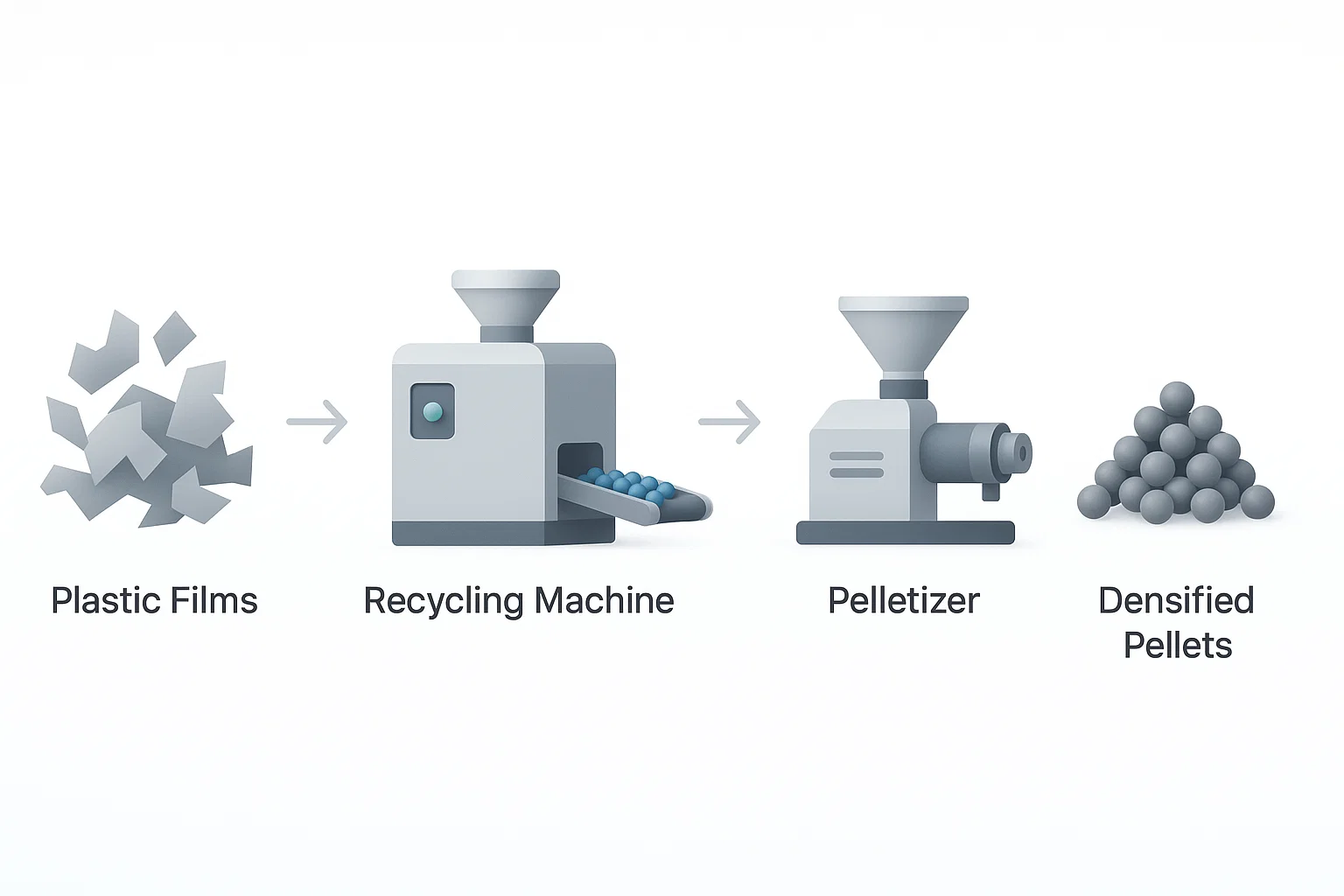

The PP/PE Film Shredding and Densifying Line enhances plastic recycling efficiency through several key functionalities:

- Moisture Reduction:

The line incorporates a screw press squeezer that effectively reduces moisture content in washed plastic films—from approximately 30–40% down to 2–5%. This substantial reduction in moisture significantly lowers the energy demands of subsequent drying stages, which are typically energy-intensive, thereby decreasing operational costs and improving overall process efficiency. - Increased Volume Efficiency and Bulk Density:

By compacting shredded and washed plastic flakes into dense pellets (with a bulk density of approximately 350–410 kg/m³), the system reduces the material’s volume by up to 90%. This densification improves the efficiency of storage, handling, and transportation, resulting in lower logistics costs and smoother downstream processing. - Uniform and Consistent Feedstock:

The densified pellets—typically around 50 mm in length—exhibit uniformity in size and density, which ensures more consistent feeding into extruders and pelletizing systems. This consistency minimizes the risks of bridging and feed interruptions, reduces equipment wear, and ultimately leads to increased throughput and improved quality of recycled outputs. - Enhanced Purity through Contaminant Removal:

Before densification, the system utilizes sink-float separation to remove heavy contaminants, including stones and dirt. In certain configurations, the screw squeezer also removes residual fine particles. These features collectively enhance feedstock purity and contribute to the production of higher-quality recycled pellets. - Improved Downstream Processing:

The resulting semi-dry, densified pellets are ideally suited for both mechanical pelletizing and chemical recycling. Their optimized properties enable faster and more energy-efficient extrusion and molding processes in subsequent recycling phases - Operational Efficiency and Flexibility:

Engineered for ease of operation and maintenance, the line minimizes downtime and enhances productivity. Modular and customizable configurations allow adaptation to specific processing capacities and material requirements, offering added flexibility and scalability to recycling operations.

Conclusion:

The PP/PE Film Shredding and Densifying Line significantly improves the recyclability of plastic films by converting bulky, wet, and contaminated waste into dense, dry, and uniform material. This transformation streamlines feeding into recycling equipment, reduces energy and transportation costs, and enhances the consistency and quality of recycled plastics. As a result, the line supports more sustainable, cost-effective, and high-throughput plastic film recycling operations.