Plastic Recycling Machines & Turnkey Lines

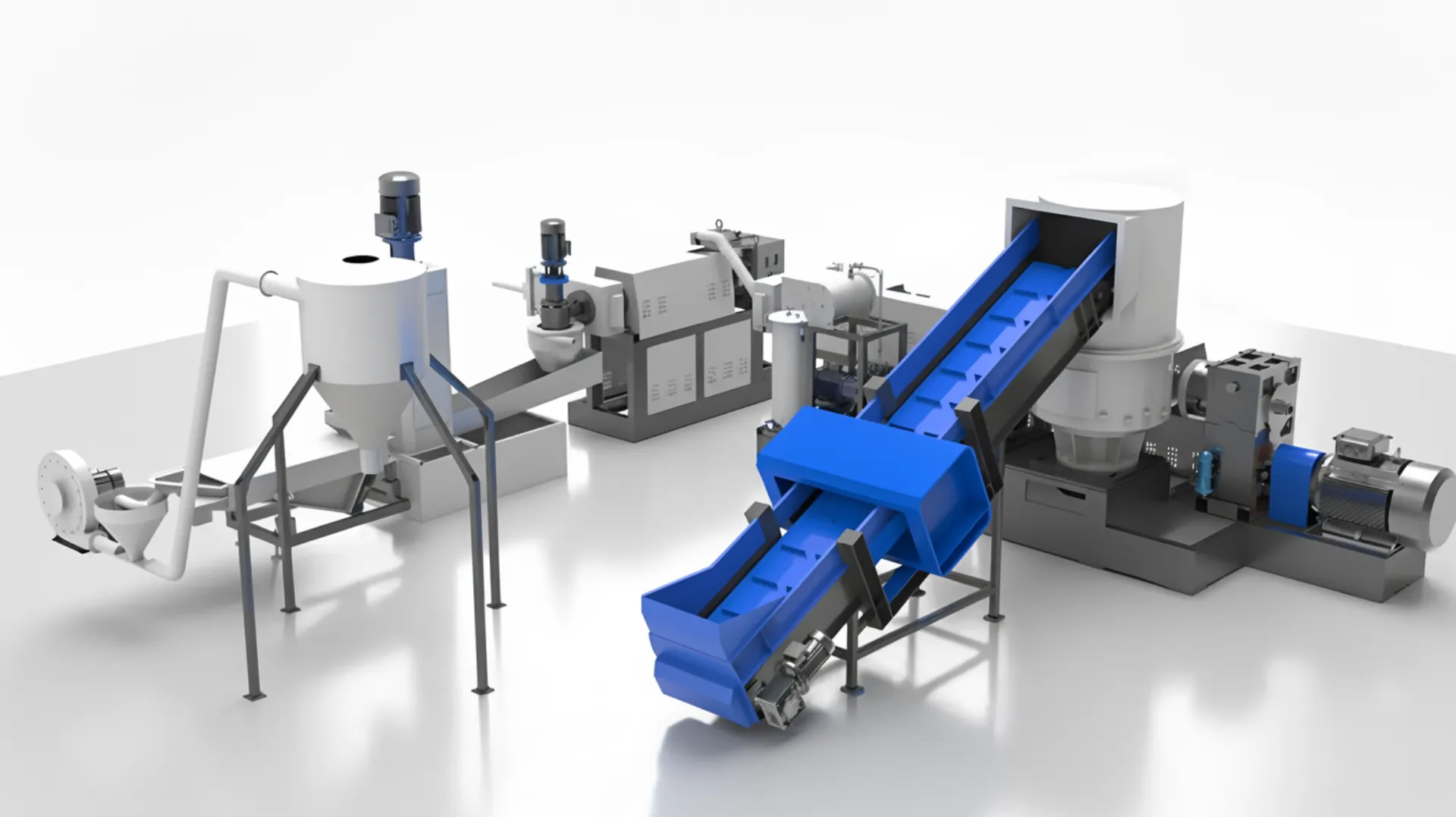

Turn PET, HDPE, PP and PE film into high‑quality, market‑ready pellets with synchronized washing, drying, filtration and pelletizing — engineered for stable throughput and consistent quality.

About Energycle & Editorial Review

What We Do

Energycle designs and manufactures plastic recycling equipment and turnkey lines spanning sorting, size reduction, washing, drying and pelletizing. Every configuration is tailored to your materials, cleanliness and capacity targets.

Quality & Compliance

Built under an ISO 9001 quality system with CE‑compliant machines. Safety, energy efficiency and maintainability are designed into each module.

How to Engage

Share your feedstock and goals and our engineers will recommend a matched lineup and line layout. For site visits or references, contact us: Contact Sales.

What Is a Plastic Recycling Machine?

An integrated, modular system that converts sorted plastic waste into clean flakes or pellets through staged size‑reduction, washing, drying and pelletizing.

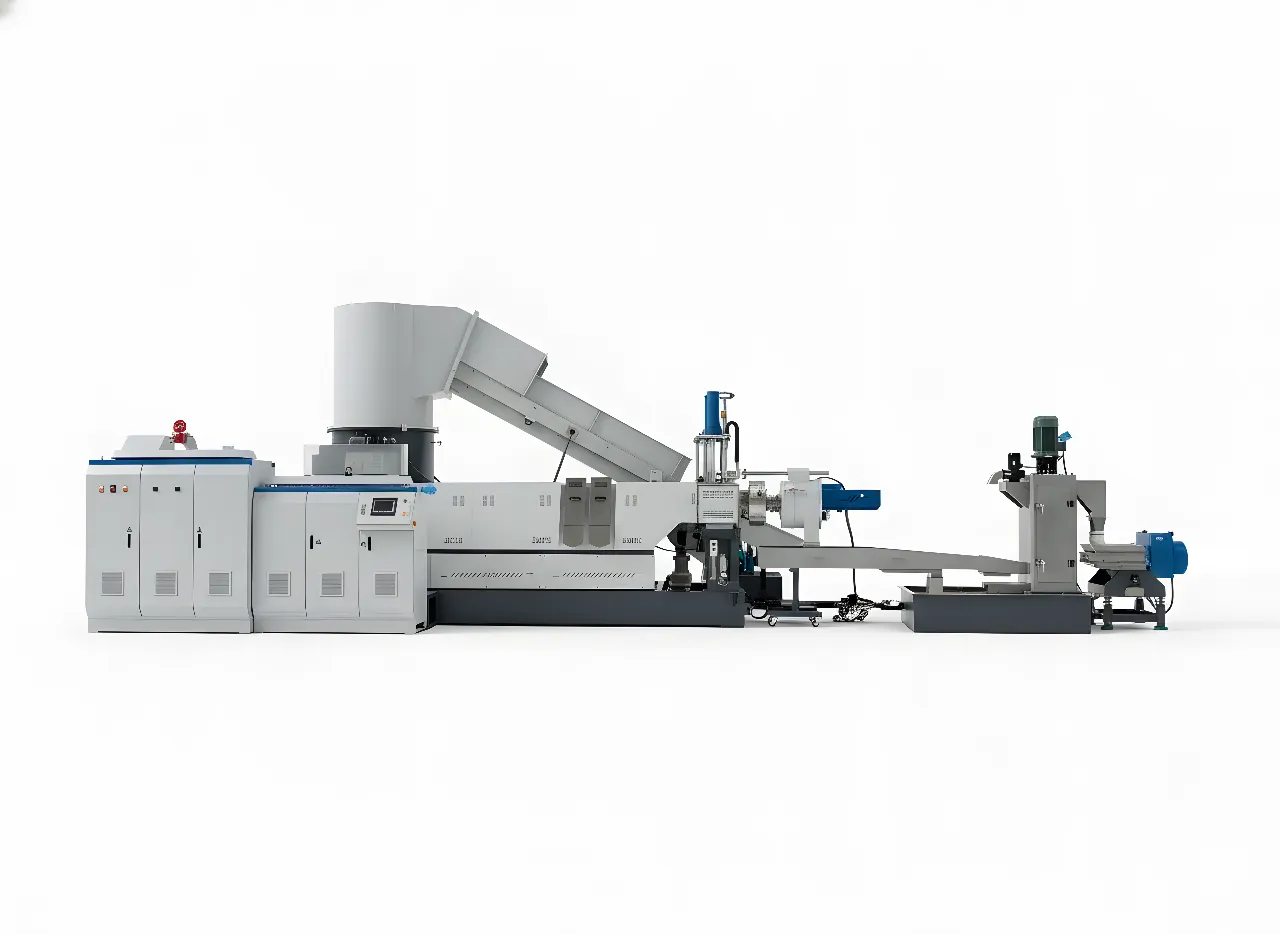

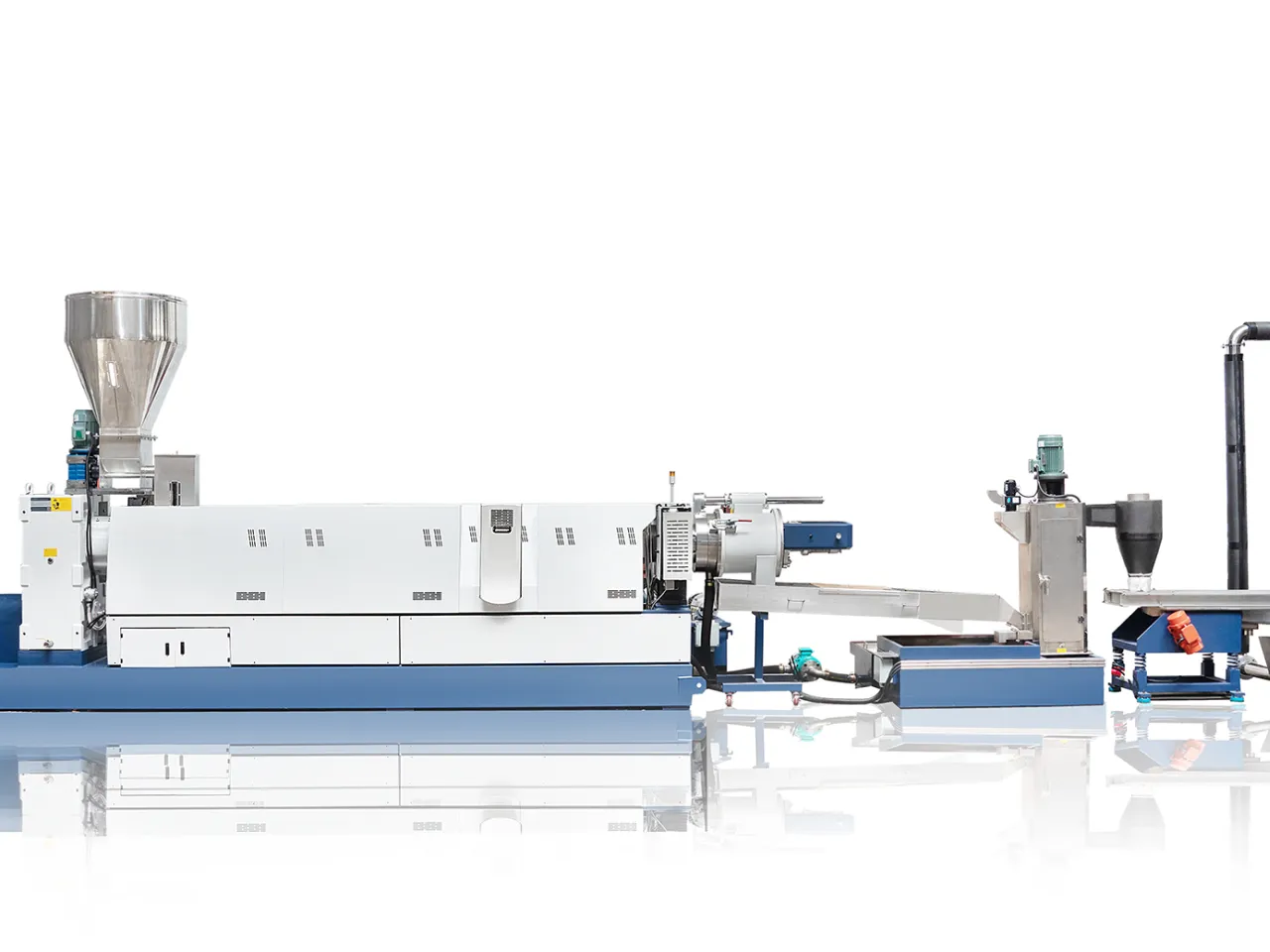

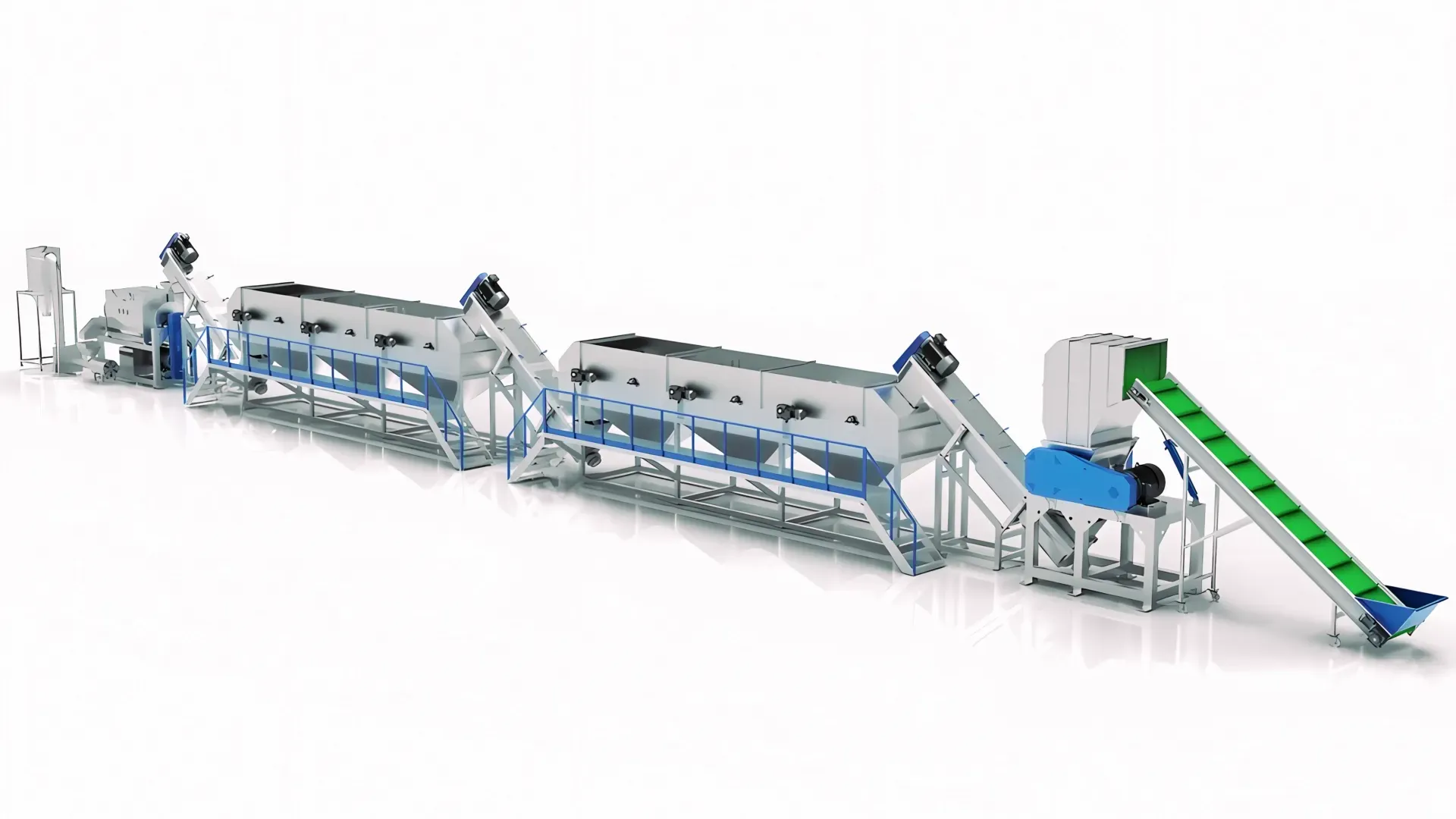

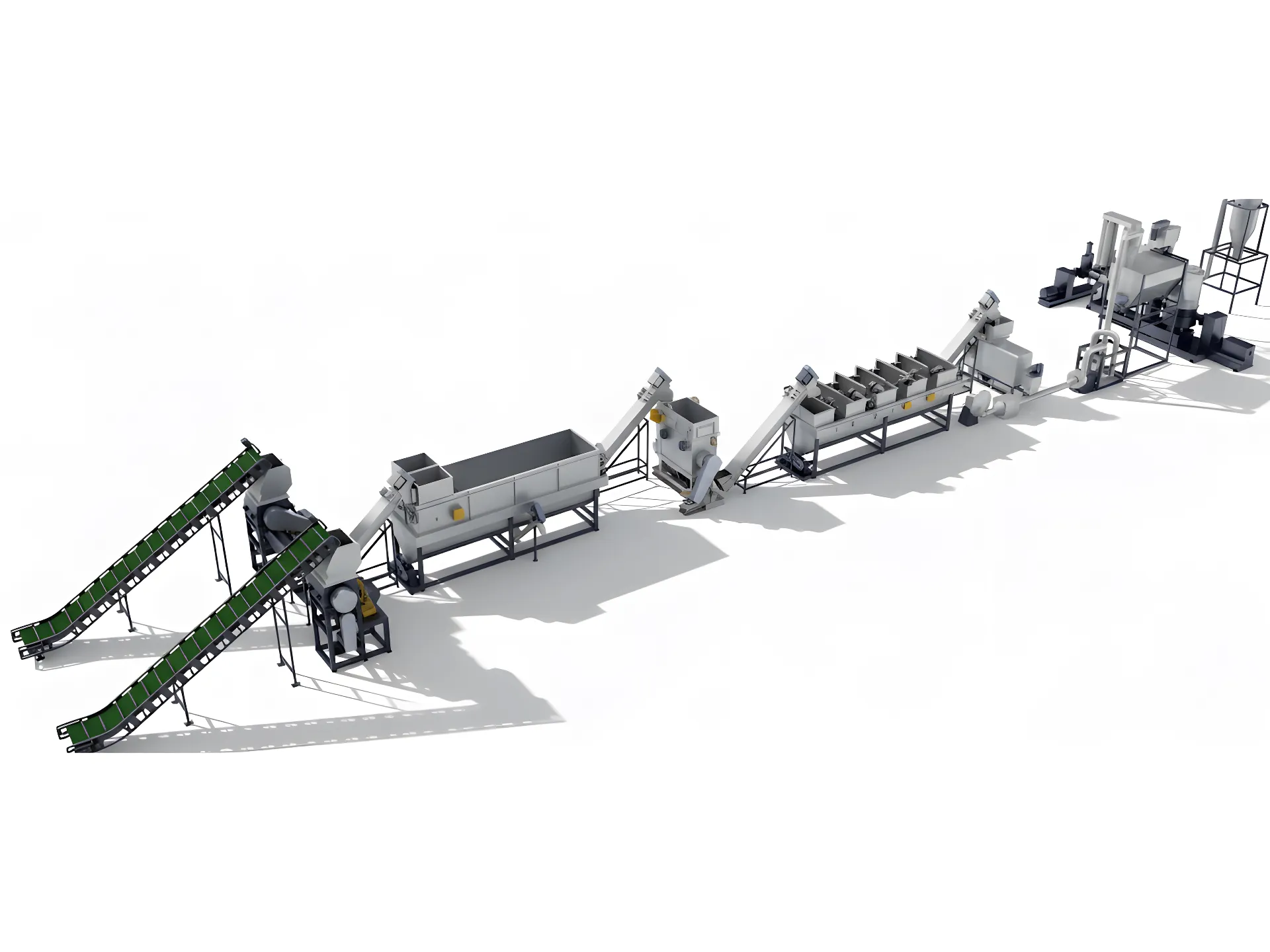

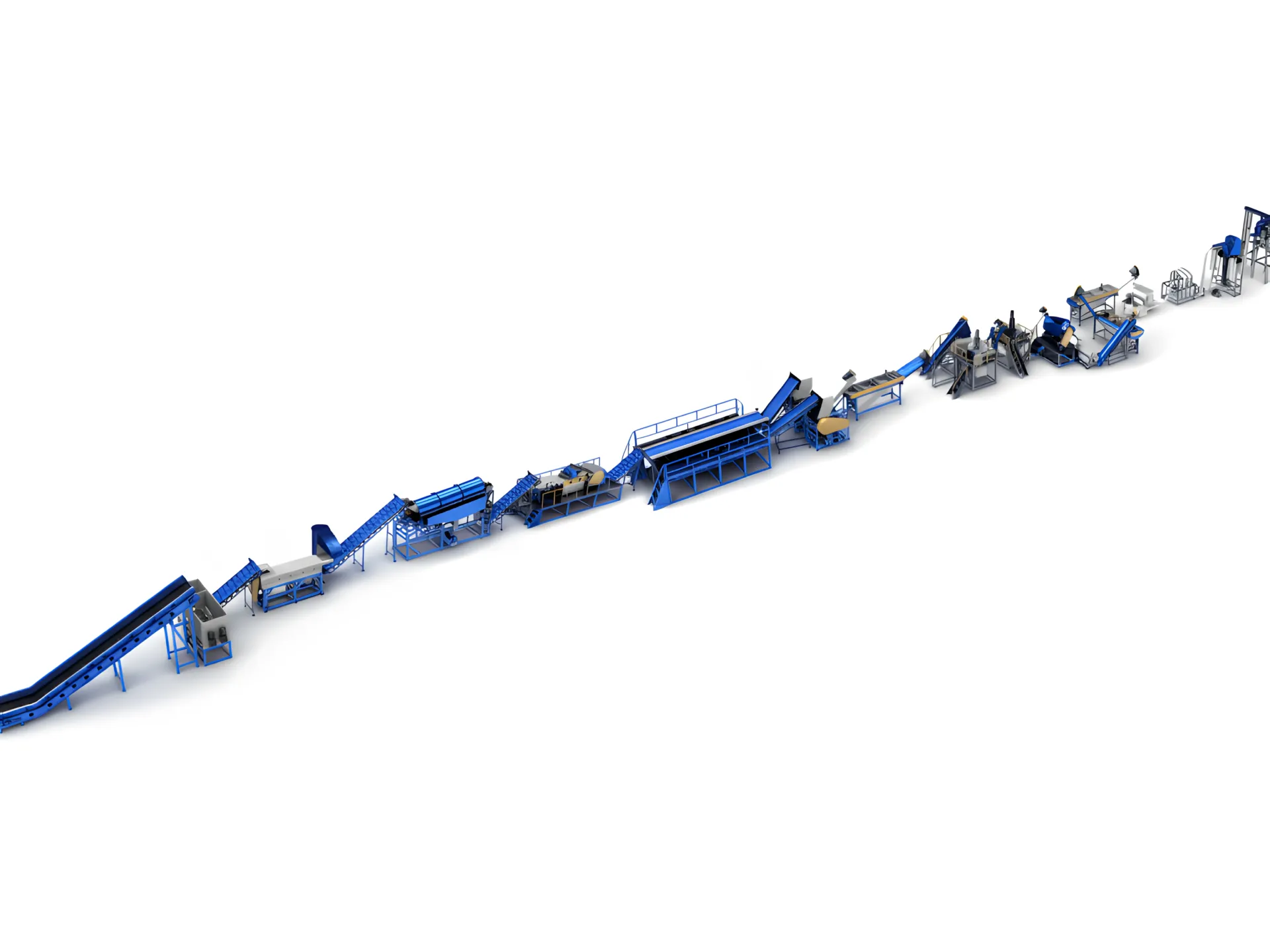

A plastic recycling machine (often configured as a full line) combines multiple modules to process post‑consumer or post‑industrial plastics. Typical lines include automated conveying, shredding or granulation, intensive washing with separation, dewatering and thermal drying, and finally extrusion with filtration, degassing and pellet cutting. The result is high‑purity flakes or uniform pellets that are ready for reuse in manufacturing.

Our systems are designed to be modular and scalable, so you can start with essentials and expand capacity or capabilities as your material mix and market evolve.

Core Modules

- Sorting & pre‑classification

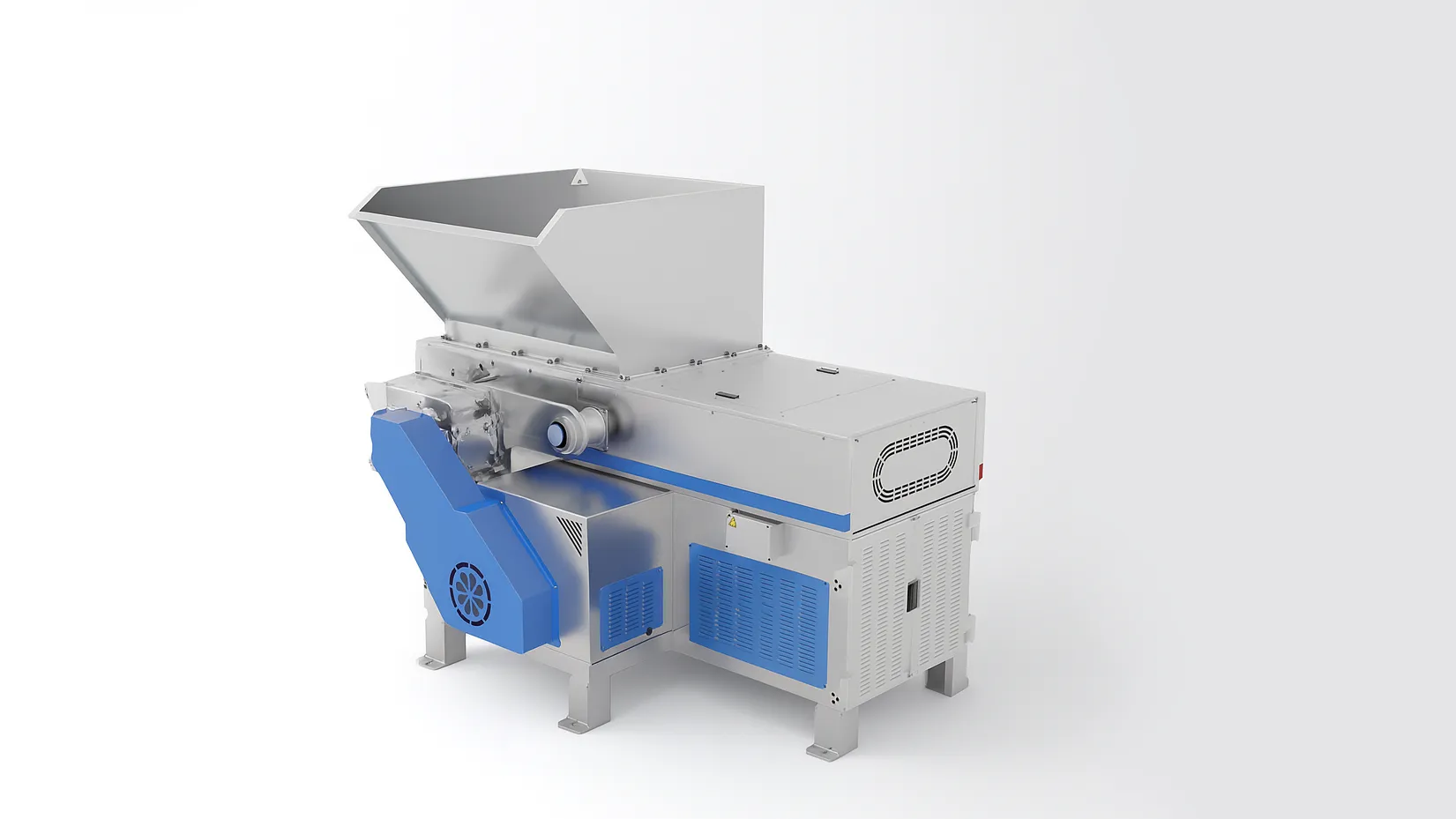

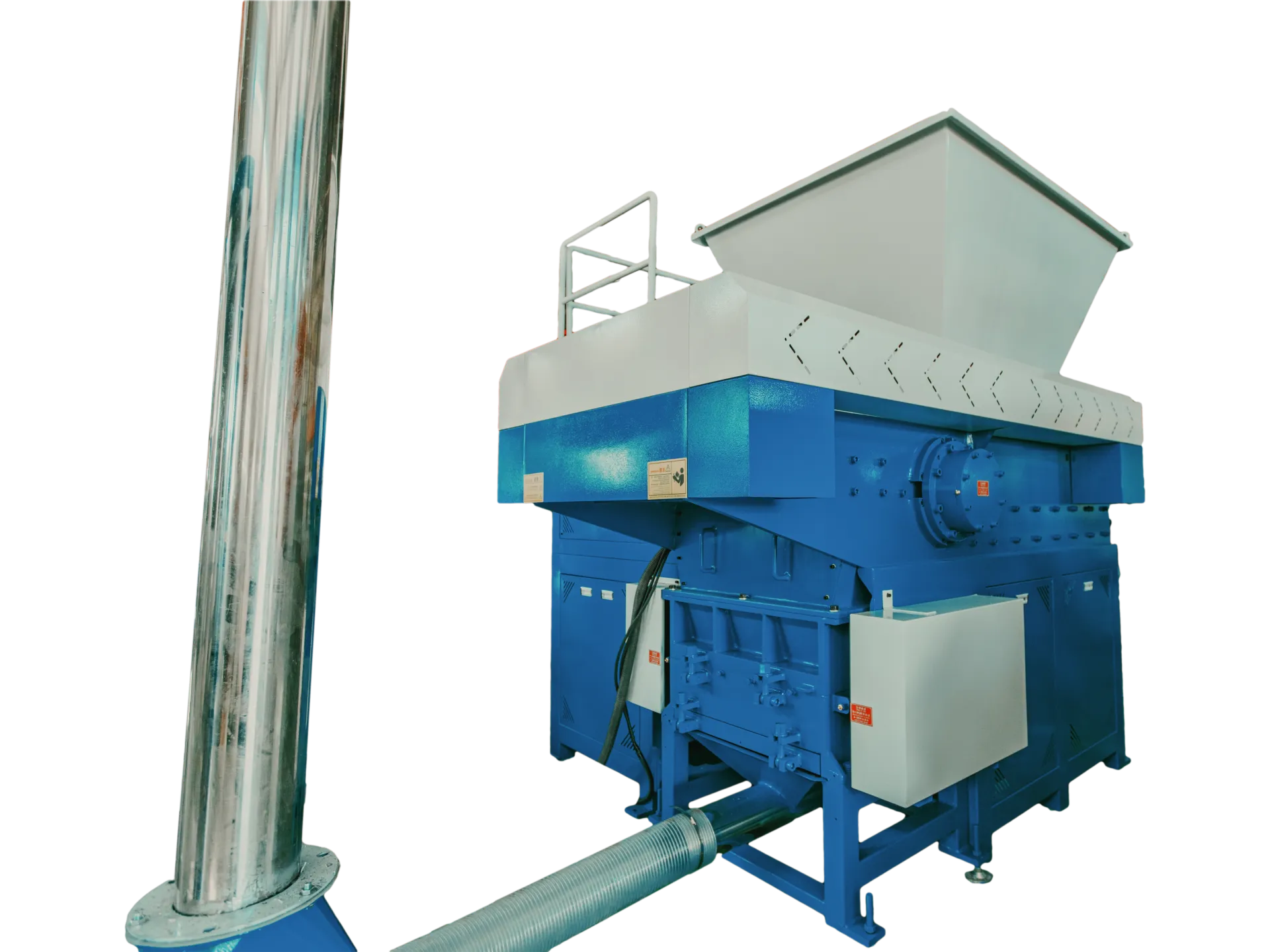

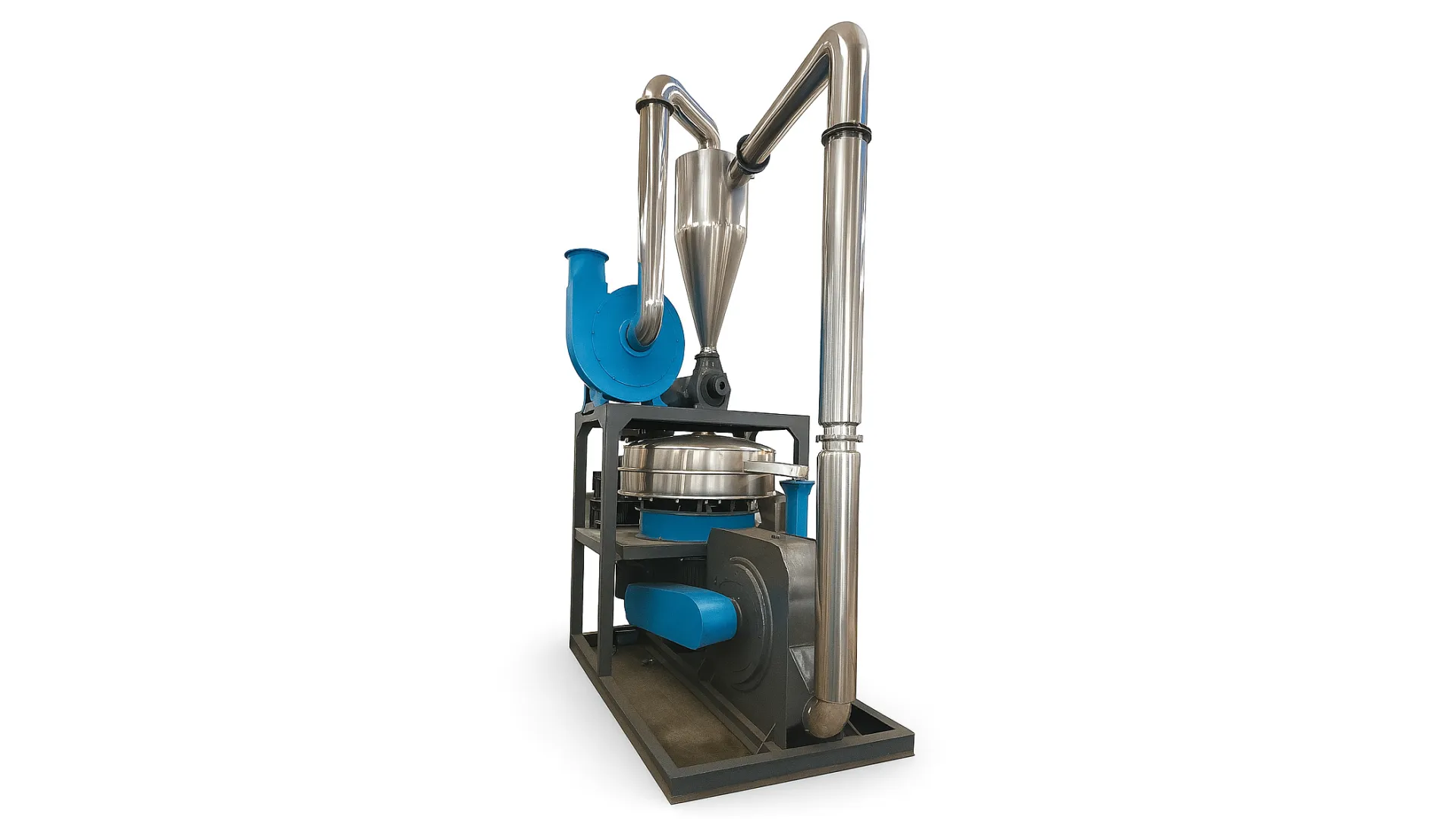

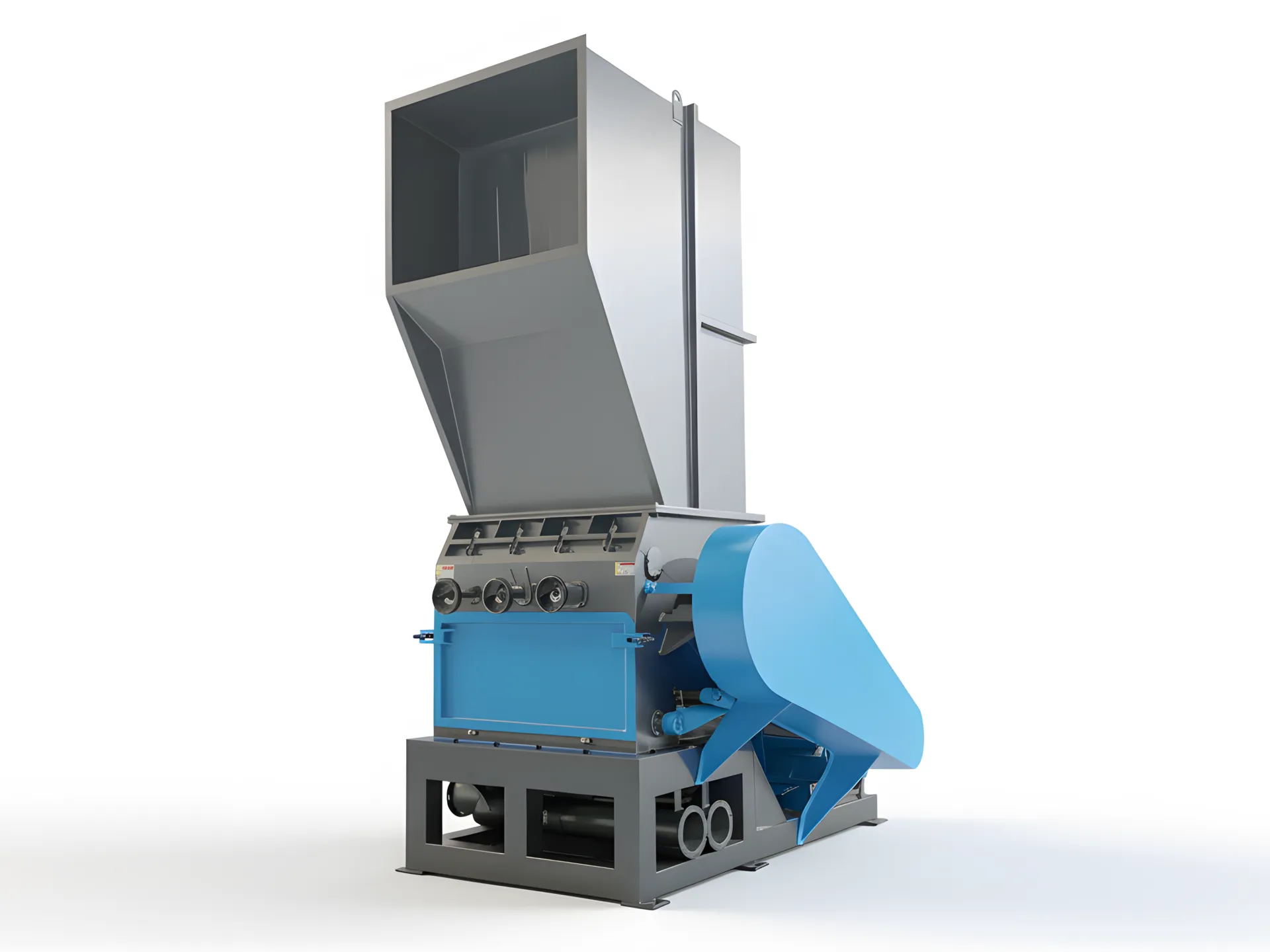

- Size reduction (shredder/granulator)

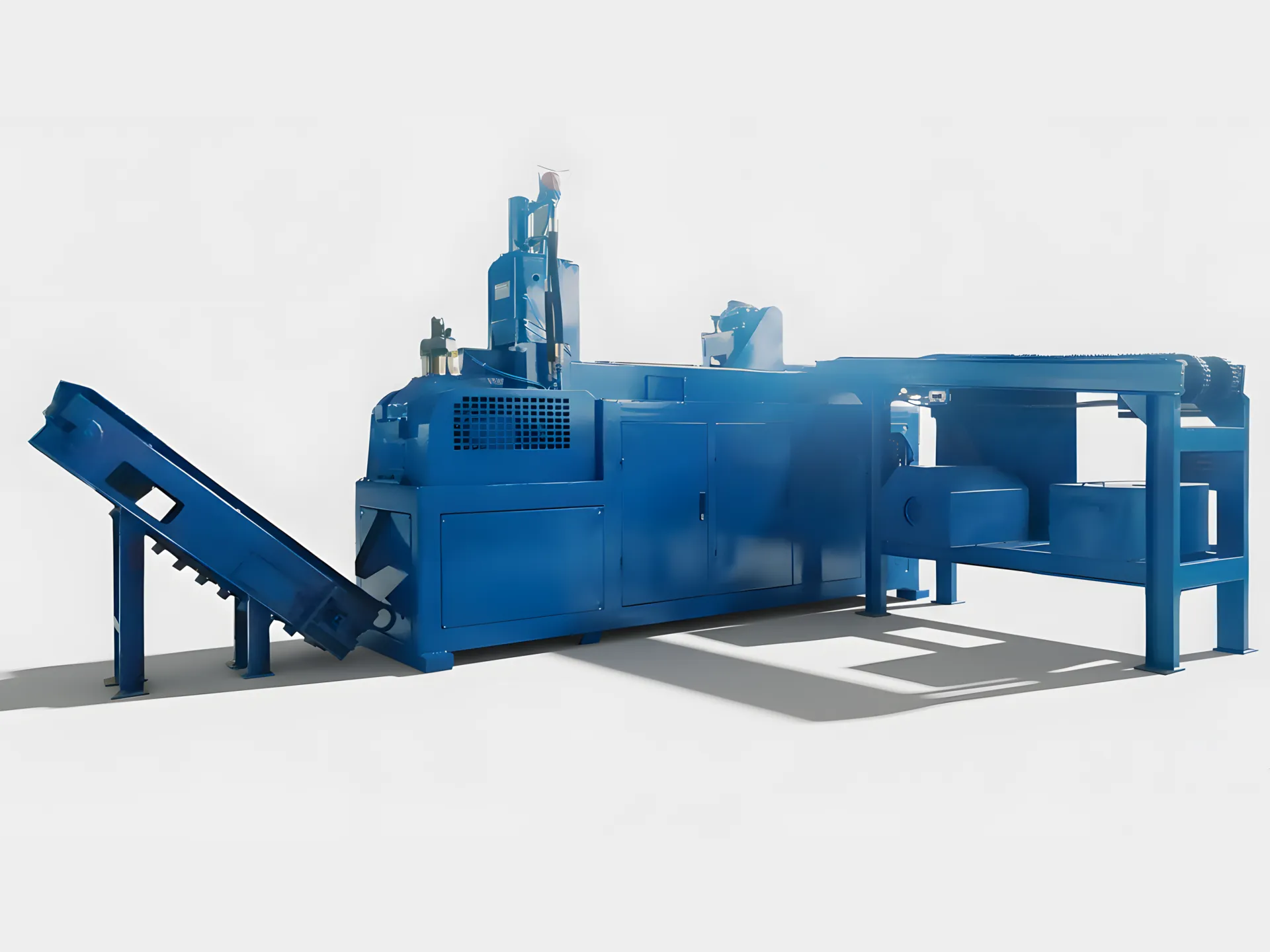

- Washing & separation (friction, float‑sink, hot wash)

- Dewatering & thermal drying

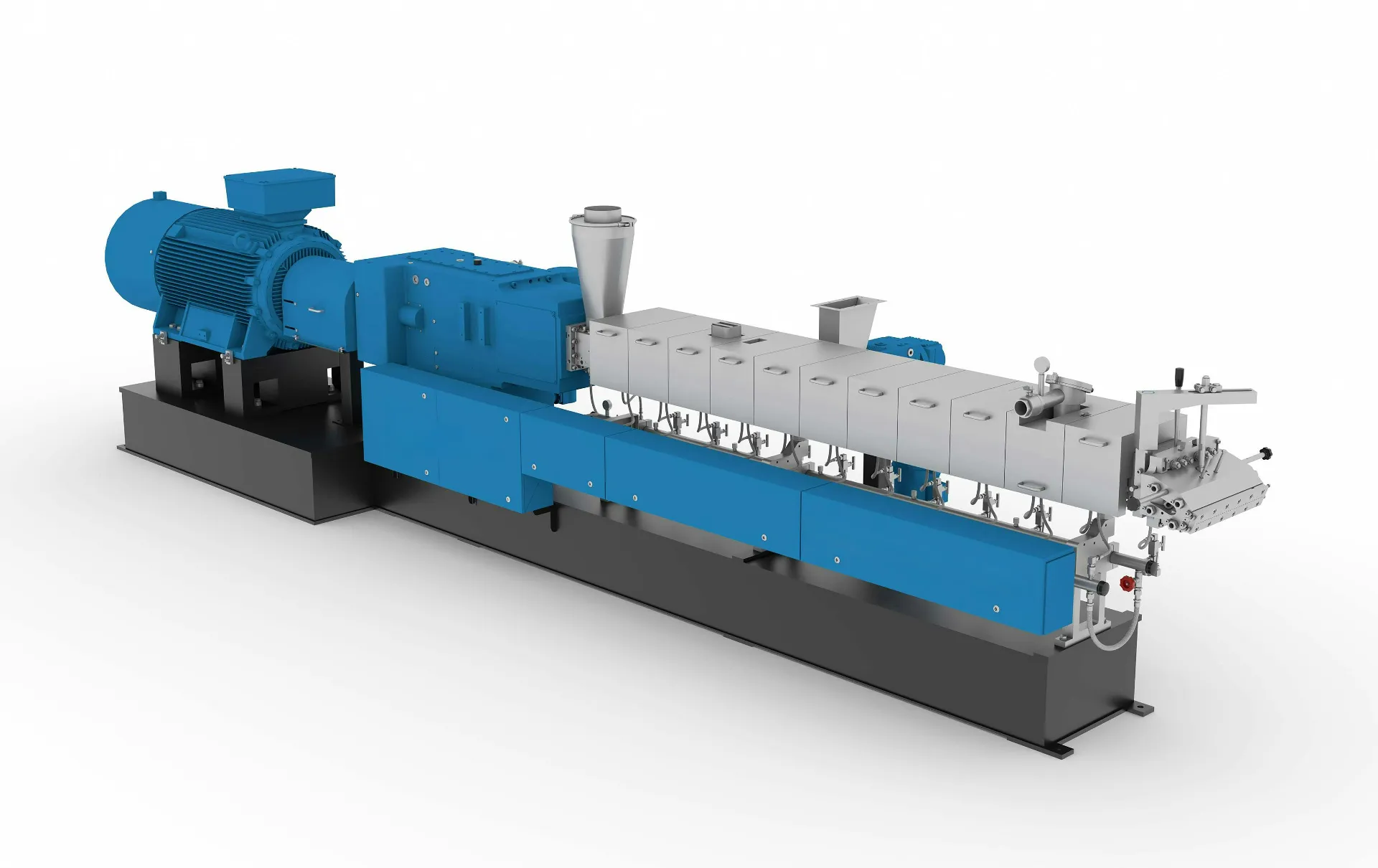

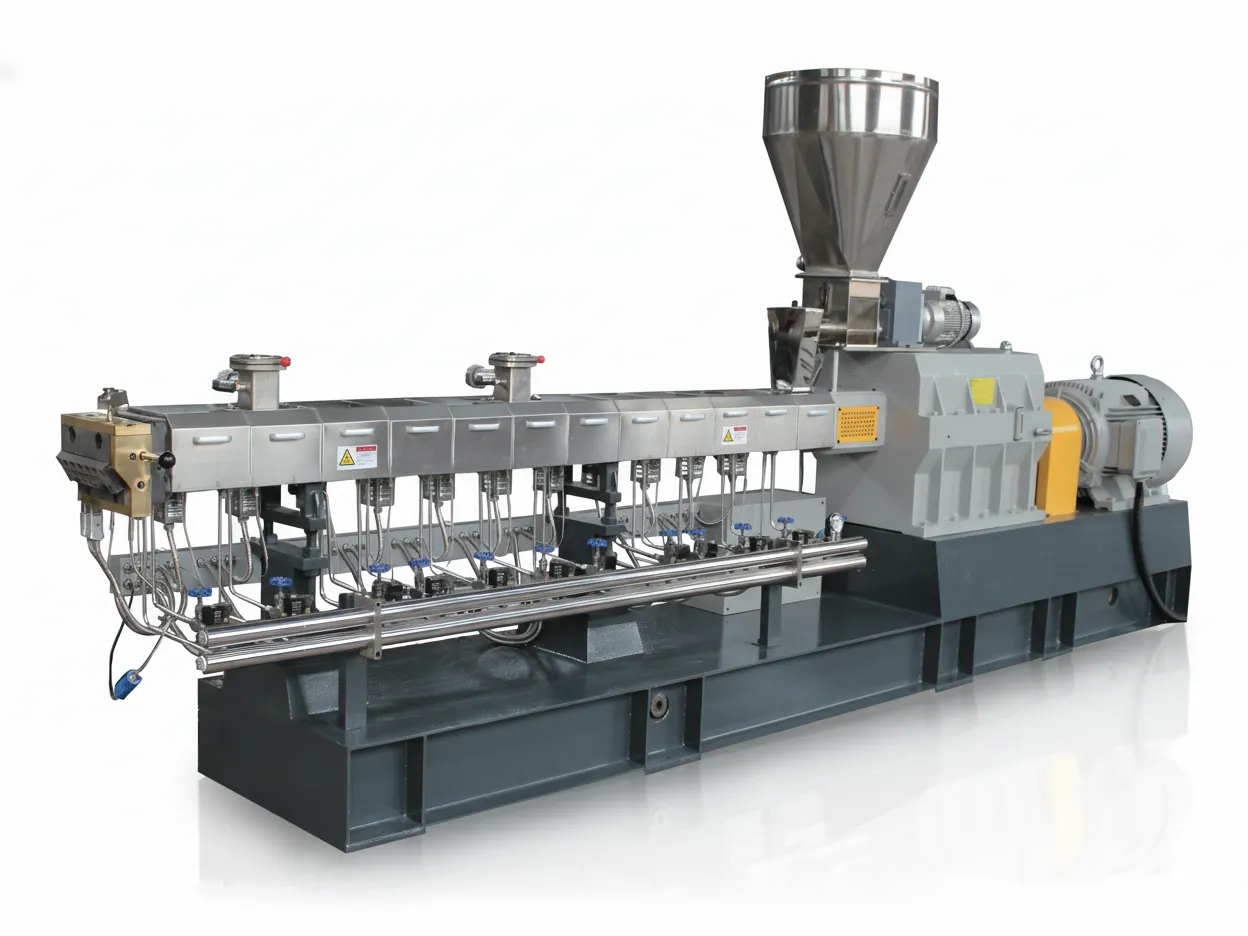

- Extrusion, filtration, degassing & pelletizing

Why Choose Our Integrated Lines

Clear advantages from intake to finished pellets: higher uptime, lower handling and consistent product.

Reliable Throughput

Line‑level orchestration keeps material moving smoothly and maximizes usable output.

Modular & Scalable

Start with essentials and expand as you grow — each module tuned to your feedstock.

Turnkey Delivery

From design to installation, commissioning and operator training — one accountable team.

Consistent Pellet Quality

Multi‑stage purification, fine filtration and controlled degassing help stabilize color and MFI.

From Pain Points to Results

Typical challenges operators face — and how the line converts them into consistent output and lower costs.

How It Works

End‑to‑end process engineered to deliver clean, dry flakes and uniform pellets.

Sorting & Separation

Remove metals, glass, paper and separate by polymer/color for higher purity. View equipment.

Size Reduction

Shredders and granulators create uniform flakes, improving downstream cleaning efficiency. View machines.

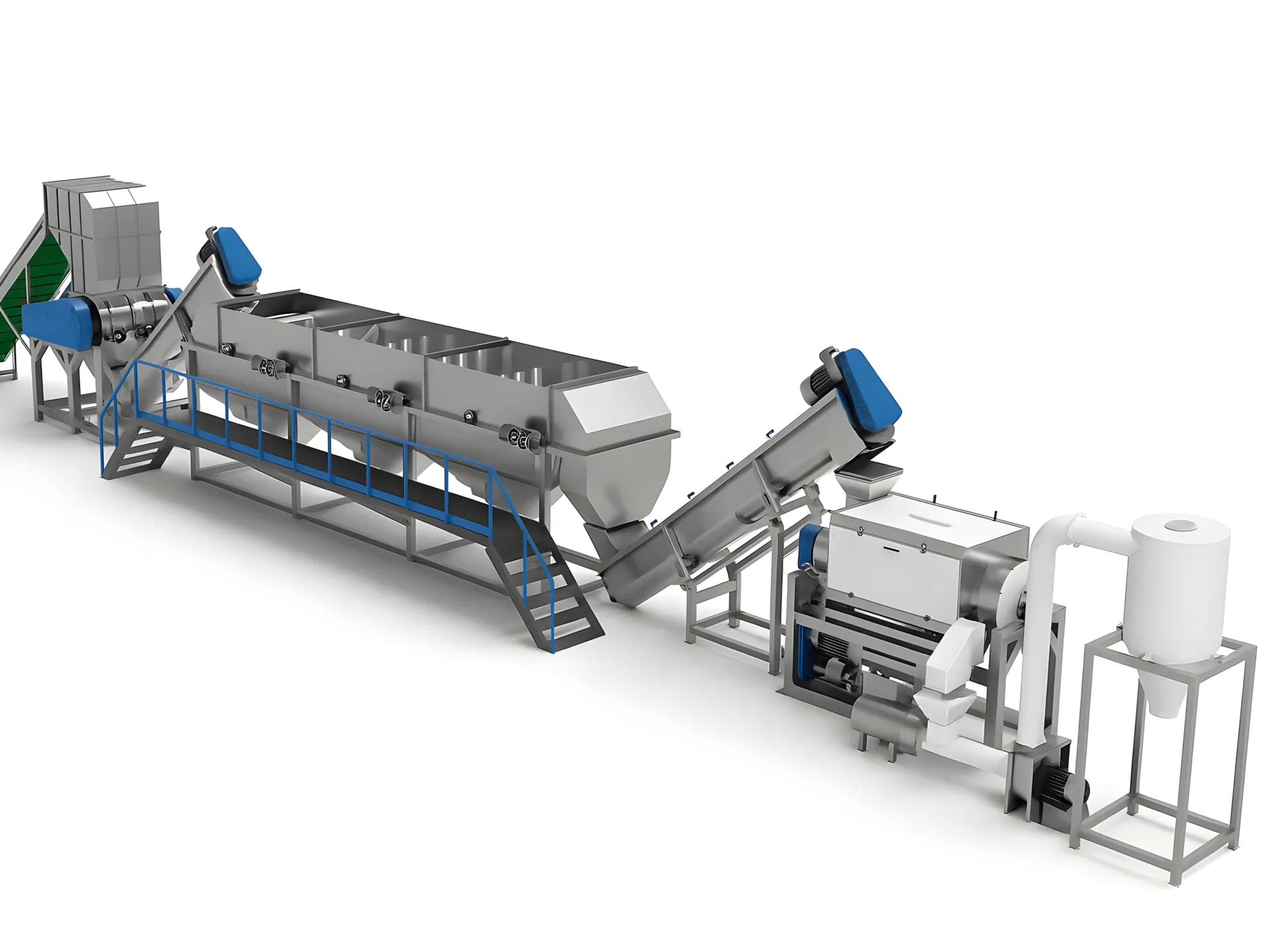

Washing & Cleaning

Friction washers, float‑sink and hot wash remove labels, glue and residues. View systems.

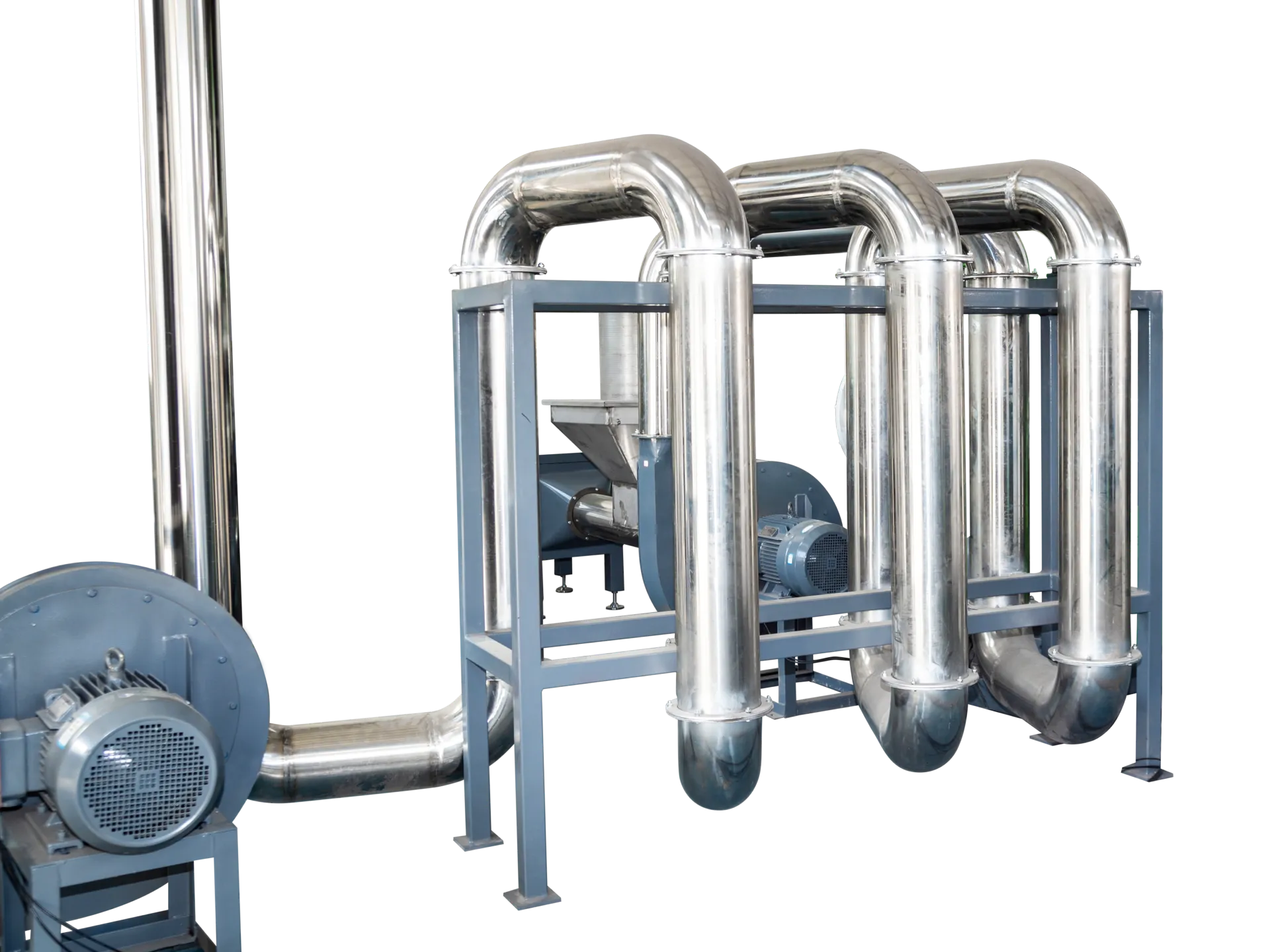

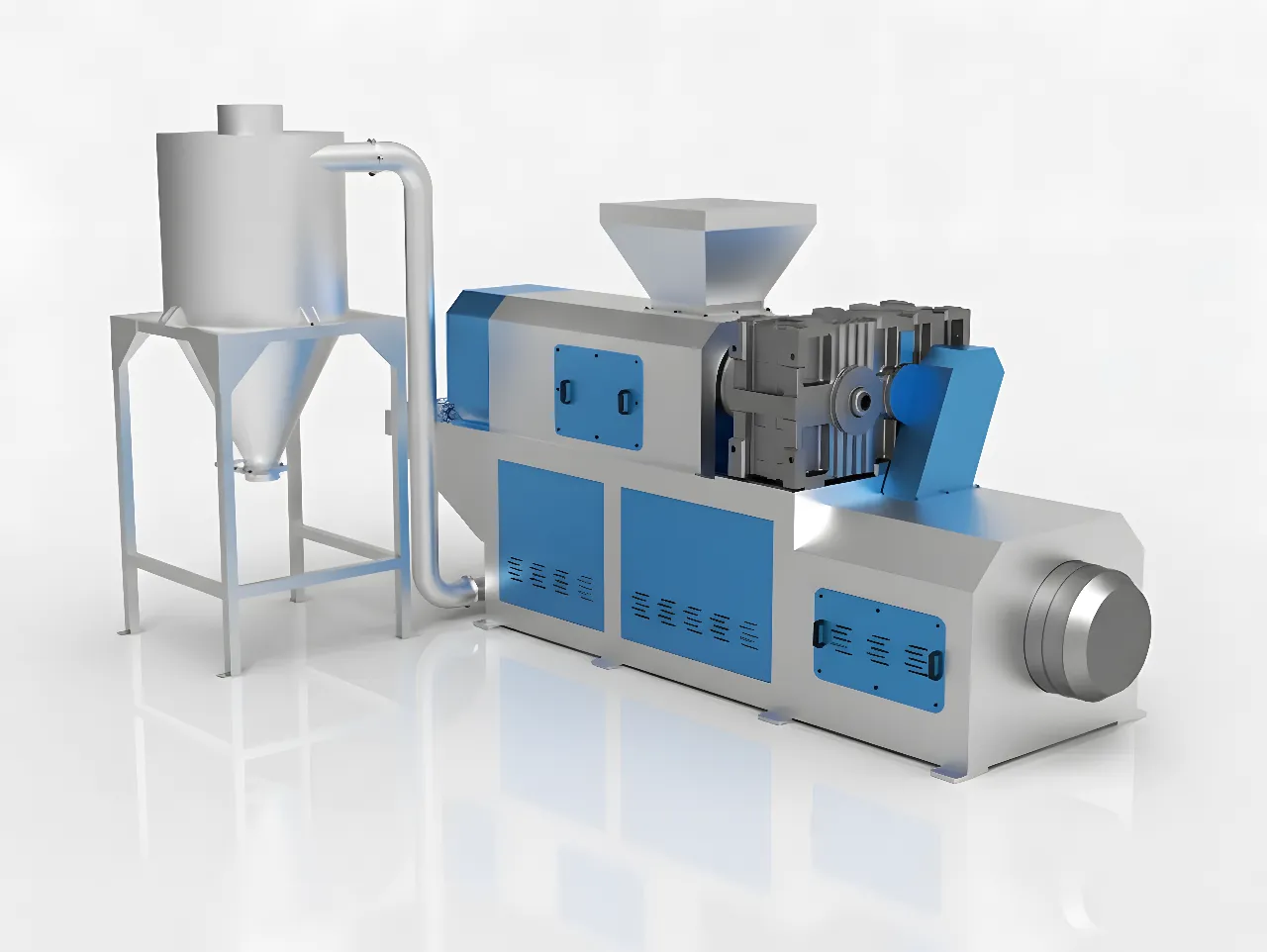

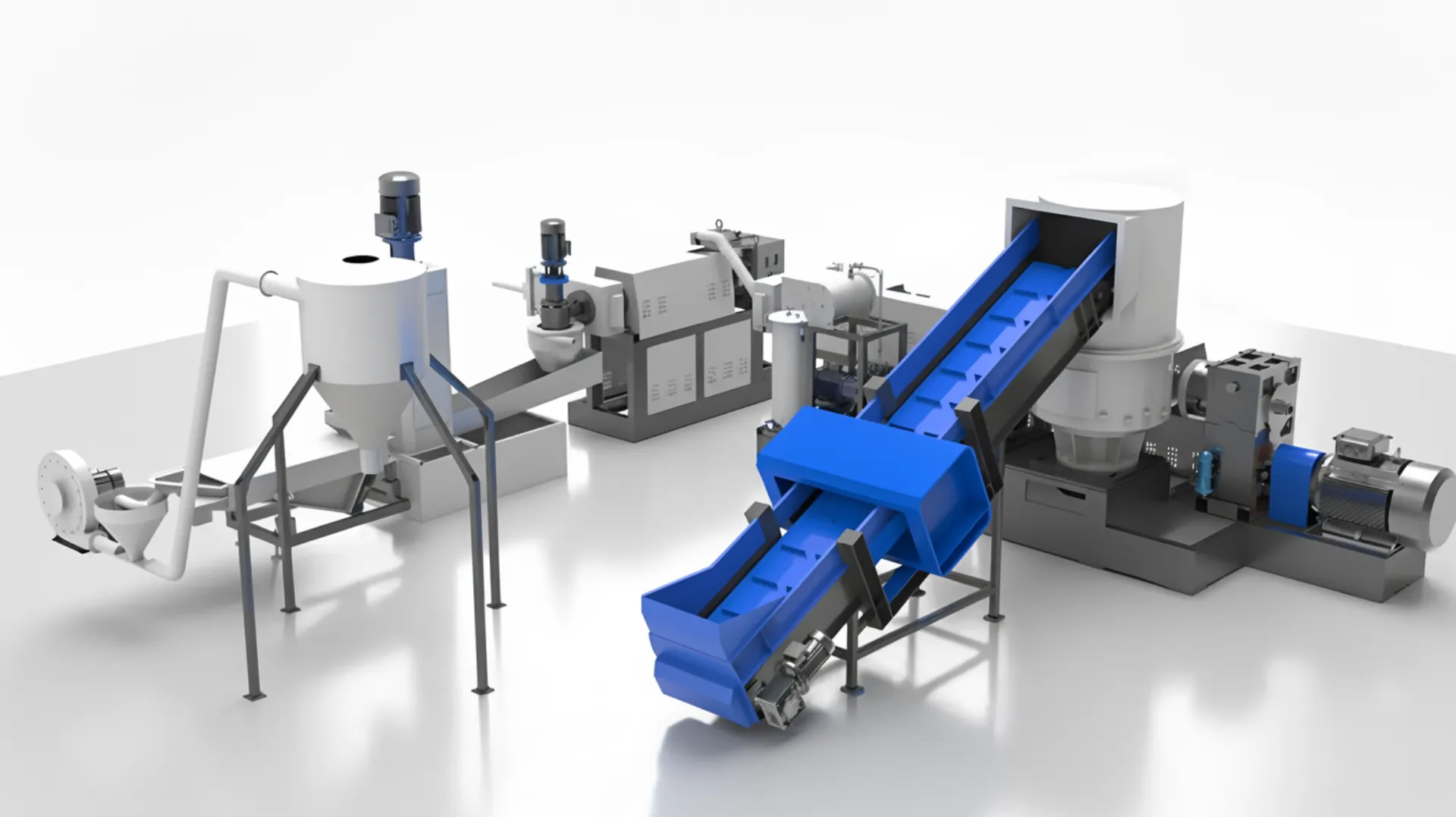

Dewatering & Drying

Centrifugal dewatering and thermal drying reach moisture targets for extrusion. View dryers.

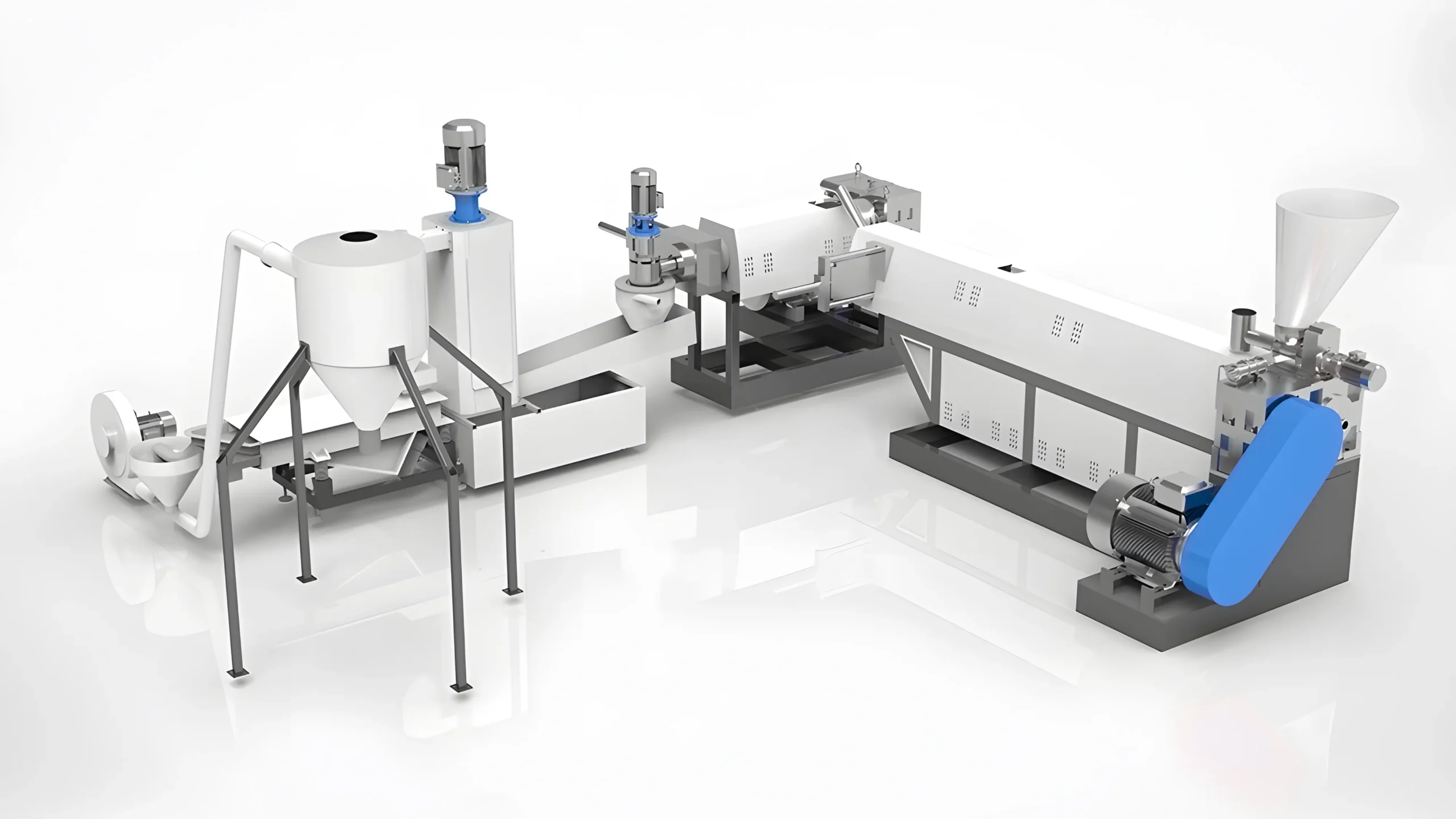

Melting & Pelletizing

Extrusion with filtration, degassing and strand cutting for uniform, market‑ready pellets. See pelletizers.

Key Components

Belt Conveyor

Continuous, enclosed material transfer between modules to reduce spillage, dust and manual handling.

Trommel Screen (Sorting)

Removes large contaminants and pre‑classifies material by size to stabilize downstream flow and improve purity.

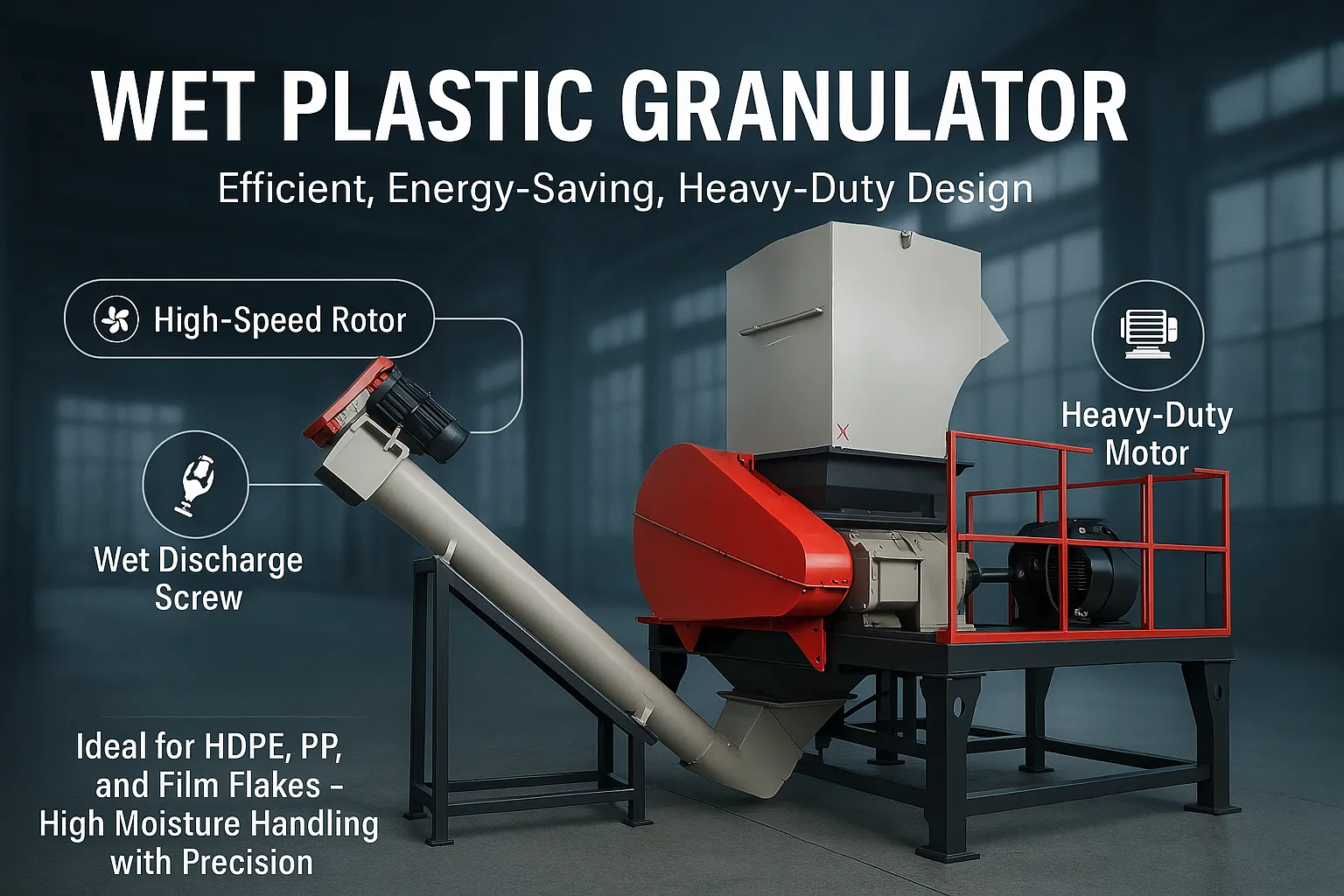

Plastic Granulator

High‑throughput size reduction producing uniform flakes to boost washing efficiency and lower energy per ton.

Friction Washer & Washing System

Friction cleaning, float‑sink separation and hot wash remove labels, glue and organics for high‑purity flakes.

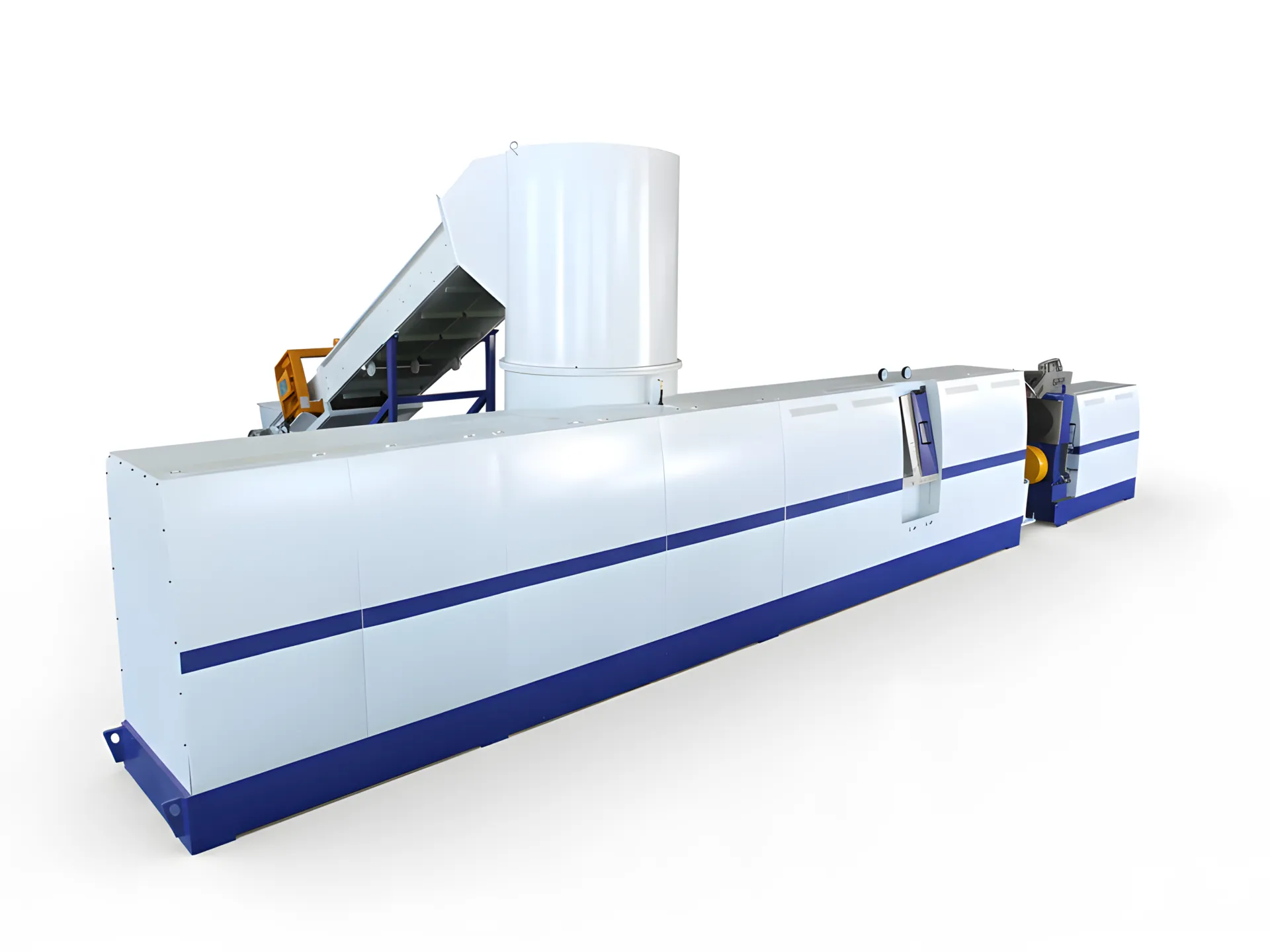

Dewatering Centrifuge & Dryers

Mechanical dewatering followed by thermal drying to reach moisture targets for extrusion and pelletizing.

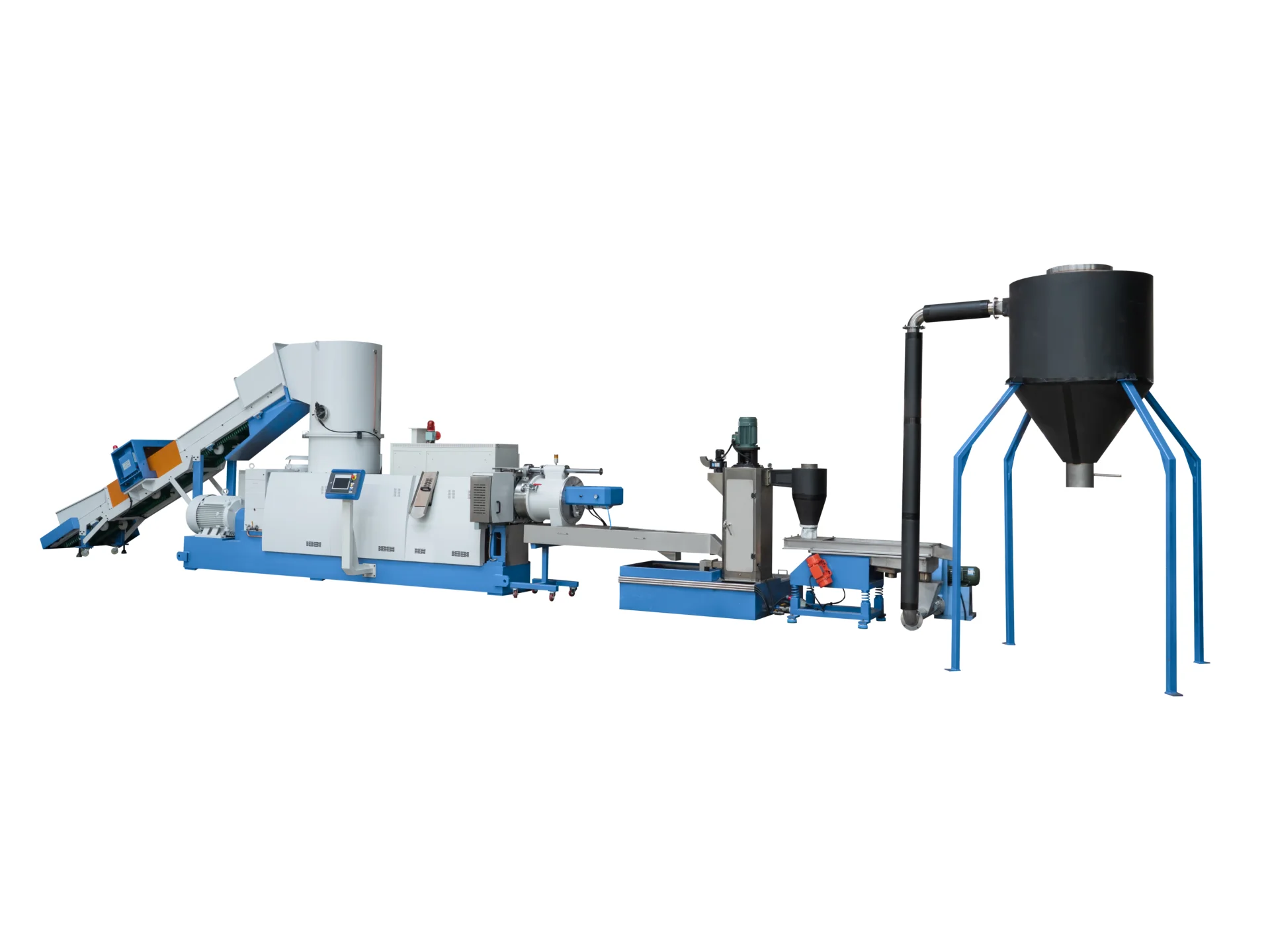

Pelletizing Line (Cutter‑Compactor)

Integrated cutter‑compactor, filtration and degassing deliver uniform pellets with stable MFI and color.

Materials We Process & Typical Capacities

Compatible Plastics

- PET bottles and flakes (food/non‑food grade)

- HDPE/PP rigid containers, caps and crates

- PE film, agricultural film, raffia & woven bags

- Mixed post‑consumer and post‑industrial streams

Line Capacities

Compact line for limited floor space

Balanced throughput & energy efficiency

High‑throughput plant for scale

Drying targets for extrusion‑ready flakes

Our Recycling Plants in Action

From compact lines to large‑scale facilities — proven performance.

Customer Success Stories

PE Film → Recycled Pellets, Europe

Compact 800 kg/h line with hot washing and cutter‑compactor pelletizing.

PET Bottles → RPET Flakes, Asia

1200 kg/h with label remover, friction wash, dewatering and crystallization.

Frequently Asked Questions

Can the line be customized for my specific type of plastic waste?

Absolutely. Our core strength is modular design. We will analyze your raw materials (e.g., highly contaminated agricultural film vs. clean factory scraps) and customize each module—from the type of shredder to the intensity of the washing phase—to achieve the best results.

What is involved in a "turnkey" project?

A turnkey project means we handle everything for you. This includes consultation, custom plant layout, manufacturing, shipping, on-site installation, commissioning, and comprehensive training for your operational team.

What is the typical ROI for a complete plastic recycling line?

The Return on Investment (ROI) depends on factors like local cost of plastic waste, labor costs, and the market price for recycled pellets. Many of our clients achieve ROI within 18-36 months. We can provide a detailed ROI analysis based on your specific situation.

What are the lead time and installation timeline?

Manufacturing usually takes 6–12 weeks based on configuration. Installation and commissioning typically require 1–2 weeks for compact lines and 3–6 weeks for larger turnkey projects, including on‑site training.

Are you the manufacturer or a trading company?

We are the original manufacturer based in China with ISO 9001 and CE compliance. Factory visits by appointment are welcome.

Do you ship worldwide? Do you install in India/Sri Lanka?

Yes. We export to 30+ countries and provide on‑site installation, commissioning and operator training in India and Sri Lanka.

Do you have reference plants near me?

Yes. We can share nearby installations and arrange site visits with customer approval.

How much does a plastic recycling machine cost?

Pricing depends on throughput, contamination level, washing intensity, filtration/degassing, automation and material type. Send your material and capacity to receive a tailored quote within 24 hours.

What is the plastic recycling machine price in India?

Final price depends on configuration plus freight, duties and GST. We quote in USD/INR and can provide CIF or DDP to major ports/cities on request.

Where is your factory located? Can I visit?

Our factory is located in China. Factory and test‑line visits can be scheduled in advance.

What certifications do your machines meet?

CE compliant with ISO 9001 quality management system.

What Our Customers Say

Trusted by operators across 30+ countries.

Get a Custom Quote

Tell us about your materials, capacity targets, and site conditions. Our engineering team will propose a tailored plastic recycling line that maximizes ROI.

Explore Individual Machines

Select modules to customize your line.