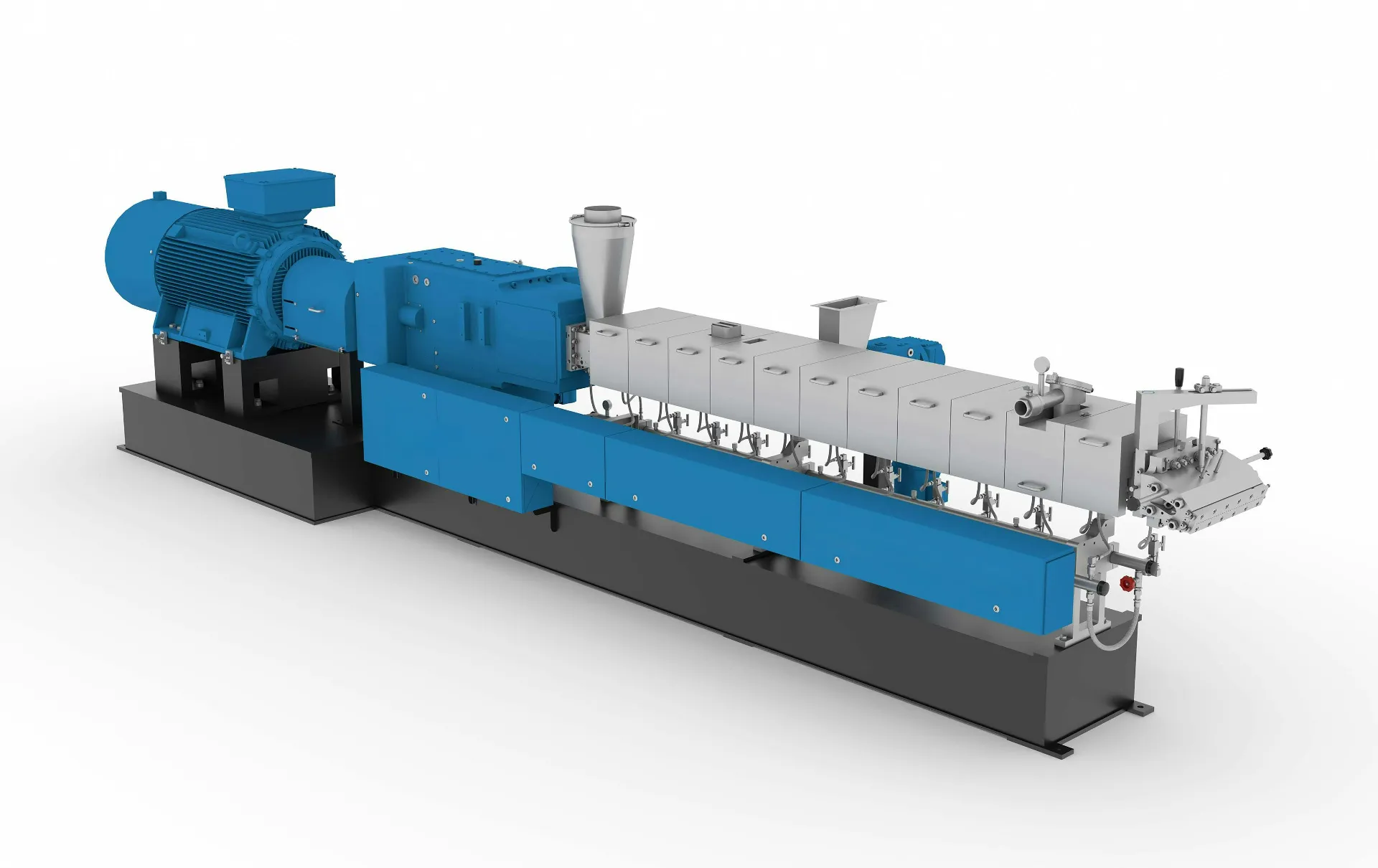

Sistema de extrusión de doble husillo

Una plataforma de doble tornillo corrotante modular y confiable para fusión estable, transporte y extrusión continua, ideal para perfiles, tuberías, láminas y procesamiento de polímeros en general.

Solicitar cotizaciónProducción estable para la producción diaria

Este sistema de extrusión de doble tornillo de uso general se centra en un rendimiento de extrusión fiable y un mantenimiento sencillo. Para procesos intensivos de mezcla, desvolatilización, filtración y peletización (una línea completa de compuestos), opte por una línea de peletización especializada.

Características principales

Diseño modular de “bloques de construcción”

Los elementos de tornillo flexibles y los barriles modulares adaptan la extrusora a sus requisitos de material y producto.

Opciones de caja de cambios

Serie de torque múltiple (estándar a alto torque) con acoplamiento de seguridad opcional para un funcionamiento estable a largo plazo.

Tornillos autolimpiables

El diseño de tornillo de malla completa reduce los residuos y ayuda a prevenir el sobrecalentamiento localizado durante la extrusión continua.

Control preciso de la temperatura

Las zonas de calentamiento independientes ayudan a mantener una viscosidad de fusión estable y dimensiones del producto consistentes.

Soporte de alimentación y dosificación

Compatible con alimentadores volumétricos y de pérdida de peso, además de configuraciones de alimentación principal/lateral.

Fácil mantenimiento

Los insertos de aleación reemplazables y las secciones de cañón funcionales simplifican el servicio y reducen el tiempo de inactividad.

Cómo funciona

- Alimentación: Los pellets/polvos se alimentan a través de la tolva principal; la alimentación lateral está disponible cuando es necesario.

- Fusión y plastificación: Los tornillos gemelos calientan y funden el material con una zona de temperatura estable.

- Mezcla y transporte: El material se transporta a la matriz manteniendo un flujo de fusión constante.

- Ventilación (opcional): Elimina la humedad y los componentes volátiles para lograr una extrusión más limpia y menos defectos en la superficie.

- Conformado de matrices: La masa fundida se moldea a través de una matriz para formar un perfil, un tubo, una lámina u otros productos.

- Manejo posterior: La calibración/enfriamiento, el transporte y el corte están integrados según su línea de productos.

Aplicaciones típicas

Perfiles y WPC

Perfiles de PVC y WPC para materiales de construcción y componentes industriales.

Extrusión de tuberías

Suministro estable de material fundido para sistemas de tuberías de PVC/PE con calibración y arrastre aguas abajo.

Láminas y tableros

Líneas de extrusión de láminas/tableros que requieren un control de espesor constante.

Compuestos para cables (extrusión)

Soporte de extrusión para materiales de cable con zonificación de alimentación y temperatura adecuada.

Especificaciones técnicas

| Especificación | Valor |

|---|---|

| Diámetro del tornillo | 50–150 milímetros |

| Relación L/D | Hasta 68:1 |

| Velocidad máxima del tornillo | Hasta 600 rpm |

| Potencia del motor | 55–450 kW |

| Capacidad Máxima | 150–2000 kg/h |

*Las especificaciones finales dependen del material, la matriz y la configuración posterior.

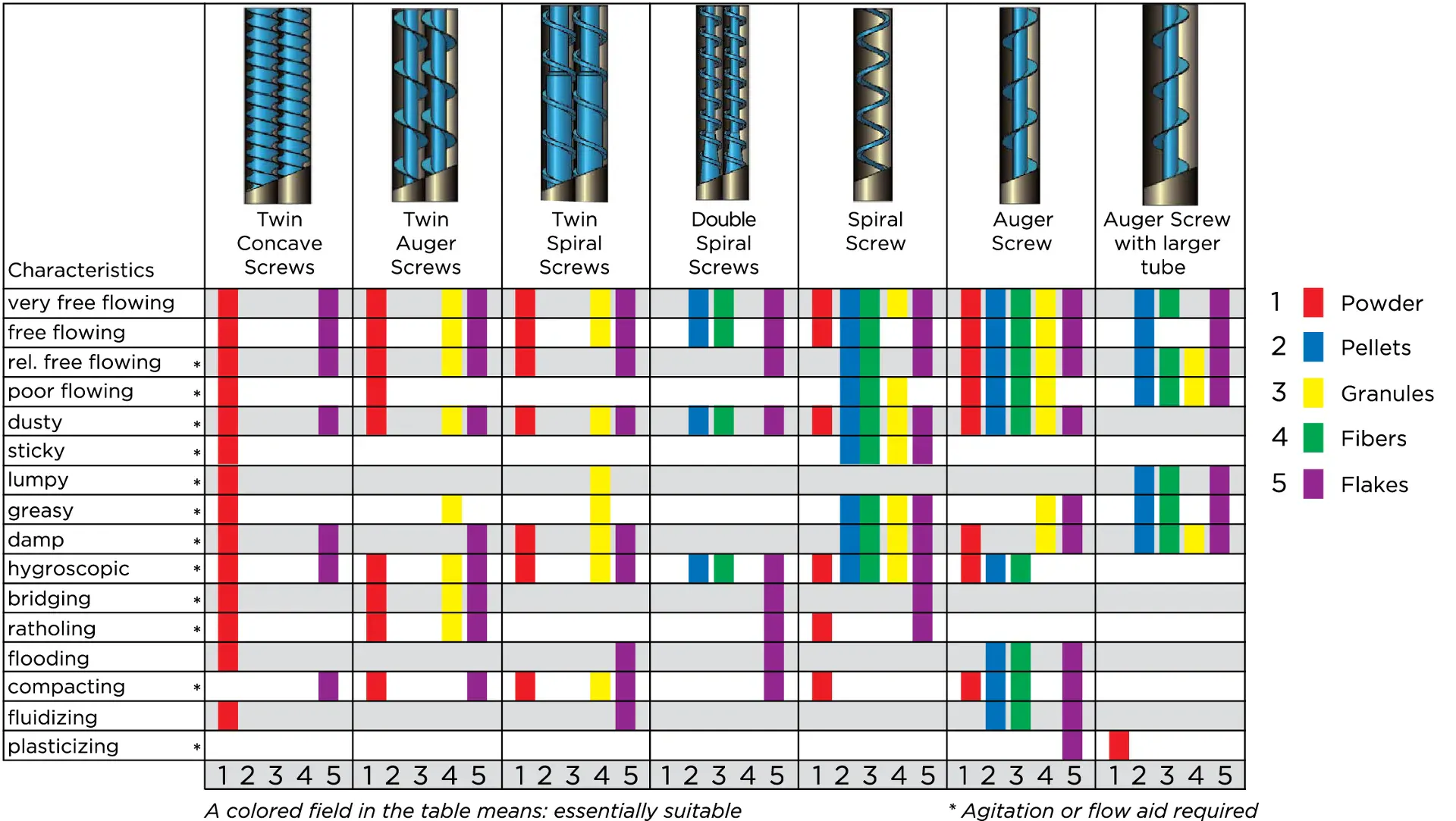

Varias configuraciones de tornillos

Ver el sistema de extrusión

Un breve recorrido por la plataforma extrusora de doble tornillo y su configuración modular.

Garantía e instalación

Garantía limitada de 1 año

Todos nuestros sistemas de extrusión incluyen una garantía limitada integral de un año.

Soporte de puesta en servicio

Brindamos orientación sobre la instalación, sugerencias de configuración de parámetros y soporte posventa para una producción estable.

Preguntas frecuentes

¿Qué materiales puede procesar este sistema de extrusión de doble tornillo?

Se utiliza comúnmente para PVC y otros termoplásticos, según la configuración. Comparta su polímero, aditivos y producto objetivo (perfil/tubería/lámina) para obtener una configuración recomendada.

¿Cómo selecciono el diámetro del tornillo y la relación L/D?

La selección depende de su rendimiento objetivo, las necesidades de estabilidad de la masa fundida, el tipo de matriz y las dimensiones del producto. Dimensionamos el sistema según su rendimiento y los requisitos de su aplicación.

¿Ofrecen opciones de ventilación o vacío?

Sí. La ventilación y el vacío se pueden configurar para eliminar la humedad y los volátiles, mejorando la calidad de la superficie y reduciendo las burbujas.

¿Es posible personalizar el sistema con equipos posteriores?

Sí. Podemos combinar matrices, tanques de calibración/enfriamiento, sistemas de arrastre y corte para construir una línea de extrusión completa para su producto.

¿Cuándo debería elegir una línea de peletización de compuestos dedicada?

Si su objetivo principal es una mezcla/composición intensiva con filtración y peletización en pellets uniformes (por ejemplo, masterbatch o compuestos rellenos), una línea de peletización de compuestos dedicada es más adecuada.

Solicitar una propuesta de configuración

Comparta su material, producto objetivo (perfil/tubería/lámina) y capacidad. Le recomendaremos el diámetro del tornillo, la longitud/diámetro, la caja de engranajes, el sistema de ventilación y los equipos posteriores.