Introduction

Choisir le système de granulation adapté à votre ligne de production de PET est une décision cruciale qui peut avoir un impact significatif sur votre efficacité opérationnelle, la qualité de vos produits et vos coûts à long terme. Parmi les méthodes les plus courantes, on trouve : granulation à anneau d'eau et granulation de brins refroidis à l'eauChaque système a ses avantages et est adapté à différents objectifs de production et contraintes d’installation.

À Machine EnergycleNous aidons les fabricants américains et européens à optimiser leurs lignes de recyclage et de traitement des polymères. Si vous recherchez des systèmes conçus pour les flocons de PET, consultez notre Granulateur à vis unique pour flocons de plastique PET page pour en savoir plus sur les solutions monovis à haut rendement.

Ce guide détaillé vous guidera à travers une comparaison équilibrée des deux technologies de granulation, vous aidant à déterminer la meilleure solution pour vos besoins spécifiques.

Comprendre les bases de la granulation du PET

La granulation du PET (polyéthylène téréphtalate) est un procédé en aval de la chaîne de recyclage du plastique ou de production de polymères vierges, où le PET fondu est transformé en granulés solides. Ces granulés sont plus faciles à manipuler, à transporter et à réutiliser dans les procédés de fabrication.

Les deux systèmes dominants sont :

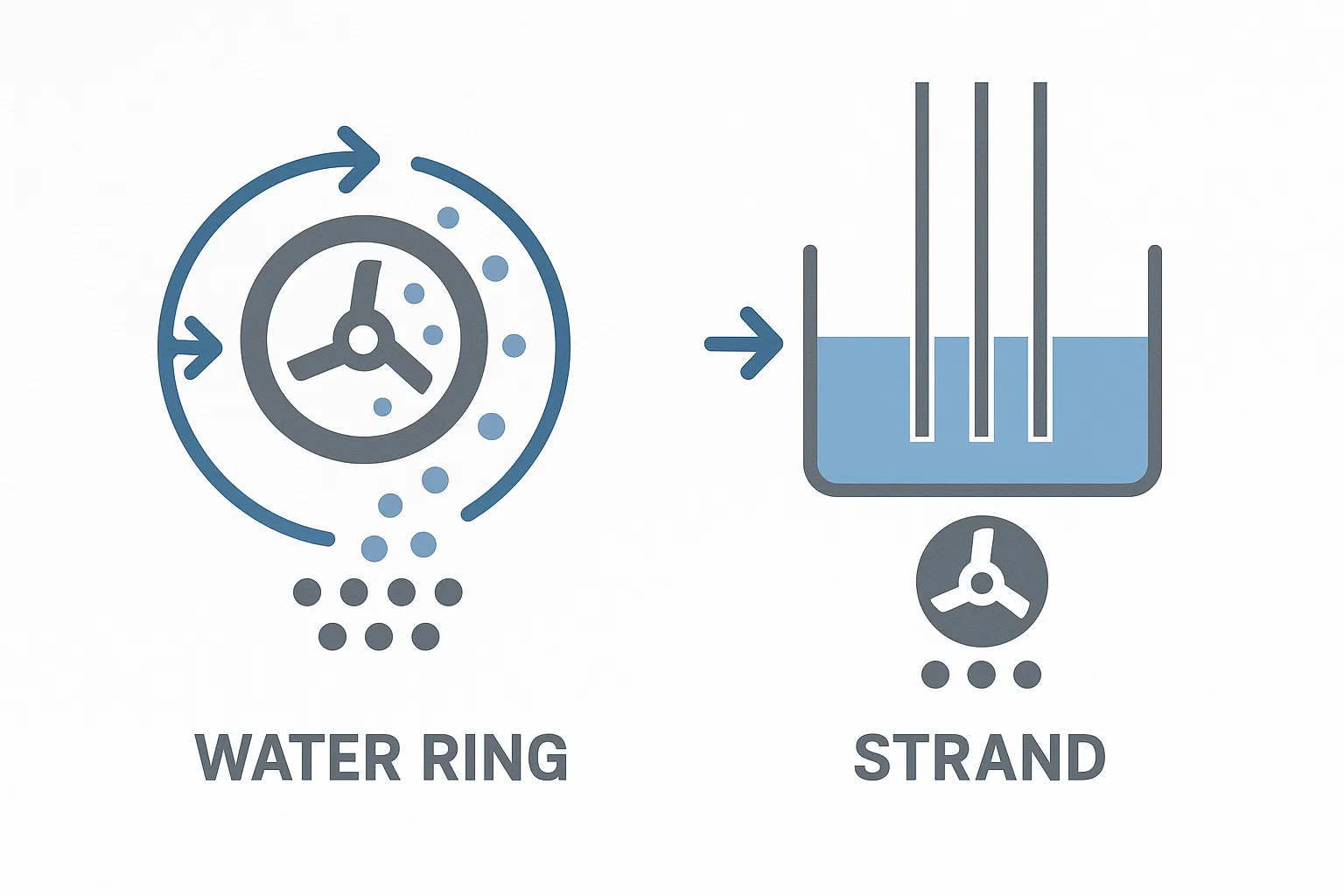

- Granulation par anneau d'eauLe PET fondu est extrudé à travers une filière et découpé immédiatement en granulés par des lames rotatives. Les granulés sont ensuite refroidis dans un anneau d'eau circulant.

- Granulation de brins refroidis à l'eau:Le PET fondu est extrudé sous forme de brins continus, refroidi dans un bain-marie, puis découpé en granulés.

Pour les flocons de bouteilles en PET, Machine Energycle propose également systèmes de granulation spécialisés conçu pour une production stable et une qualité de granulés constante.

Besoins en empreinte et en espace

Granulation par anneau d'eau

Les systèmes à anneau d'eau sont compacts et hautement intégrés. Ils occupent moins d'espace au sol, ce qui les rend idéaux pour les installations où l'espace est limité. Tous les principaux composants, y compris le coupeur, l'anneau d'eau et le sécheur, sont généralement assemblés en une seule unité.

Granulation de brins refroidis à l'eau

Les systèmes à brins nécessitent un espace au sol plus important en raison des bacs à eau de refroidissement et de la disposition des brins. Cette configuration peut poser des limites pour les petites usines ou les installations modernisées. Cependant, elle peut offrir une plus grande flexibilité pour la gestion de matériaux de différentes viscosités.

Machine Energycle recommande d'évaluer l'agencement de votre usine pour comprendre quel système s'adapte le mieux à votre empreinte opérationnelle.

Automatisation et convivialité

Granulation par anneau d'eau

Les systèmes à anneau d'eau sont généralement plus automatisés et nécessitent moins d'intervention de l'opérateur. La pression des lames est souvent auto-ajustable et le séchage des granulés est intégré, ce qui réduit le besoin de manutention.

Granulation de brins refroidis à l'eau

Les systèmes de granulation de brins nécessitent davantage de main-d'œuvre. Les opérateurs doivent garantir un alignement correct des brins et un débit d'eau constant. Le démarrage et l'arrêt requièrent davantage d'attention et de compétences.

Pour les fabricants souhaitant réduire les coûts de main-d'œuvre et améliorer la cohérence, Machine Energycle suggère d'envisager la granulation par anneau d'eau pour ses avantages en matière d'automatisation.

Forme et qualité des granulés

Granulation par anneau d'eau

Produit des granulés ronds et uniformes avec une finition brillante. Ils sont particulièrement adaptés aux applications haut de gamme où l'esthétique et la fluidité des granulés sont primordiales.

Granulation de brins refroidis à l'eau

Les granulés sont généralement cylindriques, avec des extrémités légèrement irrégulières. Bien qu'ils soient toujours fonctionnels pour la plupart des applications en aval, ils peuvent ne pas répondre aux normes d'esthétique ou de traitement haut de gamme.

Si l'uniformité et l'apparence des granulés sont essentielles à votre application, Machine Energycle recommande les systèmes à anneau d'eau.

Tableau comparatif récapitulatif

| Fonctionnalité | Granulation par anneau d'eau | Granulation de brins refroidis à l'eau |

|---|---|---|

| Empreinte | Compact | Un espace plus grand est nécessaire |

| Automation | Haut | Moyen à faible |

| Forme de granulés | Rond, uniforme | Cylindrique, variable |

| Entretien | Modéré | Risque d'usure réduit |

| Coût initial | Plus haut | Inférieur |

| Coût d'exploitation | À long terme plus bas | Coût de la main-d'œuvre plus élevé |

| Débit | Haut | Moyen |

| Flexibilité des matériaux | Moyen | Haut |

FAQ

Q1 : Puis-je installer un granulateur à anneau d'eau sur ma ligne PET existante ?

Oui, beaucoup d'entre eux Machine EnergycleLes modèles sont conçus pour être modernisés, mais les paramètres de disposition et d'extrusion doivent être évalués.

Q2 : Quel granulateur est le plus adapté au PET recyclé ?

La granulation par anneau d'eau est souvent meilleure pour le PET recyclé en raison de son débit plus élevé et de son intégration de séchage supérieure.

Q3 : Existe-t-il des systèmes hybrides disponibles ?

Certains systèmes offrent des options modulaires qui combinent les caractéristiques des deux types de granulation. Machine Energycle peut vous conseiller sur des solutions personnalisées.

Q4 : Quelle est la période de retour sur investissement typique pour la mise à niveau vers un système à anneau d'eau ?

En fonction de votre production et de vos coûts de main-d’œuvre, le délai de récupération peut varier de 1 à 3 ans.

Faites le bon choix pour votre ligne de production

Choisir le bon système de granulation peut façonner l'avenir de votre ligne de production de PET. Machine Energycle vous aider à faire un investissement éclairé et à l’épreuve du temps.

Visitez notre Granulateur à vis unique pour flocons de plastique PET page ou contactez-nous dès aujourd'hui pour discuter de vos besoins.

Demandez un devis personnalisé