PVC recycling machines transform how manufacturers handle polyvinyl chloride waste in construction and industrial applications. These systems convert discarded PVC profiles—window frames, door systems, and pipe sections—back into usable raw materials, closing the loop on a material that can be reprocessed up to seven times without performance loss.[1]

The Case for PVC Profile Recycling

Construction generates millions of tons of PVC waste annually. When PVC profiles reach end-of-life, recycling offers a practical alternative to landfill disposal or incineration, both of which carry environmental risks due to PVC’s chlorine content.

Mechanical recycling through specialized equipment keeps PVC in productive use. Each ton of recycled PVC saves approximately 50% of the energy required to produce virgin material and reduces air emissions by over 60%.[2] For window profile manufacturing specifically, using 70% recycled content can cut water emissions by more than 60% compared to all-virgin formulations.

PVC’s durability creates a recycling advantage. Individual PVC products last 100 years in typical applications. Multiply that by six or seven recycling cycles, and the material potentially remains useful for 600-700 years.[1]

How PVC Recycling Equipment Processes Profiles

Modern PVC recycling machines handle the complete conversion process, from contaminated profiles to clean granulate ready for manufacturing.

Sorting and Contaminant Removal

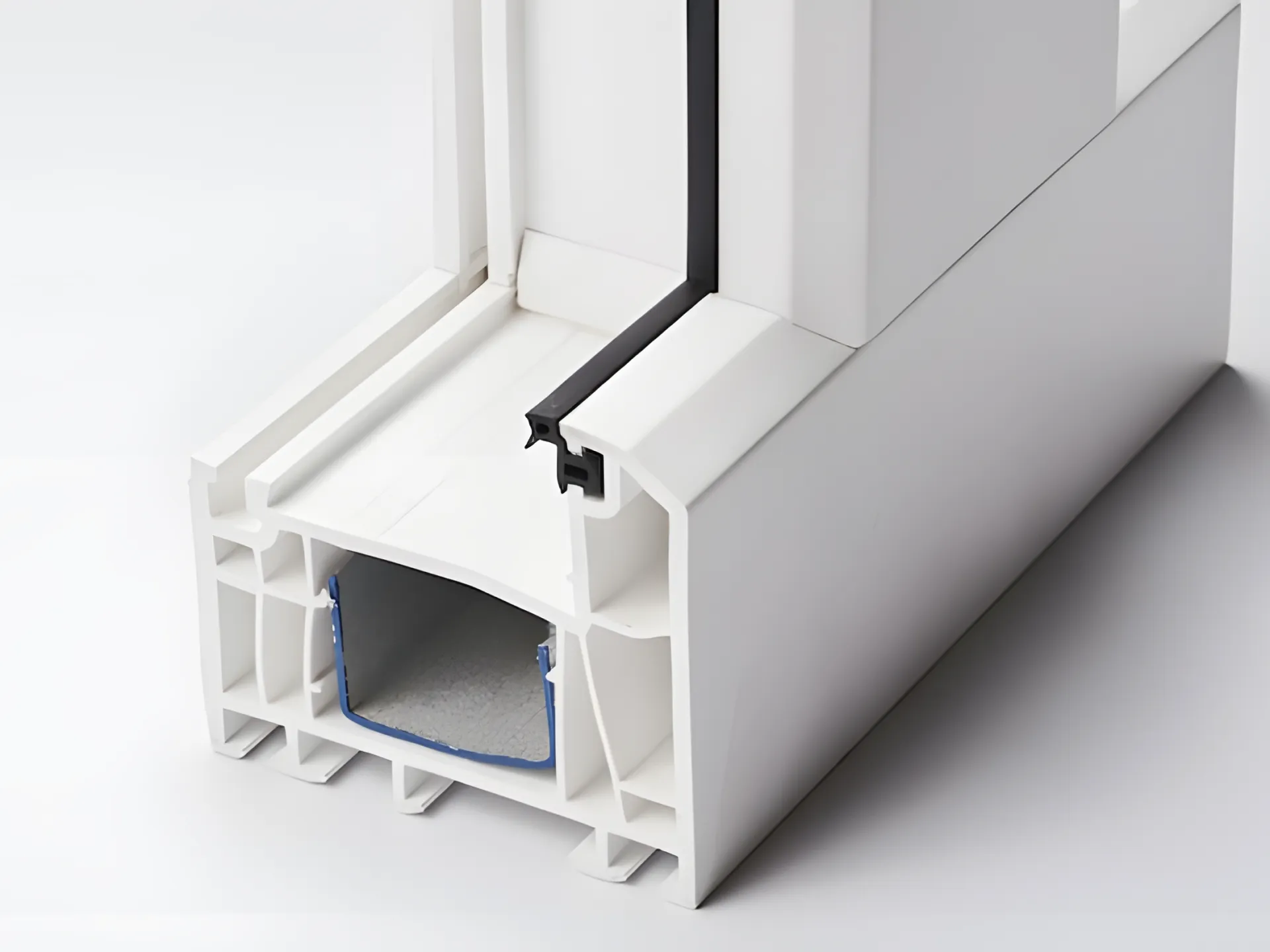

Initial processing begins with inspection and separation. Automated systems remove metal reinforcements, rubber seals, glass fiber inserts, and other non-PVC components. This pre-treatment step determines the quality of the final recycled material—better separation produces cleaner output.

Réduction de taille

Plastic shredders and grinders reduce whole profiles into small flakes, typically 10-20mm in size. This size reduction serves two purposes: it increases surface area for washing and creates uniform feedstock for downstream processing.

Systèmes de lavage

Flakes pass through multi-stage washing to remove surface contamination, adhesives, labels, and residual dirt. Cordes à linge en plastique use friction washers, float-sink tanks, and hot water cycles to achieve cleanliness levels suitable for manufacturing applications. The wash water undergoes treatment and recirculation to minimize water consumption.

Drying and Granulation

Clean flakes move to thermal dryers that reduce moisture content below 0.5%. Dry material then feeds into extruders that melt the PVC and form it into uniform granulate pellets. This granulate serves as direct feedstock for injection molding, extrusion, and other PVC manufacturing processes.

Equipment Capabilities and Throughput

PVC recycling systems scale from small operations processing 100-300 kg/hr to industrial installations handling multiple tons per hour. Throughput depends on profile types, contamination levels, and target granulate specifications.

Advanced machines can process complex profiles that contain multiple materials. Optical sorting technology identifies and separates different PVC formulations by color and composition, maintaining material quality in the recycled output.

Temperature control during melting is critical. PVC degrades if heated excessively, releasing hydrochloric acid that damages equipment and reduces material properties. Modern extruders use precise temperature zones and residence time management to prevent thermal degradation.

Material Quality in Recycled PVC

Properly processed recycled PVC maintains physical properties comparable to virgin material. Tensile strength, impact resistance, and weather durability remain within specification when recycling follows controlled procedures.

The European PVC industry recycled approximately 912,000 tons in 2023, with both post-industrial scrap and post-consumer products contributing to the total.[3] Post-industrial recycling—processing factory off-cuts and production rejects—accounts for roughly 60% of recycled volume because the material is cleaner and more consistent.

Post-consumer recycling presents more challenges. Construction and demolition waste contains mixed materials, weathered surfaces, and variable formulations. Despite these complications, technology improvements continue to increase post-consumer recovery rates.

Addressing Color Variation

PVC profiles come in numerous colors—white, brown, gray, and custom tones. Mixing colors during recycling creates gray or brown granulate that limits application options.

Some processors separate by color to maintain material value. White profiles command higher prices as recycled material because they can be re-pigmented to any color. Dark profiles typically stay dark, suitable for applications where color doesn’t matter or where dark tones are preferred.

Alternatively, manufacturers blend small percentages of off-color recycled material into virgin PVC for non-visible applications, balancing sustainability goals with aesthetic requirements.

Integration with Circular Economy Principles

PVC recycling machines enable closed-loop manufacturing systems. Companies collect their own production scrap plus customer returns, process them on-site, and reintroduce the recycled content into new products.

The VinylPlus program, an industry initiative across Europe, set targets of 900,000 tons recycled annually by 2025, scaling to at least 1,000,000 tons by 2030.[4] Meeting these targets requires both collection infrastructure and processing capacity from recycling equipment.

Chemical recycling represents an emerging alternative approach. Rather than melting PVC mechanically, chemical processes break the polymer into basic building blocks—hydrocarbons, chlorine, and additives—that feed back into industrial production streams.[5] This technology can handle mixed and contaminated streams that mechanical recycling cannot process, though commercial-scale deployment is still developing.

Operating Considerations

Running PVC recycling equipment requires attention to several factors:

Material consistency: Fluctuating input quality affects output specifications. Establish supplier agreements or collection protocols that minimize contamination.

Maintenance schedules: Abrasive fillers in some PVC formulations wear cutting edges and screw flights. Regular inspection prevents unexpected downtime.

Ventilation requirements: Even with proper temperature control, PVC processing releases some volatiles. Adequate exhaust systems protect workers and comply with air quality regulations.

Granulate testing: Periodic sampling verifies that recycled material meets your manufacturing specifications for melt flow, density, and mechanical properties.

Economic and Environmental Returns

Capital costs for PVC recycling lines vary from $100,000 for basic small-scale systems to several million dollars for fully automated industrial installations. Payback periods depend on:

- Volume of available PVC scrap

- Price differential between virgin and recycled material

- Labor costs for sorting and handling

- Energy and water expenses

- Market demand for recycled granulate

Many processors achieve payback in 2-4 years when steady material supply and market demand align. Environmental benefits—reduced landfill tonnage, lower emissions, and decreased virgin material extraction—add value that financial analysis alone doesn’t capture.

Questions fréquemment posées

Can all types of PVC be recycled together?

Rigid and flexible PVC require different processing parameters due to their distinct formulations. Mixing them reduces material quality. Sort by type before processing.

How does recycled PVC compare to virgin material?

When properly processed, recycled PVC performs nearly identically to virgin material in most applications. Some high-stress or critical applications may still specify 100% virgin content.

What happens to PVC that can’t be mechanically recycled?

Heavily contaminated or mixed-material PVC may go to energy recovery (incineration with energy capture), chemical recycling, or, less desirably, landfill. Technology advances continue to reduce the percentage that cannot be mechanically recycled.

Is there a market for recycled PVC?

Yes. Construction profile manufacturers, pipe producers, and other PVC processors actively purchase recycled granulate. Prices typically run 15-30% below virgin PVC, depending on quality and market conditions.

PVC recycling machines provide the mechanical foundation for transforming construction waste into manufacturing feedstock. As collection systems expand and equipment technology advances, recycling rates will continue to grow, keeping more PVC in productive use and reducing the construction industry’s environmental footprint.