Vertical Mixing Dryer

The ultimate auxiliary machine for your production line. Our vertical mixing dryer expertly dries, blends, and colors plastic granules in one efficient, space-saving unit, ensuring a consistent, high-quality feed for your extruders and injection molders.

Streamline Your Material Preparation

Replace multiple machines with a single, highly efficient solution designed to improve your workflow, save energy, and deliver perfectly prepared materials every time.

Simultaneous Drying & Mixing

This dual-purpose workhorse combines hot air drying with continuous blending, ensuring granules are both moisture-free and perfectly homogenized with colorants or masterbatch in a single cycle.

Uniform & Consistent Results

The unique spiral lifting and centrifugal dispersing action guarantees that every granule is evenly exposed to heat and mixed thoroughly, eliminating clumps and color inconsistencies.

Energy-Efficient Design

Features a dual-layer insulated barrel and an efficient hot air blower to minimize heat loss, significantly reducing energy consumption compared to separate drying and mixing units.

The Working Principle

Lifting

A central screw auger gently lifts plastic granules from the bottom to the top of the stainless steel barrel.

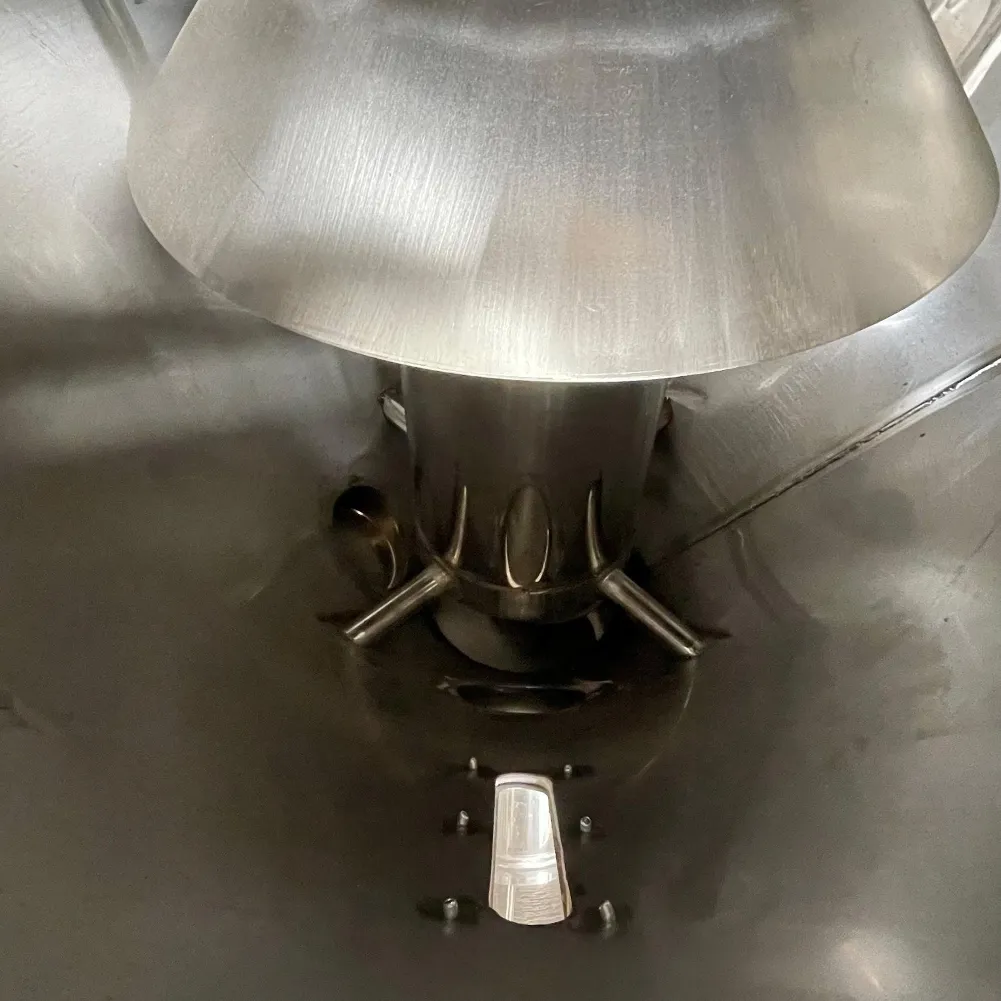

Mixing

At the top, centrifugal force disperses the granules in an "umbrella" pattern, cascading them down for a thorough mix.

Drying

Simultaneously, precisely heated air blows upwards, efficiently removing moisture from the cascading granules.

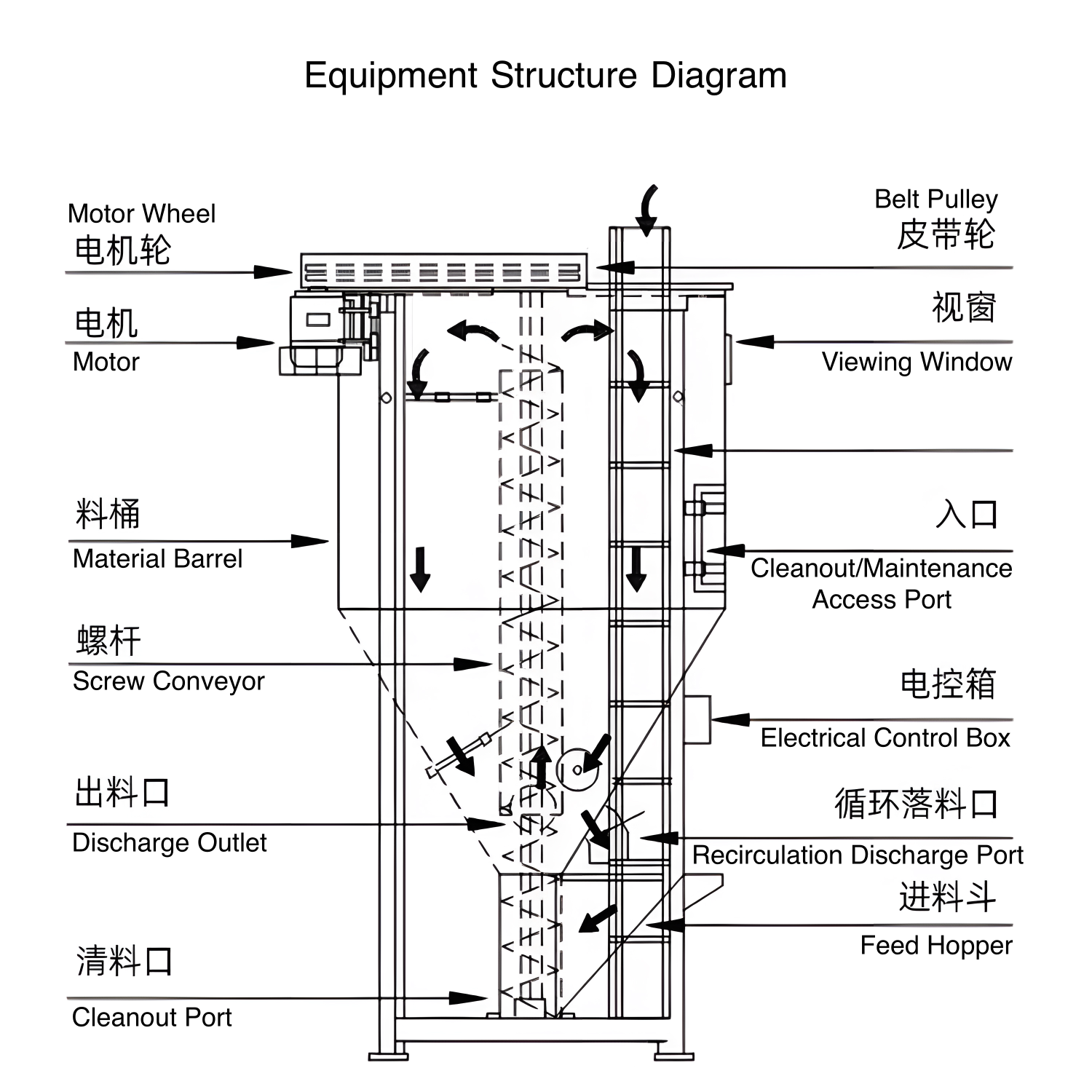

Machine Structure

Technical Specifications

| Model Series | EC-VMD Series |

|---|---|

| Capacity Range | 200 kg to 5000 kg (Customizable) |

| Barrel & Blade Material | Stainless Steel (SUS304) |

| Heating Method | Electric Heating Rods |

| Temperature Control | PID Intelligent Controller |

| Timer Control | 0 - 30 Minutes (Adjustable) |

| Key Features | Insulated Barrel, Safety Interlocks, Low Feed Port |

| Mobility | Sturdy base with optional casters |

Ideal Applications

Common use cases where the Vertical Mixing Dryer excels in preparing clean, consistent, and dry feedstock.

PET/HDPE/PP Flake Drying

Removes surface moisture effectively from washed flakes to stabilize downstream extrusion quality.

Granule & Pellet Mixing

Blends virgin pellets with regrind to a homogeneous mixture for consistent melt and color.

Masterbatch/Additive Blending

Uniformly disperses masterbatch and additives to avoid streaks and color variation.

Pre‑processing for Extrusion

Prepares a stable, dry, and evenly mixed feed for extrusion or injection lines.

Equipment Showcase

Frequently Asked Questions

Can this machine mix and dry at the same time?

Yes, that is its primary advantage. The machine circulates the plastic granules mechanically for mixing while simultaneously blowing precisely heated air through them for drying. This dual action happens in a single, efficient cycle, saving time, space, and energy.

What types of plastic materials is this dryer suitable for?

This machine is ideal for a wide variety of plastic granules and pellets, including PP, PE, PVC, ABS, PS, and more. It is perfect for blending virgin material with masterbatch, colorants, or regrind, and for pre-drying materials before extrusion or injection molding.

How is the temperature controlled?

The system is equipped with a PID intelligent temperature controller. This allows you to set a precise target temperature for the drying process. The controller automatically manages the stainless steel heating elements to maintain that temperature accurately throughout the cycle.

What drying temperature range and cycle time should I use?

Typical ranges: PP/PE 80–110°C for 10–30 minutes; ABS/PS 80–95°C for 10–20 minutes; PET 120–160°C for 20–40 minutes. Actual settings depend on initial moisture, flake size, and load volume. Start at the low end and adjust based on outlet moisture and color stability.

How do I clean the machine when changing materials?

Stop heating and discharge material, open the inspection door, and wipe contact surfaces. Then run for 2–3 minutes with warm air to purge residues. SUS304 contact parts resist staining and make wipe-down fast.

What are the installation and power requirements?

3‑phase 380–480V, 50/60Hz depending on region/model. Provide adequate ventilation; connect the hot‑air outlet to a duct or cyclone if possible to capture fines and moisture. Reserve 0.5–1 m clearance around the machine for maintenance.

Streamline Your Production Line Today

Contact our team to discover how a Vertical Mixing Dryer can improve the quality and efficiency of your plastic processing. We provide customized solutions to fit your exact capacity and material needs.