The profitability of a recycling line is often determined by a single consumable: the Rotary Knife. A set of blades that dulls in 200 hours versus one that lasts 800 hours fundamentally changes your OpEx. This technician’s guide explores the metallurgy behind industrial shredder blades and how to select the right steel for your waste stream.

Related equipment: single shaft shredder.

The Chemistry of Cutting: Understanding Steel Grades

Not all “Hardened Steel” is equal. The industry standard relies on Cold Work Tool Steels, characterized by high Carbon and Chromium content.

1. D2 Steel (AISI D2 / DIN 1.2379)

- Composition: 1.5% Carbon, 12% Chromium.

- The Standard: D2 is the workhorse of the plastics industry. It offers a good balance of wear resistance and cost.

- Hardness: Heat-treated to 58-60 HRC.

- Best For: Clean polyolefins (HDPE, PP), PET bottles, and general plastic waste.

- Weakness: It is relatively brittle. If a heavy metal contaminant (like a hammer head) enters the shredder, D2 blades often crack or shatter.

2. DC53 (Improved Cold Work Die Steel)

- The Upgrade: A proprietary grade modified from SKD11.

- Hardness: Can reach 62-64 HRC after high-temperature tempering.

- Toughness: DC53 is approximately 2x tougher than D2. It resists chipping far better under impact.

- Best For: Tough applications like E-Scrap, Tires, and Copper Wire where shock loads are common.

3. Hardfacing (Tungsten Carbide Overlay)

- The Armor: A standard steel body welded with a Tungsten Carbide matrix pattern.

- Hardness: The carbide particles reach 70+ HRC.

- Best For: Abrasive materials like Dirty Agricultural Film (sand/silica content) or Glass-Filled Plastics.

- Trade-off: You cannot sharpen these blades easily. They are run-to-failure or require specialized re-welding.

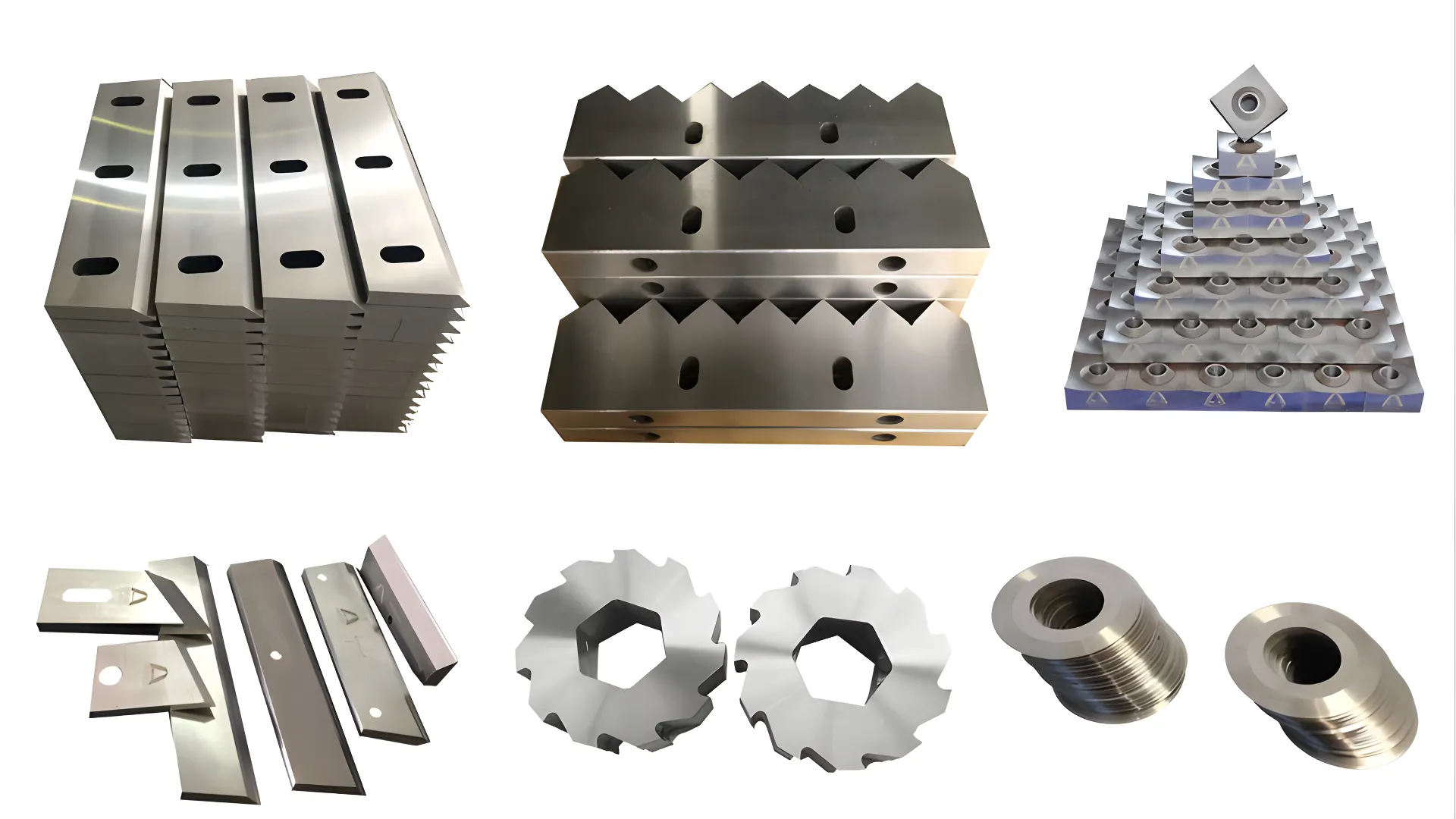

Blade Geometry & Configuration

The shape of the blade dictates the “bite.”

Rotor Knives (Moving)

- Square (4-Way): The most common design. When one edge dulls, you rotate it 90 degrees.

- Tip: Use a torque wrench when rotating. Loose bolts lead to catastrophic rotor damage.

- Hook / Hawkbill: Aggressive shape for grabbing voluminous film or fiber.

- Risk: If the hook strikes a solid object, the torque spike is massive.

Stator Knives (Stationary)

- These act as the “anvil.” They should generally be slightly softer (2-3 HRC points lower) than the rotor knives. This ensures that if a crash occurs, the cheaper/easier-to-change stator takes the damage, saving the expensive rotor.

Heat Treatment: The Invisible Variable

Two blades can look identical but perform differently due to Tempering.

- Standard Tempering: Heating to ~200°C. Good hardness, lower toughness.

- Vacuum Hardening + Cryogenic Treatment: Freezing the blade to -196°C after hardening transforms retained austenite into martensite. This increases wear life by 20-30% without making the blade more brittle. Always ask your supplier if they use Cryo.

Maintenance Protocol: When to Change?

Don’t wait until the blade is round.

1. Amperage Monitor: A sharp machine idles at low amps and cuts with stable spikes. A dull machine draws high continuous amps.

2. Fines Percentage: Dull blades “mash” plastic instead of cutting, creating excessive dust (fines). If your dust collector is filling up 2x faster, check your gap.

3. The Gap (Cutting Distance): The distance between Rotor and Stator should be 0.3mm – 0.5mm for film, and 1.0mm – 2.0mm for rigid pipes. Maintain this precision.

FAQ

Why are my D2 blades chipping?

You likely have metal contamination, or your feed rate is too aggressive (shock loading). Switch to DC53 for better impact resistance or install a magnetic separator on the infeed.

Can I sharpen shredder blades myself?

Yes, but you require a Surface Grinder with coolant. Never use a dry angle grinder; the localized heat will anneal (soften) the steel, ruining the edge instantly.

What is the cost difference?

DC53 blades often cost more than D2, but they can last meaningfully longer in impact-prone applications. Realized life depends on contamination, hardness targets, heat treatment quality, and knife geometry—so compare suppliers using cost-per-ton and trial data rather than a single percentage.

References

[1] “Tool Steels: Properties and Applications,” ASM International. Tool Steels: Properties and Applications

[2] “Heat Treatment of Gears and Cutting Tools,” Industrial Heating Magazine. Heat Treatment of Gears and Cutting Tools