Solutions avancées de convoyeurs à vis pour les industries modernes

Améliorez vos capacités de manutention grâce à nos convoyeurs à vis de précision. Conçus pour une stabilité et une durabilité inégalées, nous proposons des modèles de filtration d'eau simples, doubles, triples et spécialisés, personnalisables selon vos besoins opérationnels précis.

Demander un devisLibérez l'efficacité et la fiabilité

Une polyvalence inégalée

Manipule avec expertise divers matériaux, des poudres fines et des granulés aux substances collantes ou filandreuses, dans une multitude d'applications industrielles.

Efficacité optimisée

Conçu pour le transport continu de matériaux sur des distances variables avec une consommation d'énergie minimale, maximisant ainsi votre rendement opérationnel.

Maintenance réduite

Une construction robuste avec des spirales résistantes à l'usure et moins de pièces mobiles se traduit par des coûts d'entretien réduits et une durée de vie prolongée.

Solutions sur mesure

Conceptions entièrement personnalisables, y compris le diamètre de la vis, le pas et le matériau, pour répondre à des besoins de transport spécifiques et à des contraintes d'espace.

La mécanique du mouvement des matériaux

Au cœur de chaque convoyeur à vis se trouve un système méticuleusement conçu lame à vis hélicoïdale (tarière)Cette tarière tourne à l'intérieur d'une auge ou d'un tube robuste.

La vis sans fin, en rotation, propulse méthodiquement le matériau sur toute la longueur du convoyeur. Cette action facilite flux continu et contrôlé des marchandises du point d'admission au point de déchargement.

Les paramètres de conception de la lame de vis (sa taille, sa forme et son pas) sont calibrés avec précision en fonction des caractéristiques du matériau et des exigences de l'application, garantissant ainsi une efficacité de transport optimale.

Diverses conceptions de convoyeurs pour des besoins spécifiques

Nos convoyeurs à vis sont conçus dans diverses configurations pour répondre à diverses exigences opérationnelles, garantissant des performances optimales quel que soit le défi.

Convoyeurs à vis horizontaux

Idéal pour déplacer efficacement des matériaux en vrac horizontalement ou en légère pente. Le cheval de bataille des applications de transfert standard.

Convoyeurs à vis verticaux

Spécialement conçu pour élever des matériaux des points les plus bas vers les points les plus élevés, parfait pour les installations de traitement à plusieurs niveaux.

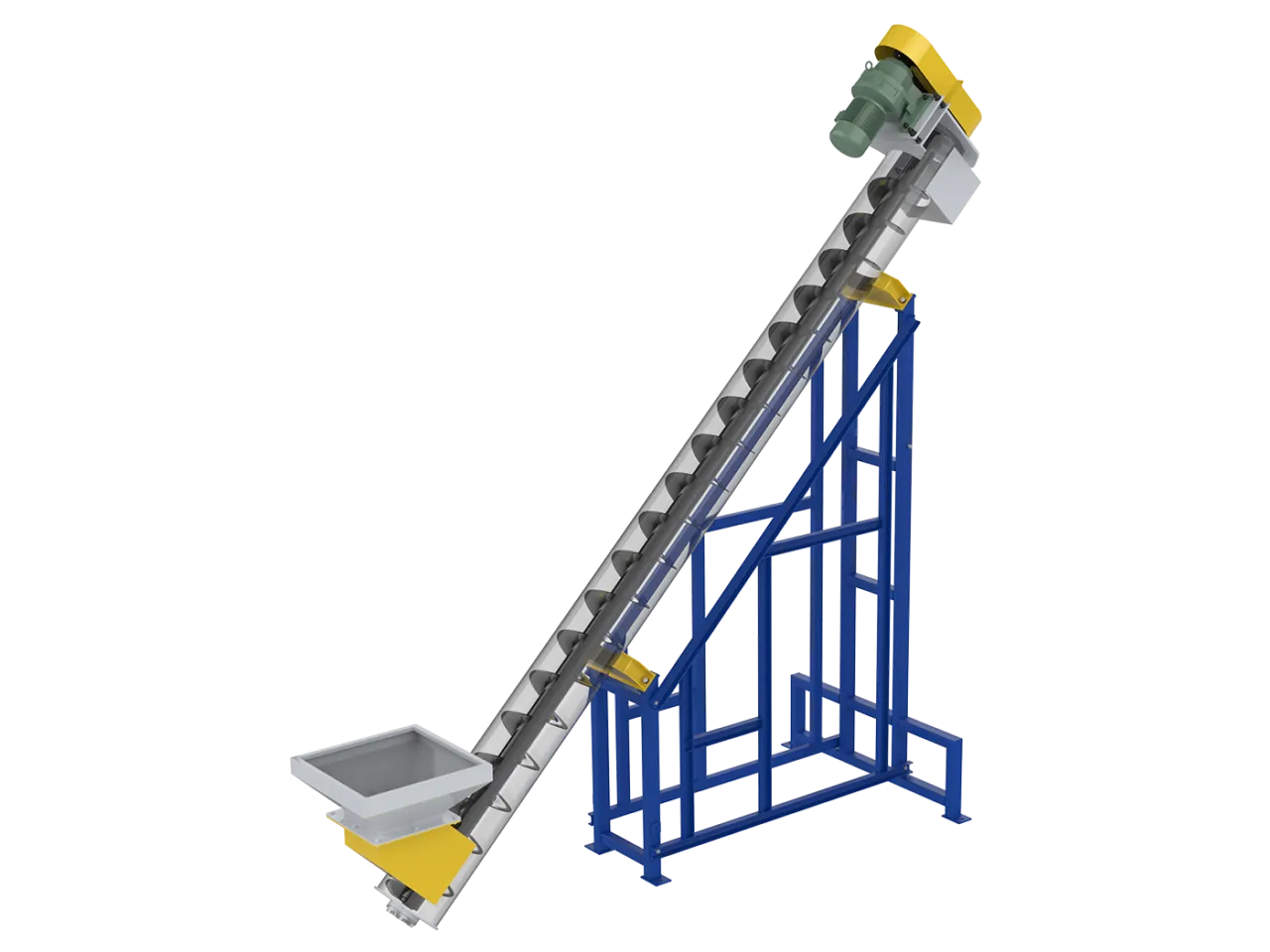

Convoyeurs à vis inclinés

Utilisé pour transporter des matériaux sous un angle, généralement depuis une trémie d'alimentation vers des machines de traitement ou des bacs de stockage.

Convoyeurs à vis sans arbre

La solution optimale pour la manipulation de matériaux difficiles tels que des articles collants, filandreux ou volumineux, évitant l'enchevêtrement courant dans les conceptions à arbre.

Tous les modèles sont dotés de spirales très stables et résistantes à l'usure. Des options de personnalisation du diamètre de la vis (de la plus compacte à la plus grande) et des matériaux de construction sont disponibles pour répondre précisément à vos besoins de transport et à vos contraintes d'espace.

Applications polyvalentes dans tous les secteurs

Les convoyeurs à vis sont indispensables dans un large éventail d'industries, rationalisant les processus critiques et améliorant la productivité.

Agriculture

Céréales, aliments pour animaux, engrais

Alimentation et boissons

Poudres, épices, ingrédients

Traitement chimique

Résines, polymères, additifs

Exploitation minière et minéraux

Minerais, granulats, ciment

Déchets et recyclage

Boues, biomasse, matières recyclables

Les applications courantes comprennent : le transfert de matériaux en vrac (grains, poudres, granulés), les opérations de mélange (par exemple, aliments pour animaux), le dosage précis des ingrédients par lots et les processus de déshydratation des boues et des déchets.

Demander des informations détaillées et des tarifs

Pour recevoir les derniers tarifs, délais et options de configuration personnalisée, veuillez remplir le formulaire ci-dessous. Nos spécialistes vous répondront rapidement.

Informations sur la garantie

Toutes nos machines de recyclage et convoyeurs à vis bénéficient d'une garantie limitée d'un an. Tous nos produits peuvent être personnalisés selon les besoins spécifiques de nos clients.