Build your selection and SOPs around established safety guidance:

- Machine guarding: Design access doors, interlocks, and safe distances around cutting chambers and belts. See OSHA machine guarding guidance.

- Lockout/tagout: Treat blade changes and jam clearing as energy-control tasks. See OSHA lockout/tagout guidance.

- Recycling operations context: ISO 15270 provides general guidance for plastics recovery and recycling operations. See ISO 15270 overview.

FAQ (Buyer Questions)

Can I skip the shredder and run a granulator on thick rigid parts?

Sometimes, but only if the input feeds smoothly and you accept slower, less stable output. Thick, hollow, or irregular parts tend to roll and bounce in a gravity-fed cutting chamber. That behavior raises amp draw, creates more fines, and increases knife wear. If you receive a wide mix of rigid scrap (crates plus drums plus purge), a shredder often pays back by stabilizing infeed and protecting the granulator from shock loads. If your material is consistent and pre-cut, a heavy-duty granulator can work as a single-stage solution.

What output size should I target for a rigid washing line?

Target a flake size that your washers and dryers can handle without bridging, carryover, or unstable float/sink separation. Smaller flake increases surface area, which can help washing, but it can also increase fines and yield loss if you go too small for your equipment and material mix. Many lines use two stages: first reduce to manageable pieces, then granulate to a more uniform flake that matches the wash line design window. If you already have washer specs, match the flake target to those constraints instead of guessing a number.

How do I protect knives from tramp metal in rigid scrap?

Start with incoming inspection and clear supplier rules, then add hardware upstream. Use magnets for ferrous metal, and consider detection or separation for non-ferrous when the risk justifies it. Place protection before the cutter, not after it, and maintain it (magnet cleaning schedule, sensor checks, and documented reject procedures). Design the system so operators can remove contaminated loads safely: clear access, defined jam-clearing procedures, and lockout/tagout steps for maintenance. Keep spare knife sets or at least a sharpening plan if your supply stream is unpredictable. Granulators typically suffer damage faster from metal, so treat metal control as part of the machine selection rather than an add-on.

Is “shredder + granulator” always better than a single machine?

No. Two stages add footprint, power demand, and additional maintenance points. They make sense when your incoming scrap varies in shape and size, or when you need tighter control of flake geometry for washing and extrusion. A single-stage granulator can be the right choice for consistent, relatively clean rigid parts that feed evenly. A single-shaft shredder alone can also work when your goal is safe breakdown and stable handling rather than final flake sizing. The right answer depends on feed consistency, contamination risk, and downstream quality requirements.

What information most often gets missed when sizing these machines?

Buyers often share polymer type and throughput target, but skip the details that drive real capacity: part geometry, wall thickness range, and contamination risk. A crate and a thick purge block can both be “HDPE,” but they behave very differently at the infeed and at the knives. Photos and a simple part-size range usually improve the accuracy of a recommendation more than more spec-sheet numbers. If you want a stable kg/h number, share the worst-case part and contamination scenario, not only the clean sample.