What Does It Cost to Start a Plastic Recycling Venture?

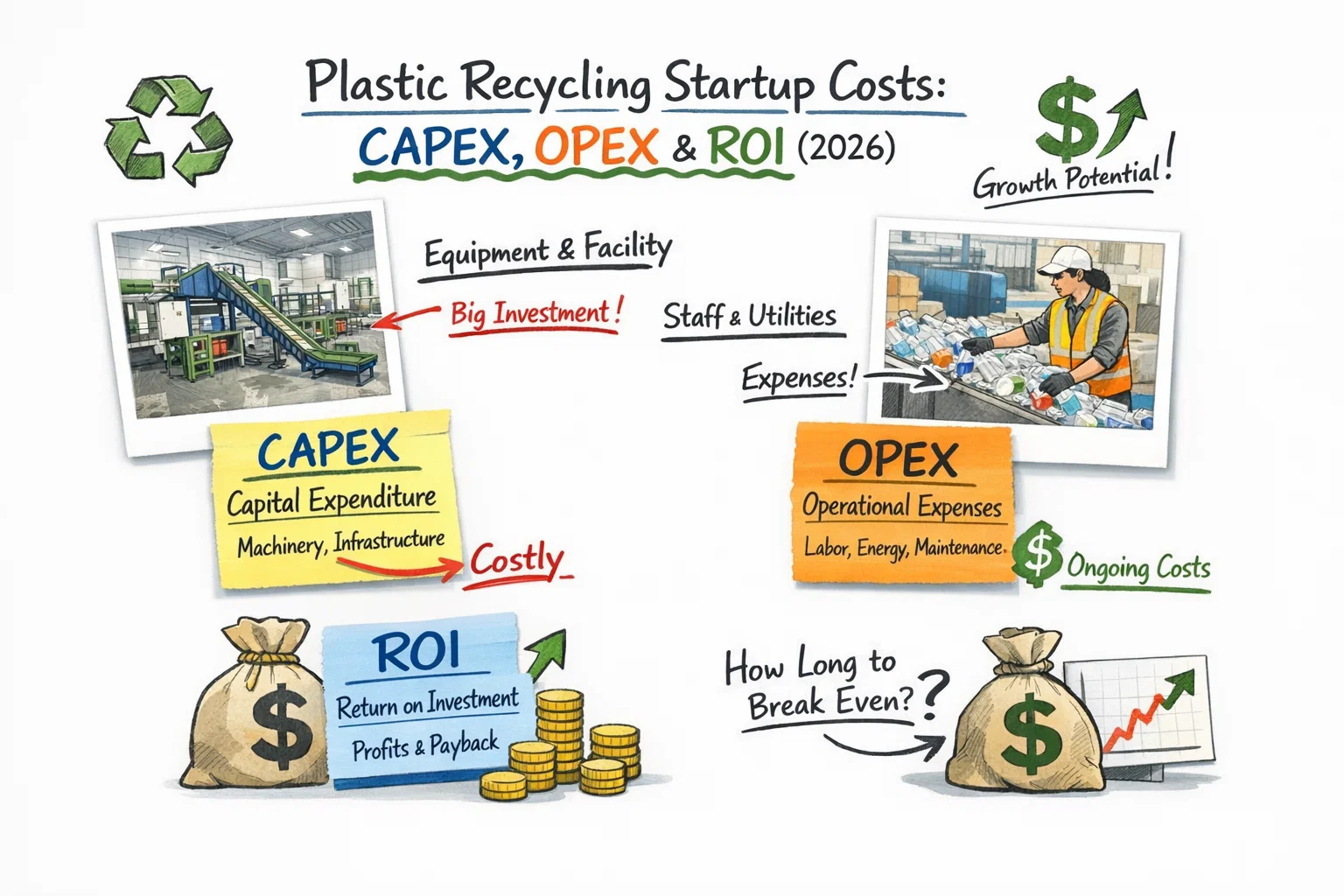

Launching a plastic recycling business is a capital-intensive decision driven by CAPEX, OPEX, and long-term operating efficiency. This guide explains realistic startup costs for a mid-size industrial recycling plant, showing where the money goes and which decisions most directly affect profitability and breakeven time.

Quick Cost Snapshot

The ranges below reflect a mid-size industrial starter plant with shredding, washing, and optional pelletizing. Small pilot projects and large fully automated plants may fall outside these ranges.

Typical investment range

- Total startup investment: $400,000 – $1,300,000+

- Machinery & process equipment: 40–50% of total CAPEX

- Facility & utilities: 20–30% of total CAPEX

- Working capital: at least 3 months recommended

Key profitability levers

- Equipment uptime and reliability

- Pellet or flake quality and consistency

- Energy and water consumption per ton

- Inbound and outbound logistics efficiency

CAPEX Overview

Capital expenditure includes everything required to reach an operational, compliant facility. CAPEX decisions are difficult to reverse and have a long-term impact on operating margins.

Typical CAPEX components

- Recycling machinery and auxiliary equipment

- Building lease retrofit or purchase

- Electrical upgrades and power distribution

- Water handling and drainage systems

- Fire safety and environmental controls

Often overlooked items

- Installation and commissioning

- Spare parts and maintenance tools

- Material conveying systems

- Quality control and testing equipment

- Contingency budget (5–15%)

Machinery & Equipment Costs

Estimated range: $200,000 – $800,000+

Equipment quality is the single most important factor influencing long-term ROI. Low-cost machinery often results in higher energy consumption, frequent downtime, and inconsistent product quality.

High-capacity lines with advanced sorting, hot washing, and melt filtration can exceed this range depending on throughput and automation level.

| Process stage | Typical equipment | Purpose |

|---|---|---|

| Size reduction | Shredders, granulators, metal separation | Prepare material for washing and extrusion |

| Washing & separation | Friction washers, float-sink tanks, hot wash | Remove contaminants and improve purity |

| Drying | Dewatering units, thermal dryers | Stabilize moisture before extrusion |

| Extrusion & pelletizing | Extruders, filters, pelletizers | Produce uniform recycled pellets |

Facility & Infrastructure

Estimated range: $50,000 – $300,000 (lease/retrofit) · $1M+ (purchase)

- Minimum ~10,000 sq ft for standard industrial lines

- Three-phase industrial power and upgraded panels

- Water filtration and wastewater compliance

- Fire protection and safety zoning

Feedstock Procurement

Estimated range: $20,000 – $50,000 (initial inventory)

Baled plastic is not free. Pricing depends on polymer type, contamination, and regional supply. Stable contracts with post-industrial sources reduce volatility and improve margins.

Transportation & Logistics

Estimated range: $5,000 – $25,000 per month

Transport inefficiency can erase profit. Compaction at the source, optimized routing, and balanced storage are critical.

Permits, Compliance & Insurance

Estimated range: $15,000 – $40,000

Recycling facilities are regulated as industrial waste operations. Environmental permits, fire compliance, and specialized insurance are mandatory in most jurisdictions.

Labor & Training

Estimated range: $50,000 – $150,000

Even automated plants require skilled operators and technicians. Budgeting for training and preventive maintenance protects uptime.

OPEX Reality

Typical operating costs

- Electricity and water

- Labor and payroll burden

- Feedstock purchases

- Maintenance and consumables

- Inbound and outbound freight

Margin protection strategies

- Upstream contamination control

- Stable throughput design

- Routine downtime analysis

- Clear buyer specifications

ROI & Breakeven

Well-run industrial recycling plants often target breakeven within 18–24 months when throughput and quality targets are met. Equipment uptime is the most critical performance metric.

Startup Cost Summary

| Cost category | Estimated range (USD) |

|---|---|

| Machinery & equipment | $200,000 – $800,000+ |

| Facility & utilities | $50,000 – $300,000 |

| Feedstock inventory | $20,000 – $50,000 |

| Permits & compliance | $15,000 – $40,000 |

| Logistics & handling | $20,000 – $80,000 |

| Working capital | $100,000 – $200,000 |

| Total investment | $400,000 – $1,300,000+ |

Next Steps

Defining polymer type, contamination level, target output, and capacity is the fastest way to refine your budget and reduce risk.

Explore complete recycling workflows and system options at Energycle Recycling Solutions.

FAQ

Is $300,000 enough to start?

It may work for small or specialized setups, but most industrial plants budget higher to achieve stable throughput and consistent quality.

What is the biggest hidden cost?

Electrical upgrades, water handling, and downtime are the most common surprises. Logistics inefficiency can also quietly erode margins.

Flake or pellets?

Flake requires lower CAPEX and is simpler to run. Pellets are more standardized for buyers but require tighter process control and filtration.