Dans le monde en constante évolution du recyclage du plastique, des équipements de manutention performants constituent la clé de voûte de la réussite des opérations. Parmi les composants essentiels qui garantissent un flux de travail fluide et une productivité optimale, le bac de déchargement à vis s'impose comme un équipement indispensable. Ce guide complet explore tout ce que les professionnels du recyclage industriel doivent savoir sur les bacs de déchargement à vis, de leur fonctionnement fondamental aux critères de sélection avancés.

Qu'est-ce qu'un Bac de déchargement à vis?

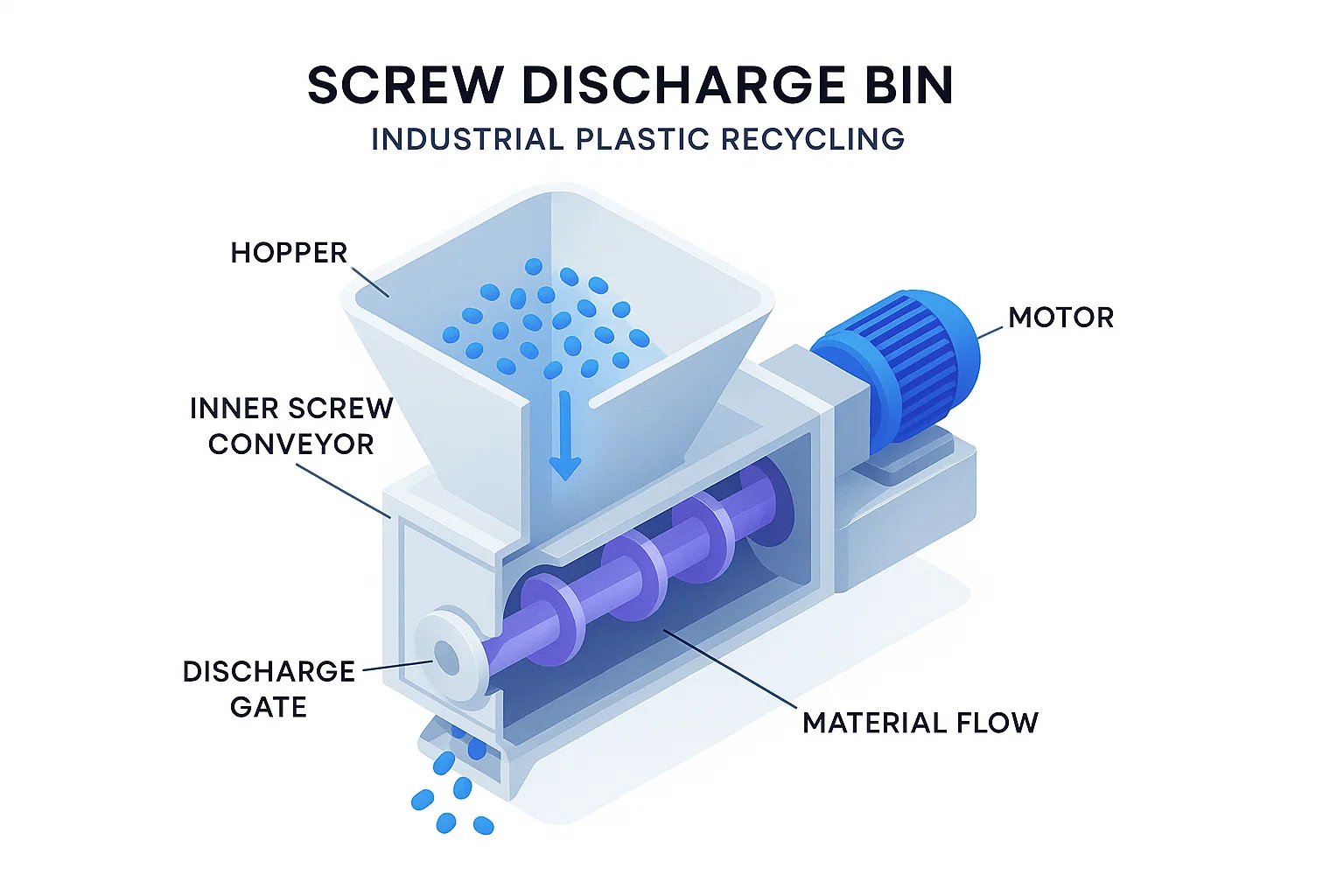

Un conteneur à vis sans fin est un système spécialisé de stockage et de manutention conçu pour recevoir, stocker et décharger systématiquement les matières plastiques traitées dans les installations de recyclage. Contrairement aux conteneurs à alimentation gravitaire classiques, ces unités intègrent un mécanisme de convoyeur à vis interne qui assure un flux de matières contrôlé et continu tout en évitant la formation de voûtes, de trous de rat et autres problèmes courants de déchargement liés aux matières plastiques en vrac.

La conception fondamentale consiste en une trémie ou un silo robuste équipé d'une vis sans fin ou d'un convoyeur à vis interne positionné au point de déchargement. Cette configuration assure un débit de matière constant et élimine les schémas de décharge irréguliers susceptibles de perturber les équipements de traitement en aval.

Composants clés et caractéristiques de conception

Éléments structurels primaires

Structure du bacGénéralement fabriqué en acier robuste ou en acier inoxydable, le bac présente des parois inclinées optimisées pour le flux de matériaux. Les surfaces internes sont souvent polies ou revêtues pour réduire les frottements et empêcher l'adhérence des matériaux.

Ensemble de convoyeur à vis:Le cœur du système comprend une vis hélicoïdale montée sur un arbre central, conçue avec des rapports de pas et de diamètre spécifiques pour gérer efficacement différents types de matériaux plastiques.

Système d'entraînement:Une combinaison de moteur à vitesse variable et de boîte de vitesses permet un contrôle précis des débits de décharge, permettant aux opérateurs d'adapter la production aux exigences de l'équipement en aval.

Porte de décharge:Un mécanisme de porte réglable à la sortie du bac permet un réglage précis des caractéristiques du flux de matière et un arrêt complet lorsque cela est nécessaire.

Fonctionnalités avancées

Les bacs de déchargement à vis modernes intègrent des fonctionnalités sophistiquées telles que des capteurs de niveau, des systèmes de vibration pour les matériaux difficiles et des systèmes de contrôle automatisés qui s'intègrent parfaitement aux réseaux de contrôle de processus à l'échelle de l'usine.

Comment fonctionnent les bacs à déchargement à vis

Le principe de fonctionnement repose sur la rotation contrôlée de la vis sans fin interne. Lorsque les matières plastiques pénètrent dans le silo par le haut, elles se déposent autour du mécanisme de la vis. Lorsqu'une décharge est nécessaire, la vis tourne à des vitesses prédéterminées, créant un déplacement positif qui déplace les matières vers la sortie de décharge.

Cette action mécanique neutralise la tendance naturelle des paillettes, granulés ou poudres de plastique à former des ponts ou à créer des écoulements irréguliers. L'agitation douce et continue assurée par la vis garantit le maintien des propriétés d'écoulement des matériaux tout au long du stockage.

Dynamique des flux de matières

La conception hélicoïdale de la vis crée un flux premier entré, premier sorti, empêchant la ségrégation des matériaux et garantissant une qualité constante du produit déchargé. Le contrôle du flux élimine les pulsations et les à-coups fréquents dans les systèmes à alimentation gravitaire, assurant ainsi un flux de matériaux régulier vers les équipements en aval.

Applications dans le recyclage du plastique

Applications de traitement primaire

Stockage après lavageAprès les opérations de lavage, les paillettes de plastique humides nécessitent une évacuation contrôlée pour éviter le compactage et assurer un drainage adéquat. Les trémies d'évacuation à vis sont idéales pour cette application, car elles maintiennent le mouvement du matériau sans endommager les paillettes fragiles.

Manipulation des granulésAprès les opérations de granulation, les granulés de plastique chauds nécessitent un refroidissement et une décharge contrôlés. Le fonctionnement en douceur des trémies de déchargement à vis prévient la déformation des granulés tout en maintenant un débit constant vers les équipements de conditionnement ou de transformation ultérieure.

Intégration du traitement secondaire

Opérations de mélange:Lorsque plusieurs flux de plastique nécessitent un mélange, les bacs de déchargement à vis peuvent être configurés en parallèle pour fournir un contrôle précis du débit pour des rapports de mélange précis.

Points de contrôle de qualité:Le placement stratégique des bacs de déchargement à vis crée des points d'échantillonnage naturels où le personnel de contrôle qualité peut surveiller les caractéristiques des matériaux sans perturber le flux de production.

Types et configurations

Configurations standard

Systèmes à vis unique:La configuration la plus courante, comprenant un convoyeur à vis optimisé pour les applications de manutention de plastique à usage général.

Arrangements à double vis:Pour les opérations à grande capacité ou les matériaux difficiles, les systèmes à double vis offrent un débit accru et des caractéristiques de manutention des matériaux améliorées.

Conceptions spécialisées

Poubelles chauffées:Pour les matériaux nécessitant un maintien de la température, les bacs de déchargement à vis chauffés intègrent des systèmes de chauffage à vapeur ou électrique pour empêcher la solidification du matériau.

Modèles étanches à la poussière:Lors de la manipulation de poudres plastiques fines ou de matériaux poussiéreux, les conceptions scellées avec des ports de collecte de poussière maintiennent des environnements de travail propres.

Versions sanitaires:Pour le recyclage du plastique de qualité alimentaire, des finitions de surface spéciales et des capacités de lavage garantissent le respect des normes d'hygiène.

Avantages pour les opérations industrielles

Avantages opérationnels

Débits constants:Contrairement aux systèmes alimentés par gravité qui peuvent connaître des taux de décharge variables, les bacs de décharge à vis maintiennent un rendement constant quel que soit le niveau ou les caractéristiques du matériau.

Besoins en main-d'œuvre réduits:Le fonctionnement automatisé élimine le besoin d’intervention manuelle pour éliminer les blocages ou redémarrer le flux de matériaux.

Sécurité améliorée:La conception fermée et les systèmes de décharge mécanique réduisent l'exposition des travailleurs aux matériaux et éliminent le besoin d'agitation manuelle des bacs.

Avantages économiques

Débit accru:Un flux de matériaux constant évite la pénurie d'équipements en aval, maximisant ainsi l'efficacité globale de la ligne et la capacité de production.

Maintenance réduite:L’élimination des ponts et des blocages de matériaux réduit l’usure des équipements en aval et diminue les besoins de maintenance imprévus.

Cohérence de la qualité:Le rejet contrôlé maintient l’intégrité du matériau et réduit les risques de contamination.

Critères de sélection et spécifications

Considérations relatives à la capacité

Un dimensionnement approprié nécessite une analyse minutieuse des cadences de production en amont, des besoins en équipements en aval et de la capacité de stockage souhaitée. Les meilleures pratiques du secteur suggèrent de dimensionner les silos de manière à assurer 15 à 30 minutes de stockage à des cadences de production maximales.

Compatibilité des matériaux

Les différents matériaux plastiques présentent des caractéristiques d'écoulement variables. Les paillettes de PET se comportent différemment des granulés de PEHD, ce qui nécessite des conceptions de vis et des paramètres de fonctionnement spécifiques. Les principaux points à considérer sont les suivants :

- Masse volumique apparente du matériau

- Distribution granulométrique

- Teneur en humidité

- Exigences de température

- Caractéristiques d'abrasivité

Exigences d'intégration

Les installations de recyclage modernes fonctionnent comme des systèmes intégrés où les interfaces des équipements sont essentielles. Les facteurs d'intégration essentiels comprennent :

- Compatibilité du système de contrôle

- Contraintes d'espace physique

- Exigences d'accès pour la maintenance

- Intégration du système de sécurité

Installation et maintenance

Meilleures pratiques d'installation

Une installation correcte commence par une conception adéquate des fondations, capable de supporter le poids du conteneur à pleine charge et les charges dynamiques du mécanisme à vis. Les connexions structurelles doivent supporter la dilatation thermique et les vibrations, tout en maintenant un alignement précis des composants d'entraînement.

L'installation électrique requiert une attention particulière à la protection du moteur, à la compatibilité des variateurs de fréquence et à l'intégration aux systèmes de contrôle-commande de l'usine. Les systèmes de sécurité, notamment les arrêts d'urgence, les verrouillages d'accès et les alarmes de niveau, doivent être correctement configurés et testés.

Programmes de maintenance préventive

Le bon fonctionnement dépend de programmes de maintenance réguliers traitant des principaux points d’usure et des composants du système.

Inspections quotidiennes:Contrôles visuels des taux de décharge, des bruits inhabituels ou des vibrations qui pourraient indiquer des problèmes en développement.

Entretien hebdomadaire: Lubrification des points d'appui, contrôle de la tension de la courroie d'entraînement et vérification du fonctionnement du système de contrôle.

Services mensuels:Inspection détaillée de l'usure des vis, contrôles de l'alignement des arbres et étalonnage des capteurs de niveau et des régulateurs de débit.

Révisions annuelles:Inspection complète du système d'entraînement, remplacement des roulements si nécessaire et test complet du système de sécurité.

Dépannage des problèmes courants

Problèmes de débit

Des débits de décharge irréguliers indiquent souvent une usure des filets de vis ou une modification des caractéristiques des matériaux. Un dépannage systématique consiste à vérifier l'usure des vis, le fonctionnement du système d'entraînement et l'analyse des propriétés des matériaux.

Pontage matériel

Malgré l'agitation mécanique, certains matériaux peuvent encore former des ponts dans certaines conditions. Les solutions incluent l'ajustement de la vitesse de la vis, la modification des paramètres de la vanne de décharge ou l'installation d'aides à l'écoulement supplémentaires.

Problèmes de système d'entraînement

Les surcharges de moteur résultent généralement d'un compactage des matériaux, d'une contamination par des corps étrangers ou d'un grippage mécanique. Un diagnostic précis nécessite une vérification systématique des systèmes électriques, des composants mécaniques et de l'état des matériaux.

Développements et innovations futurs

L'industrie du recyclage du plastique continue d'évoluer, stimulant l'innovation dans les équipements de manutention. Parmi les tendances émergentes figurent les capteurs intelligents pour la maintenance prédictive, les matériaux avancés pour une meilleure résistance à l'usure et les systèmes intégrés optimisant la consommation d'énergie tout en maximisant le rendement.

Les applications d’intelligence artificielle et d’apprentissage automatique commencent à apparaître dans les systèmes de contrôle de processus, permettant des ajustements prédictifs basés sur les caractéristiques des matériaux et les exigences de production.

Conclusion

Bacs de déchargement à vis Ils représentent un investissement crucial dans les opérations modernes de recyclage du plastique, assurant la manutention contrôlée des matériaux nécessaire à une production efficace et constante. Leur capacité à traiter divers matériaux plastiques tout en maintenant des débits constants les rend indispensables aux installations cherchant à optimiser leur rendement et la qualité de leurs produits.

Pour les acheteurs d'équipements de recyclage industriel, comprendre les capacités et les exigences des bennes à vis sans fin permet de prendre des décisions éclairées et de garantir la réussite opérationnelle à long terme. Alors que l'industrie du recyclage progresse vers une efficacité et une automatisation accrues, ces systèmes robustes et fiables resteront essentiels à la réussite des opérations.

Lors de l'évaluation des bennes à vis pour votre installation, tenez compte non seulement des besoins immédiats, mais aussi des projets d'expansion futurs et de l'évolution des besoins en manutention. Un choix et une installation judicieux de ces systèmes constituent la base d'un fonctionnement fiable et efficace de votre installation de recyclage du plastique pendant de nombreuses années.