PP/PE Regrind Washing & Pelletizing Line

Convert contaminated PP/PE film and regrind into high‑quality pellets with a clean, energy‑efficient process designed for consistent output and low moisture.

Why Choose This Line

Clean pellets, stable throughput, and flexible configurations that fit your materials and scale.

High Purity Output

Meticulous washing and separation deliver clean pellets suitable for demanding applications.

Energy Efficient

Optimized modules and smart layout reduce energy consumption and OPEX.

Modular & Customizable

Configure to match contamination levels, space constraints, and target capacity.

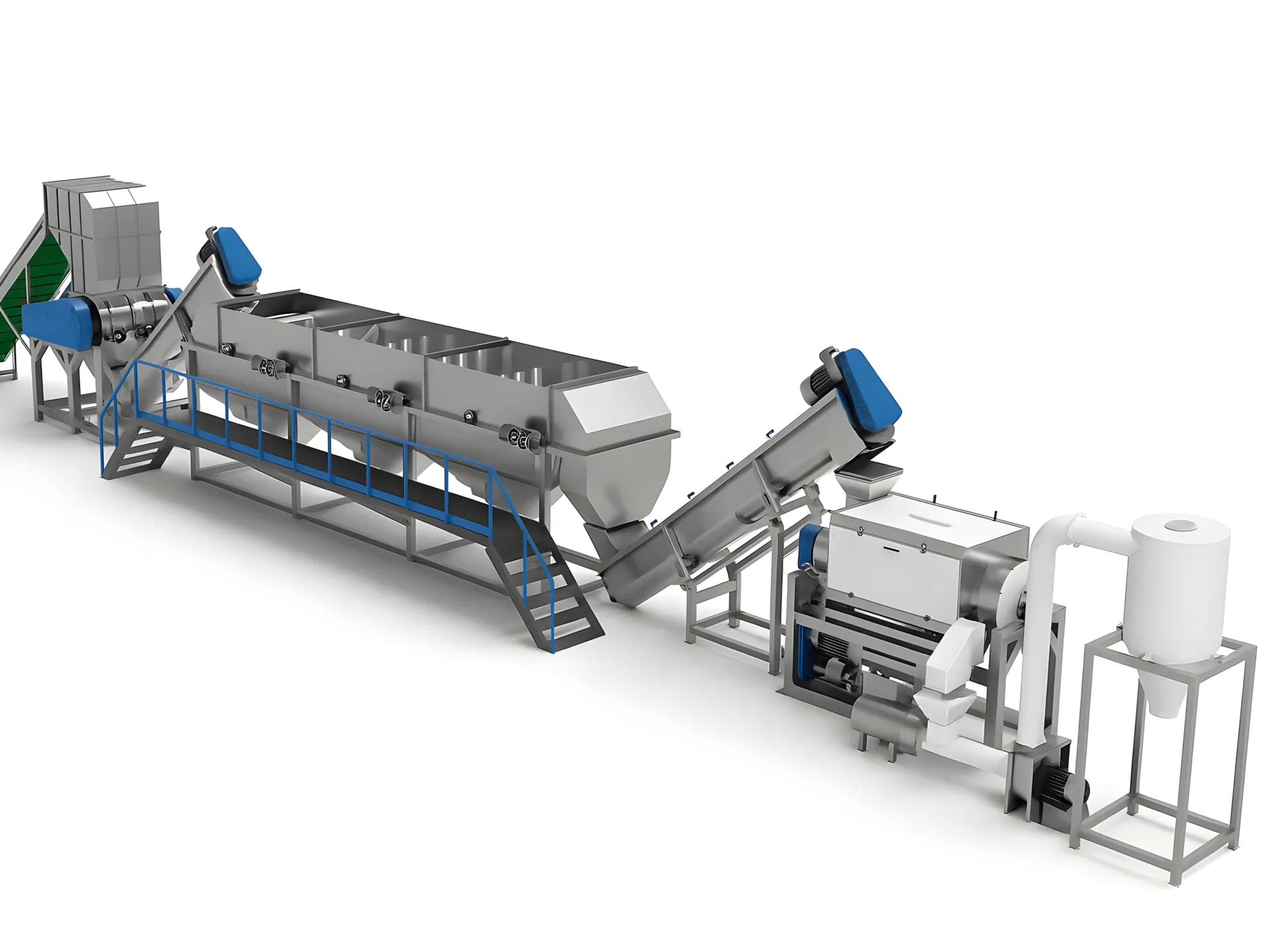

From Waste to Worth: Process Flow

Input & Pre‑size Reduction

Shredded PP/PE film and regrind prepared to stable, conveyable sizes.

Intensive Washing

Friction cleaning rapidly removes labels, paper, and surface contaminants.

Sink/Float Separation

Density separation ejects heavy impurities while retaining PP/PE film.

Mechanical & Thermal Drying

Centrifugal dewatering or squeezer + hot air pipes achieve ≤ 3–5% moisture.

Pelletizing

Water‑ring system melts, filters, and cuts into round pellets ready for reuse.

Key Line Components

- Plastic Shredder MachineRobust single‑shaft shredder pre‑cuts film to prevent tangling and blockages.

- Plastic Granulator (Wet Grinding)Size reduction to ~10–20 mm with water flushing for pre‑wash.

- Friction WasherHigh‑speed scrubbing (≈1000 RPM) removes embedded dirt, labels, and paper fibers.

- Sink/Float Separation TankWater‑based density separation to discharge stones, metals, and grit.

- Centrifugal DewateringSpins off surface water to cut energy use before thermal drying.

- Screw Press Dewatering (Optional)High‑pressure squeezing can replace both centrifugal and thermal stages in some setups.

- Thermal Dryer & CycloneHot‑air tube drying and cyclone cooling remove residual moisture and fines.

- Product SiloClean, dry flakes buffer for stable pelletizer feeding.

- Plastic Pelletizing MachineWater‑ring pelletizer melts, filters, and cuts to uniform, high‑quality pellets.

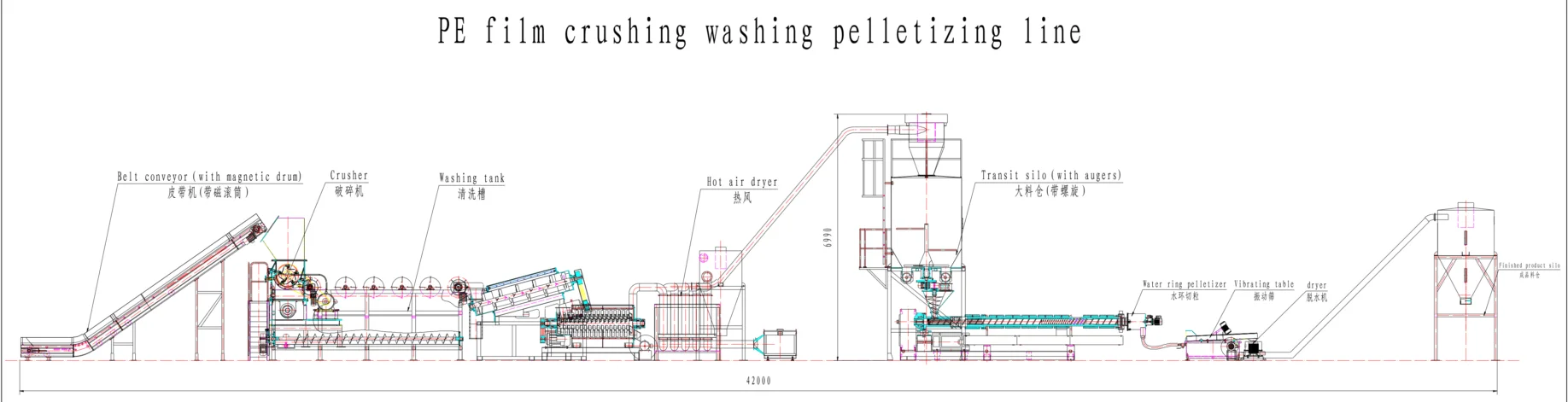

Typical Layout

A compact, modular arrangement suitable for 300–2000 kg/h lines with upgrade paths.

Request a Quotation

Share your input materials, contamination level, and target throughput. We’ll propose a tailored configuration and layout.

FAQs

What capacities are available?

Standard configurations cover 300–2000 kg/h. We tailor line modules to your material mix, contamination, and staffing to achieve stable throughput.

Power and compliance for EU/US?

EU setups typically use 400V/50Hz, US 460V/60Hz (others on request). Machines meet CE requirements; UL-listed components and English HMI are available.

Water usage and recycling?

Closed-loop water systems with filtration minimize consumption and discharge. We can integrate DAF and sludge handling to fit local regulations.

Installation, commissioning, and training?

We provide layout drawings, remote/onsite commissioning, and operator training. Typical installation takes 2–4 weeks depending on line size.

Lead time and shipping?

Lead time is usually 6–12 weeks ex‑works depending on configuration. We support FOB/CIF and arrange crating suitable for sea freight.

Comments are closed.