Optimiser l'efficacité du recyclage du plastique

Présentation de la machine de déballage verticale : la solution automatisée pour décomposer sans effort les balles de plastique compactées et dynamiser votre ligne de recyclage.

Pourquoi choisir notre déballeuse verticale ?

⚡

Efficacité inégalée

Automatise le processus de déballage, réduisant considérablement le travail manuel et le temps de préparation.

📈

Débit amélioré

Gère plusieurs balles simultanément pour un traitement continu et à volume élevé.

💲

Des économies de coûts importantes

Minimise les dépenses opérationnelles en réduisant les besoins en main-d’œuvre et en rationalisant votre flux de travail.

De la balle à la bouteille en 4 étapes simples

Charger les balles

Utilisez un chariot élévateur pour placer jusqu’à cinq balles sur le convoyeur d’alimentation.

Couper les sangles

Coupez rapidement et en toute sécurité les fils ou les sangles qui maintiennent chaque balle.

Déballage automatisé

Les deux rotors contrarotatifs décomposent les plastiques compactés avec précision.

Sortie continue

Les matériaux détachés s'écoulent vers le convoyeur suivant, prêts à être recyclés.

Conçu pour la performance

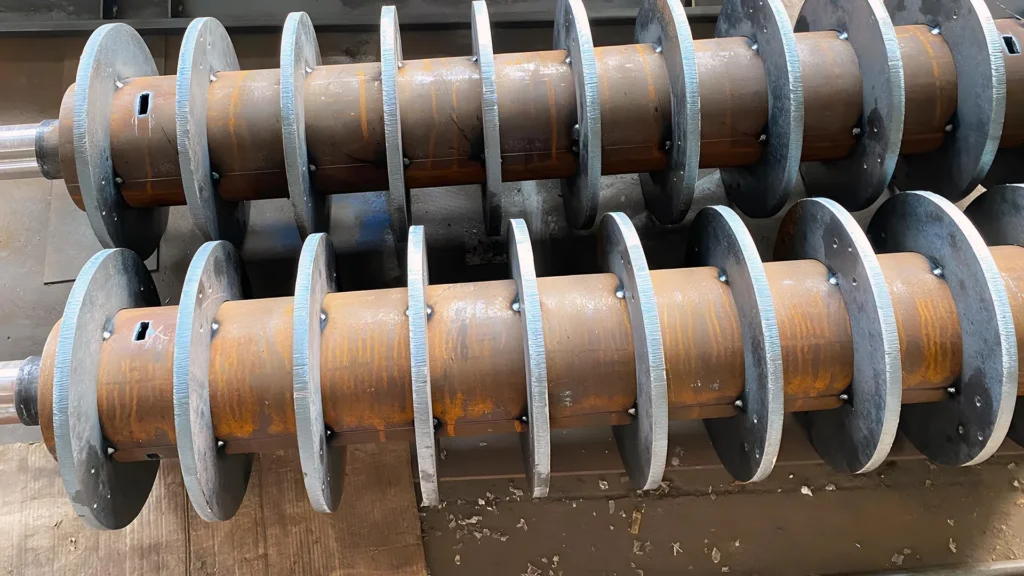

Rotors doubles contrarotatifs

Le cœur de la machine, conçu pour une force de rupture et une efficacité maximales.

Spécifications techniques

| Fonctionnalité | Spécification |

| Puissance du moteur principal | 7,5 kW x 2 (total 15 kW) |

| Dimensions du chargeur | 1550 mm x 1850 mm |

| Matériaux applicables | Bouteilles en PEHD compactées, en PET et autres plastiques rigides |

| Certification | Certifié CE |

| Personnalisation | Des modèles plus puissants et plus grands sont disponibles sur demande |

Applications polyvalentes et sortie de haute qualité

Obtenez une solution et un devis personnalisés

Prêt à révolutionner vos opérations de recyclage ? Remplissez le formulaire ci-dessous et nos experts vous contacteront pour discuter de vos besoins spécifiques.

Questions fréquemment posées

Quelle est la fonction principale de la machine de déballage verticale ?

La fonction principale est de briser automatiquement les balles compactées de plastiques rigides comme les bouteilles en PET et en PEHD, les préparant pour l'étape suivante du processus de recyclage, comme le tri, le lavage ou le déchiquetage.

Cette machine peut-elle gérer des balles de film plastique ?

Non, cette machine est spécialement conçue pour les plastiques rigides. Le film plastique peut s'enrouler autour des rotors et les endommager. Pour les balles de film plastique, nous recommandons un broyeur ou un broyeur de balles spécialisé.

Quelle est la capacité de débit ?

Le débit dépend du modèle et de la densité des balles. Notre modèle standard peut traiter plusieurs tonnes par heure. Nous pouvons vous fournir des chiffres précis en fonction de votre matériau et de la taille de vos balles.

Quelle quantité de travail manuel est nécessaire ?

Le travail manuel est minimal. Un opérateur est nécessaire pour charger les balles avec un chariot élévateur et couper les fils/sangles avant leur entrée dans la machine. Le processus de déballage est entièrement automatisé.