Wraz ze wzrostem globalnego popytu na tworzywa sztuczne pochodzące z recyklingu, efektywne technologie przetwarzania stają się kluczowe. Mokry plastik granulator Maszyny stanowią serce nowoczesnych linii recyklingowych, ponieważ mogą rozdrabniać, kruszyć i myć zanieczyszczone odpady plastikowe w jednym, usprawnionym kroku. Niniejszy przewodnik wyjaśnia, jak działa granulacja na mokro, podkreśla jej zalety w porównaniu z przetwarzaniem na sucho i przedstawia kluczowe cechy naszych systemów granulacji na mokro.

Dlaczego warto używać granulatora do mokrego plastiku?

Konwencjonalna granulacja na sucho rozkłada odpady z tworzyw sztucznych, ale nie usuwa zanieczyszczeń powierzchniowych, takich jak etykiety, brud i pozostałości. Granulatory na mokro integrują wodę z komorą tnącą, umożliwiając maszynie:

-

Rozbija odpady plastikowe na mniejsze płatki, jednocześnie spłukując brud i etykiety

-

Minimalizacja wytwarzania pyłu i poprawa jakości powietrza w dół strumienia

-

Zmniejsza tarcie i gromadzenie się ciepła, chroniąc materiał przed degradacją termiczną

-

Dostarczaj czystsze, gotowe do mycia płatki, aby zwiększyć efektywność recyklingu

Dzięki takiemu połączeniu granulacja na mokro idealnie nadaje się do przetwarzania tworzyw sztucznych pochodzących od konsumentów, takich jak butelki, folie i sztywne pojemniki.

Jak działają maszyny do granulowania mokrego plastiku?

Granulatory na mokro łączą w sobie mocny wirnik i nieruchome łopatki z ciągłym strumieniem wody. Podczas pracy:

-

Karmienie i wstępne zmniejszanie rozmiaruZanieczyszczone tworzywa sztuczne dostają się do leja i są wychwytywane przez wirnik.

-

Cięcie i mycie z dużą prędkościąWirnik obraca się z dużą prędkością, tnąc materiał za pomocą nieruchomych ostrzy. Woda przepływa przez komorę tnącą, wypłukując zanieczyszczenia.

-

Mokry zrzut:Oczyszczone płatki są odprowadzane za pomocą ślimaka lub przenośnika taśmowego na mokro w celu dalszego mycia lub suszenia.

-

Recyrkulacja wody:Wodę procesową można filtrować i ponownie wprowadzać do obiegu, aby zmniejszyć jej zużycie.

Odpowiednio zaprojektowane granulatory na mokro zapewniają ciągłą wydajność przy minimalnej liczbie zatorów i mniejszym zużyciu.

Kluczowe cechy, na które należy zwrócić uwagę przy wyborze systemów granulatorów do mokrego plastiku

Granulatory mokrego plastiku należy oceniać pod kątem trwałości, zużycia energii i dostępu do konserwacji. Kluczowe cechy konstrukcyjne zazwyczaj obejmują:

-

Stabilność wirnika przy dużej prędkości: Wyważony wirnik zapewnia równomierne cięcie i zmniejsza zużycie spowodowane wibracjami.

-

Efektywny zrzut mokry: Ślimak lub przenośnik wyładowczy, który szybko usuwa łuski, jednocześnie odprowadzając wolną wodę, pomaga ustabilizować dalszy proces.

-

Wystarczający silnik i rezerwa momentu obrotowego: Wystarczająca moc zapobiega spadkowi prędkości przy przerabianiu twardszych tworzyw sztucznych i poprawia stabilność przepustowości.

-

Ochrona przed zużyciem w strefach mokrych: Materiały i uszczelnienia zaprojektowane z myślą o ciągłym narażeniu na działanie wody ograniczają korozję i przedwczesne uszkodzenia łożysk.

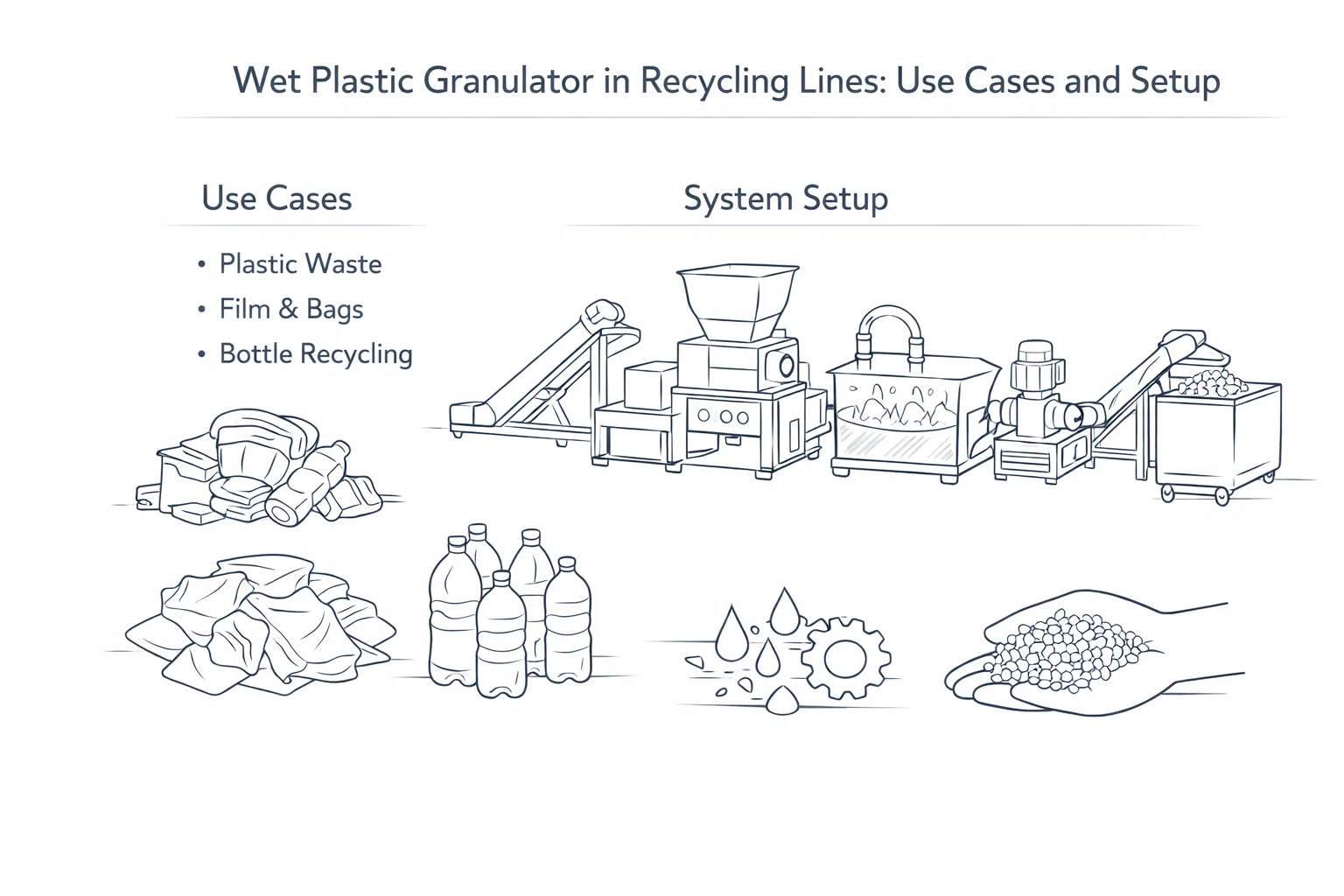

Zastosowania i kompatybilne materiały

Granulatory na mokro są wszechstronne i mogą przetwarzać szeroką gamę odpadów z tworzyw sztucznych, w tym:

-

Butelki i pojemniki HDPE

-

Skrzynki i nakrętki PP

-

Folia LDPE/LLDPE i folia rolnicza

-

Butelki PET (wstępne mycie)

-

Mieszane sztywne tworzywa sztuczne z etykietami lub brudem

Dzięki wykorzystaniu wody w procesie cięcia maszyny te zapewniają czystsze płatki, co zmniejsza obciążenie kolejnych etapów mycia i oddzielania.

Wskazówki dotyczące konserwacji zapewniające niezawodną pracę

Aby zapewnić sprawną pracę granulatora mokrego plastiku, należy stosować się do poniższych wskazówek:

-

Kontrola wirnika i noży: Regularnie sprawdzaj ostrość i rozstaw ostrzy; w razie potrzeby wymień je lub wyreguluj.

-

Konserwacja systemu wodnego:Wyczyść filtry i dysze natryskowe, aby utrzymać stały przepływ i ciśnienie.

-

Smarowanie łożysk:Aby zapobiec przedwczesnemu zużyciu, należy przestrzegać zalecanego harmonogramu smarowania.

-

Czyszczenie ekranu:Upewnij się, że sita wyładowcze nie są zatkane, aby zapobiec przegrzaniu i spadkowi wydajności.

-

Sprawdź sprzęgło i silnik:Sprawdź wyrównanie sprzęgła i temperaturę silnika, aby zapobiec uszkodzeniom.

Właściwa konserwacja wydłuża żywotność maszyny, ogranicza przestoje i zapewnia stałą jakość wyników.

Kryteria wyboru dostawcy granulatorów do mokrego plastiku

Wybierając dostawcę, należy priorytetowo traktować niezawodność operacyjną i wsparcie cyklu życia:

-

Dopasowanie konfiguracji: Możliwość dopasowania konfiguracji noży, typu wyładowania i przepustowości do materiału i układu.

-

Udokumentowane odniesienia: Dowody na istnienie podobnych instalacji i warunków wsadu.

-

Gotowość części zamiennych: Przejrzyste terminy realizacji i lista zalecanych części zamiennych (noże, sita, łożyska, uszczelnienia).

-

Odpowiedź serwisu: Wsparcie przy uruchomieniu, proces rozwiązywania problemów i wskazówki dotyczące konserwacji.

-

Przejrzystość handlowa: Przejrzysty zakres, założenia dotyczące mediów (recyrkulacja wody) i oczekiwania dotyczące wydajności.

Lista kontrolna konfiguracji: Integracja granulatora mokrego plastiku z linią recyklingu

Skorzystaj z tej listy kontrolnej, aby uniknąć wąskich gardeł i niepotrzebnego zużycia podczas uruchamiania granulatora na mokro:

-

Umieszczenie w linii: Zazwyczaj po sortowaniu ręcznym i przed rozdzieleniem materiału pływającego od opadu lub myciem ciernym granulator wykonuje wstępną redukcję rozmiaru i płukanie powierzchni.

-

Rozpylanie wody i recyrkulacja: Zapewnij stabilne pokrycie natryskiem komory tnącej; przed recyrkulacją zamontuj filtrację (sito/osadnik), aby zapobiec ścieraniu się noża i przyspieszeniu zużycia go przez cząstki stałe.

-

Obsługa wypisu: Sprawdź, czy będziesz używać ślimaka lub przenośnika do odprowadzania mokrych płatków i dopasuj urządzenia znajdujące się dalej w strumieniu (płuczkę cierną, odwadniacz lub suszarkę wirową) do natężenia przepływu mokrych płatków.

-

Dopasowanie docelowego rozmiaru: Wybierz sito/perforację na podstawie późniejszego płukania i specyfikacji płatków kupującego; zbyt drobne sortowanie zwiększa ilość drobnych cząstek i obciążenie oczyszczalni wody.

-

Kontrola stanu noży i szczelin: Przed zwiększeniem przepustowości ustal rutynową kontrolę ostrości ostrza i odstępu między nożami.

-

Test uruchomieniowy: Przeprowadź krótki test z najgorszym możliwym surowcem (etykiety, brud, zmienność wilgotności) i sprawdź strumienie odrzutów oraz przejrzystość wody, aby zatwierdzić ustawienia.

Chcesz dowiedzieć się więcej?

Jeśli planujesz modernizację linii recyklingowej lub rozpoczęcie nowego projektu, zrozumienie roli granulacji na mokro jest niezbędne. Aby uzyskać szczegółowe specyfikacje i ceny, zobacz szczegóły dotyczące naszego granulatora do mokrego plastiku tutaj. Nasz zespół chętnie doradzi Państwu w wyborze odpowiedniej konfiguracji, która spełni Państwa oczekiwania.

Odniesienia

- Energycle — Granulator do mokrego plastiku

- Energycle — Rozwiązania w zakresie recyklingu

- Energycle — Skontaktuj się z nami

- OSHA — Przegląd zabezpieczeń maszyn

- OSHA — Kontrola niebezpiecznej energii (blokada/etykietowanie), 29 CFR 1910.147

- ISO — Wytyczne dotyczące recyklingu tworzyw sztucznych (przegląd normy ISO 15270)