Nel panorama manifatturiero odierno, la spinta verso la sostenibilità e l'efficienza non è mai stata così cruciale. I pellet di plastica riciclata sono in prima linea in questo movimento, offrendo una valida alternativa alle materie prime vergini. Ma non tutti i pellet riciclati sono uguali. La provenienza dei rifiuti plastici, che provengano da una fabbrica o da un contenitore per la raccolta differenziata domestica, fa una differenza significativa.

Questa guida esplorerà i principali vantaggi e limiti dell'utilizzo di pellet di plastica riciclata, concentrandosi sulle due fonti principali:

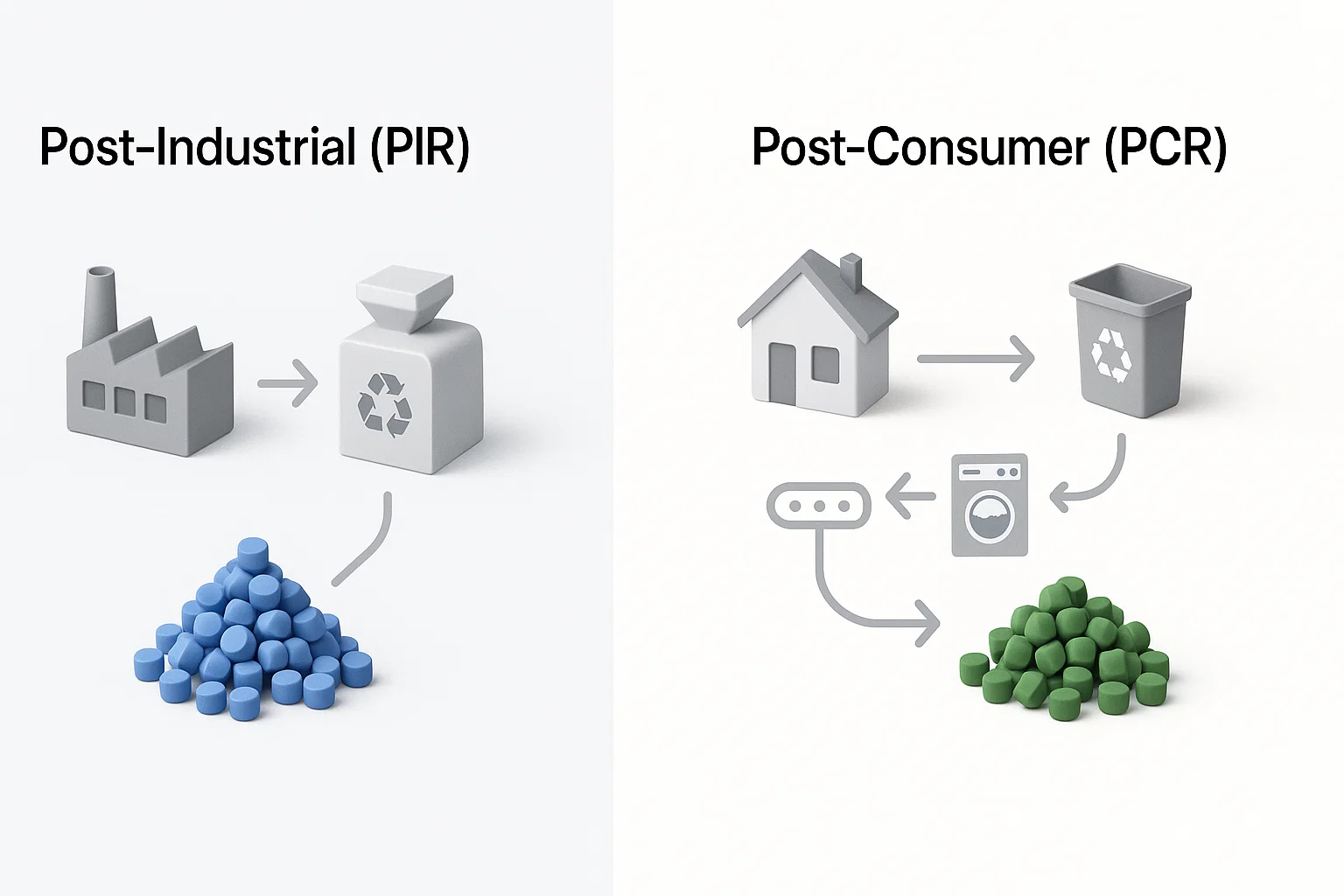

- Resina post-industriale (PIR): Noti anche come rifiuti pre-consumo, si tratta di materiale di scarto pulito recuperato dai processi di produzione interni.

- Resina post-consumo (PCR): Si tratta di plastica recuperata dai flussi di rifiuti domestici o commerciali dopo essere stata utilizzata dal consumatore.

Comprendere questa differenza è fondamentale per effettuare la scelta giusta per la propria linea di produzione.

I vantaggi convincenti dell'utilizzo di pellet riciclati

Optare per pellet riciclati può offrire notevoli vantaggi ai produttori, con un impatto su tutto: dal budget alle credenziali ambientali del marchio.

1. Significativa riduzione dei costi

Questo è spesso il vantaggio più immediato e tangibile. L'approvvigionamento di materie prime vergini rappresenta una spesa operativa significativa. Riciclando internamente i rifiuti, è possibile recuperare e riutilizzare materiale che altrimenti andrebbe perso. I rifiuti post-industriali possono rappresentare 5% o più della produzione di una linea di produzione. Trasformare questi scarti in pellet di alta qualità attraverso un sistema di riciclaggio interno è una decisione finanziariamente oculata che riduce direttamente i costi delle materie prime.

2. Materiale coerente e di alta qualità (soprattutto da PIR)

I pellet generati da fonti post-industriali sono spesso descritti come "quasi come nuovi". Poiché il materiale non è mai stato utilizzato da un consumatore, è privo di contaminanti e le sue proprietà sono note e costanti. La dimensione uniforme e la purezza di questi pellet PIR li rendono ideali per il reinserimento diretto in processi complessi come l'estrusione, garantendo che il prodotto finale soddisfi elevati standard qualitativi.

3. Un'impronta più ecologica

L'utilizzo di pellet di plastica riciclata riduce significativamente l'impatto ambientale. Ogni tonnellata di plastica riciclata utilizzata è una tonnellata di plastica vergine che non necessita di essere prodotta. Questo consente di risparmiare combustibili fossili, ridurre il consumo di energia e diminuire le emissioni di gas serra associate alla produzione di plastica. È un passo chiaro e commerciabile verso un'attività più sostenibile.

4. Integrazione perfetta e versatilità

Uno dei principali vantaggi è la facilità con cui i pellet riciclati possono essere reintrodotti nella linea di produzione. Sono una materia prima versatile, adatta a un'ampia gamma di applicazioni, tra cui:

- Estrusione di film soffiato (ad esempio per imballaggi industriali)

- Estrusione di tubi (ad esempio per drenaggio o condotte)

- Prodotti di produzione come sacchi per rifiuti e tubi in LDPE

In alcuni casi, soprattutto quando si utilizza PIR di alta qualità, il processo è semplice come reimmettere i pellet riciclati nell'estrusore.

Affrontare le sfide: limiti da considerare

Sebbene i vantaggi siano evidenti, è importante essere consapevoli dei potenziali limiti, in particolare quando si lavora con materiali post-consumo.

1. Variabilità nella qualità post-consumo (PCR)

A differenza della natura pulita e uniforme del PIR, i rifiuti post-consumo presentano maggiori sfide. I pellet derivati da fonti PCR possono presentare una maggiore variabilità qualitativa. Ciò è dovuto a diversi fattori:

- Contaminazione: Residui di alimenti, bevande, etichette di carta e adesivi.

- Materiali misti: Una singola balla di rifiuti può contenere diversi tipi di plastica che necessitano di un'attenta selezione.

- Degradazione: La plastica potrebbe essere stata esposta alla luce solare (degradazione UV) o ad altri elementi che ne indeboliscono la struttura.

Per creare pellet PCR utilizzabili sono essenziali un lavaggio, una selezione e una lavorazione accurati, il che aggiunge complessità al processo di riciclaggio.

2. Potenziale di riduzione delle proprietà meccaniche

Il processo di fusione e riformazione può talvolta accorciare le catene polimeriche della plastica, il che può portare a una leggera riduzione delle proprietà meccaniche (come la resistenza alla trazione o all'impatto) rispetto al suo equivalente vergine. Questo è un aspetto ancora più rilevante per i materiali PCR che potrebbero aver già subito molteplici sollecitazioni.

Tuttavia, questo inconveniente può spesso essere mitigato. La qualità dei pellet PCR può essere notevolmente migliorata incorporando masterbatch e additivi che ne migliorano le prestazioni direttamente durante il processo di riciclo e pellettizzazione. Inoltre, per molte applicazioni, una leggera riduzione delle proprietà meccaniche è perfettamente accettabile. In alcuni prodotti, come i sacchi per rifiuti, è persino possibile utilizzare materiale riciclato 100% proveniente da fonti post-consumo.

PIR vs. PCR: un rapido confronto

| Caratteristica | Resina post-industriale (PIR) | Resina post-consumo (PCR) |

| Fonte | Scarti di produzione interna | Rifiuti domestici e commerciali |

| Qualità | Alto, costante, “come nuovo” | Variabile, dipende dall'ordinamento |

| Contaminazione | Da molto basso a nullo | Elevato potenziale di contaminazione |

| Costo di elaborazione | Inferiore | Più alto (a causa della pulizia/smistamento) |

| Il migliore per | Prodotti di alta qualità, reintegrazione diretta | Prodotti in cui il contenuto riciclato 100% è un obiettivo e una leggera variabilità è accettabile |

Conclusione: una scelta intelligente e sostenibile

I pellet di plastica riciclata offrono una valida alternativa per una produzione più economica ed ecologica. Mentre i pellet provenienti da fonti post-industriali offrono un percorso semplice per ottenere materiale di alta qualità a basso costo, le sfide del riciclo post-consumo vengono superate grazie a tecnologie avanzate di selezione e lavorazione.

Comprendendo le caratteristiche distintive di PIR e PCR, i produttori possono prendere decisioni strategiche, selezionando il materiale giusto per la giusta applicazione. Il risultato è un ciclo di produzione semplificato, un budget più sostenibile e un contributo tangibile all'economia circolare.