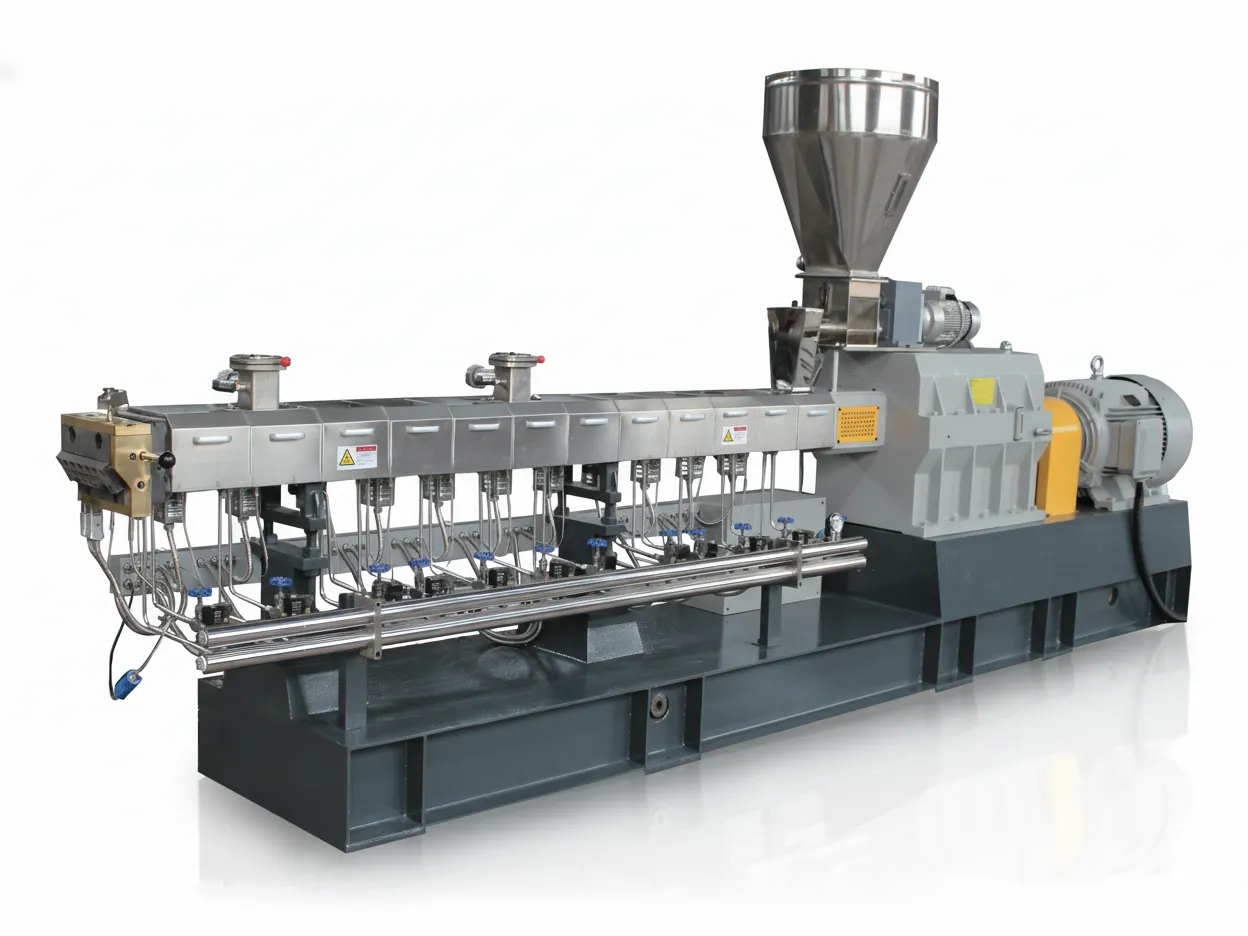

Ligne de compoundage et d'extrusion-granulation à double vis

Conçue spécifiquement pour le mélange, le compoundage, la dévolatilisation et l'extrusion stable, elle est idéale pour les mélanges-maîtres, les composés chargés, les mélanges de polymères et les composés recyclés à haute valeur ajoutée.

Demander un devisConçu pour le compoundage, et pas seulement pour l'extrusion

Contrairement à une extrudeuse à double vis à usage général qui pousse principalement une matière fondue pré-composée, cette ligne est conçue pour disperser uniformément les charges et les additifs, éliminer les composés volatils par ventilation/vide et fournir une qualité de granulés constante grâce à une filtration et une granulation intégrées.

Avantages de la composition à haut rendement

Mélange à haute intensité

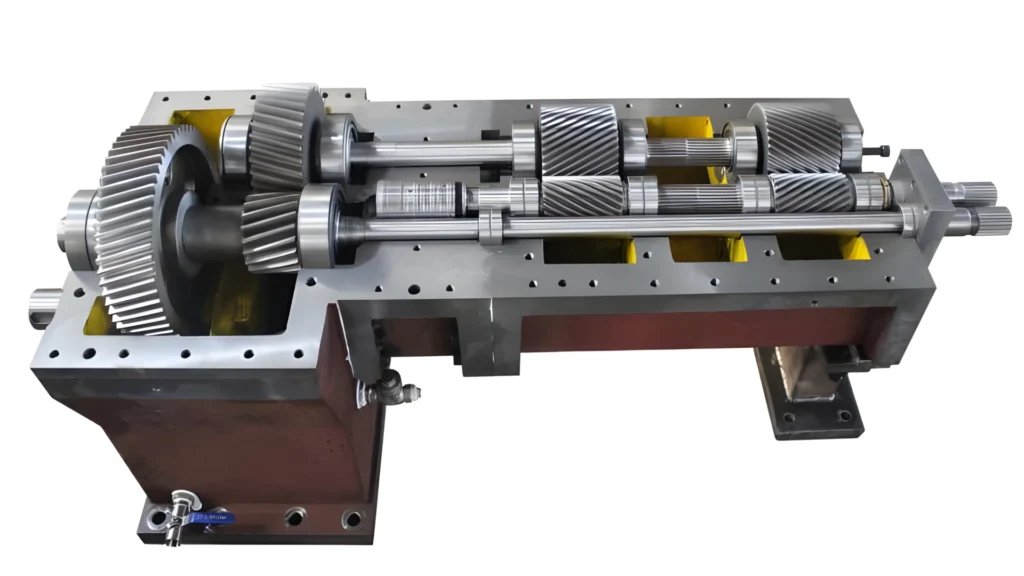

Les éléments de vis optimisés assurent un mélange dispersif et distributif efficace pour des propriétés de composé stables.

Alimentation de précision

Compatible avec les doseurs gravimétriques/volumétriques, l'alimentation latérale et le dosage sur mesure pour les charges, les fibres et les additifs.

Contrôle de la dévolatilisation

Les options de ventilation et d'aspiration éliminent l'humidité et les composés volatils pour des granulés plus propres et moins de défauts.

Filtration et granulation intégrées

Le changeur de tamis hydraulique et les options de granulation (à brins ou à anneaux d'eau) stabilisent la qualité et le rendement.

En quoi diffère-t-il d'une extrudeuse à double vis standard ?

Idéal pour l'extrusion simple

Souvent utilisé pour fondre et transporter des matériaux déjà bien préparés ou pré-mélangés.

- Dispersion limitée à forte concentration de charge/additif

- Moins de zones de préparation dédiées (ventilation, vide, alimentation latérale)

- Les équipements en aval peuvent être externes ou non intégrés.

- Risque accru de variation d'un lot à l'autre pour les recettes complexes

Conçu pour le mélange, le compoundage et l'extrusion

Conçu pour transformer la résine, les charges et les additifs en un composé homogène, puis granulé avec un contrôle qualité stable.

- Modules vis/cylindre configurables pour le mélange dispersif et distributif

- Options d'alimentation pour poudres, fibres, liquides et alimentation latérale

- Ventilation/aspiration pour éliminer les composés volatils et améliorer l'aspect des granulés

- Filtration et granulation intégrées pour des granulés plus propres et uniformes

Flux de travail de mélange, de compoundage et d'extrusion

- Alimentation et dosage : La résine et les additifs sont dosés avec précision (alimentateur principal + alimentateur latéral selon les besoins).

- Mélange intensif : Les éléments à vis dispersent les charges/pigments et répartissent les additifs uniformément dans la matière fondue.

- Ventilation / Vide : L'humidité et les composés volatils sont éliminés pour améliorer la stabilité et réduire les bulles et les odeurs.

- Filtration à l'état fondu : Un changeur de tamis hydraulique capture les contaminants pour obtenir un flux de fusion propre et stable.

- Granulation : Choisissez la granulation par brins ou par anneaux d'eau en fonction du polymère et des exigences en aval.

- Refroidissement et manutention : Les granulés sont refroidis, séchés (si nécessaire) et transportés pour être stockés ou emballés.

Applications de compoundage à haute valeur ajoutée

Production de masterbatch

Mélange-maître à haute concentration de colorant/additif/charge, avec une dispersion homogène et une qualité constante.

Composés chargés et renforcés

Optimisé pour les minéraux (CaCO₃, talc) et le renforcement par fibres avec un débit stable et un contrôle de la fusion.

Composés recyclés

Améliore la consistance des flux recyclés grâce à la dévolatilisation et à la filtration pour des granulés plus propres.

Formulation réactive/fonctionnelle

Permet de créer des zones de mélange contrôlées pour les formulations spéciales et les additifs fonctionnels.

Principaux paramètres techniques

| Ligne | Extrudeuse | Diamètre de la vis (mm) | Vitesse de la vis (rpm) | Puissance du moteur (kW) | Capacité (kg/h) |

|---|---|---|---|---|---|

| GTS52/120 | GTE52 | 51.4 | 600 | 55–75 | 180–260 |

| SJ120 | 120 | 85 | |||

| GTS65/150 | GTE65 | 62.4 | 600 | 90–110 | 260–350 |

| SJ150 | 150 | 85 | |||

| GTS75/180 | GTE75 | 71 | 600 | 132–160 | 450–550 |

| SJ180 | 180 | 85 | |||

| GTS95/200 | GTE95 | 93 | 600 | 185–200 | 650–750 |

| SJ200 | 200 | 85 |

Les spécifications peuvent varier selon la formulation et la configuration. Contactez-nous pour une solution adaptée.

Vitrine de machines

Regardez-le en action

Aperçu rapide du processus de mélange et de granulation.

Garantie et installation

Garantie limitée d'un an

Tous nos systèmes de recyclage et de mélange sont assortis d'une garantie limitée complète d'un an.

Assistance et personnalisation des processus

Nous fournissons des conseils sur la configuration des vis, une assistance à l'installation et un service après-vente adaptés à votre formulation et à vos objectifs de production.

Questions fréquemment posées

Qu'est-ce qui différencie cette ligne de compoundage d'une extrudeuse à double vis classique ?

Ce système est conçu autour des étapes de mélange, de dévolatilisation, de filtration et de granulation, permettant ainsi de transformer de manière fiable la résine et les charges/additifs en un composé homogène. Une extrudeuse standard est généralement dédiée à la simple extrusion de matériaux déjà préparés.

Pouvez-vous prendre en charge les formulations à forte teneur en charges ou en fibres de verre ?

Oui. Avec les doseurs et vis sans fin appropriés, la ligne peut traiter des composés chargés en minéraux et renforcés. La capacité et le taux de chargement maximal dépendent de la formulation, de la granulométrie et de la stabilité du dosage ; partagez votre formulation pour obtenir une configuration recommandée.

Comment choisir entre la granulation par filaments et la granulation par anneau d'eau ?

La granulation par brins est une technique robuste et largement utilisée pour de nombreux composés. La granulation par anneau d'eau est compacte et efficace pour des écoulements de polymère fondu stables. Nous recommandons la méthode en fonction du type de polymère, du débit et des exigences de qualité des granulés.

Fournissez-vous une assistance pour la configuration et la mise en service des vis ?

Oui. Nous pouvons vous recommander des configurations de vis/cylindres et vous fournir des conseils d'installation, une assistance au démarrage et des conseils de maintenance pour vous aider à atteindre rapidement une production stable.

De quelles données avez-vous besoin pour dimensionner correctement la ligne ?

Veuillez nous indiquer le(s) type(s) de polymère(s), les pourcentages de charge/additifs, la capacité cible (kg/h), le niveau d'humidité/de contamination et la méthode de granulation souhaitée. Nous adapterons la taille de l'extrudeuse, les doseurs, le système de filtration et les équipements en aval.

Obtenez un devis pour votre ligne de préparation magistrale

Indiquez-nous votre formulation et la capacité cible : notre équipe vous recommandera les doseurs, la configuration de vis, la filtration et le système de granulation adaptés.